Rapid preparation method of gadolinium zirconate ceramics

A technology of gadolinium zirconate and ceramics, which is applied in the field of rapid preparation of gadolinium zirconate ceramics, can solve the problems of low density of sintered samples, secondary pollution, long sintering time, etc., achieve good industrial application prospects, fast heating speed, The effect of short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A rapid preparation method of gadolinium zirconate ceramics, comprising the following steps:

[0029] ① Fully mix gadolinia and zirconia powder raw materials at a molar ratio of 1:2 (the purity of gadolinia and zirconia is above 98%), and then fully grind them into mixture particles with a particle size of 150 mesh (0.1mm ).

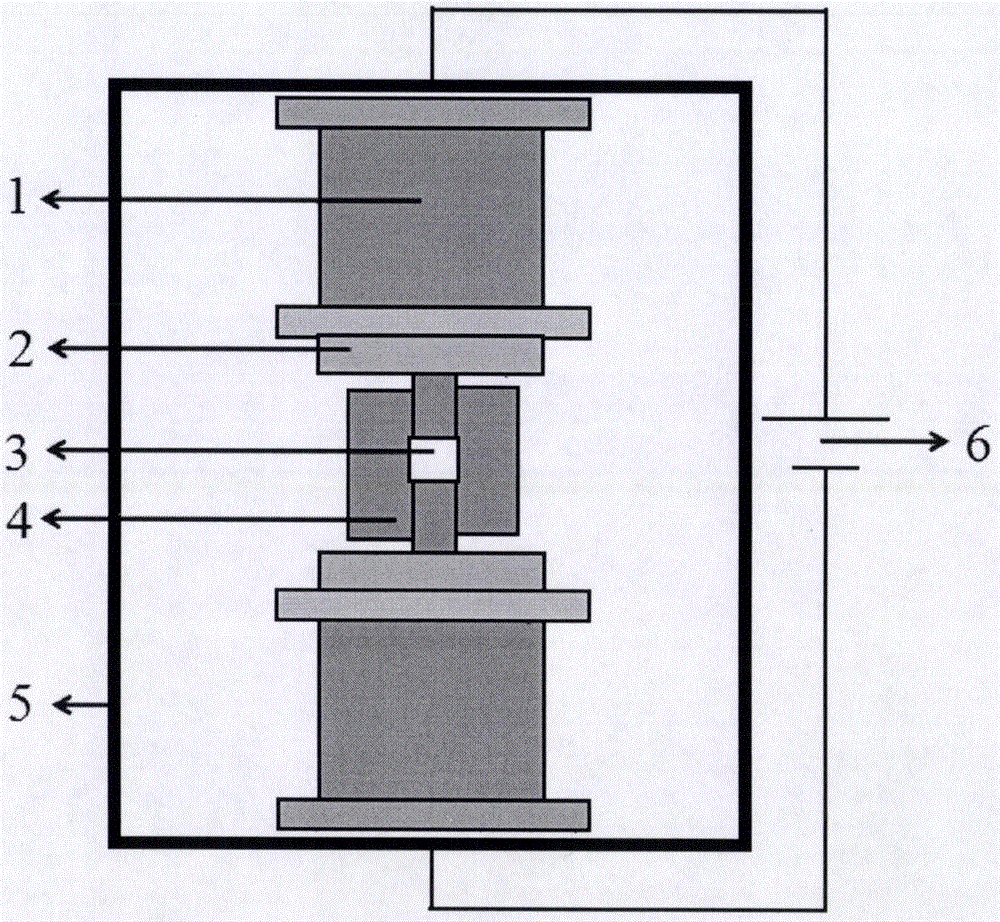

[0030] ② A layer of carbon paper is added to a graphite abrasive tool with a diameter of 15 mm, and then the mixture particles are put into a graphite mold 4 and pre-pressed under a pressure of 10 MPa.

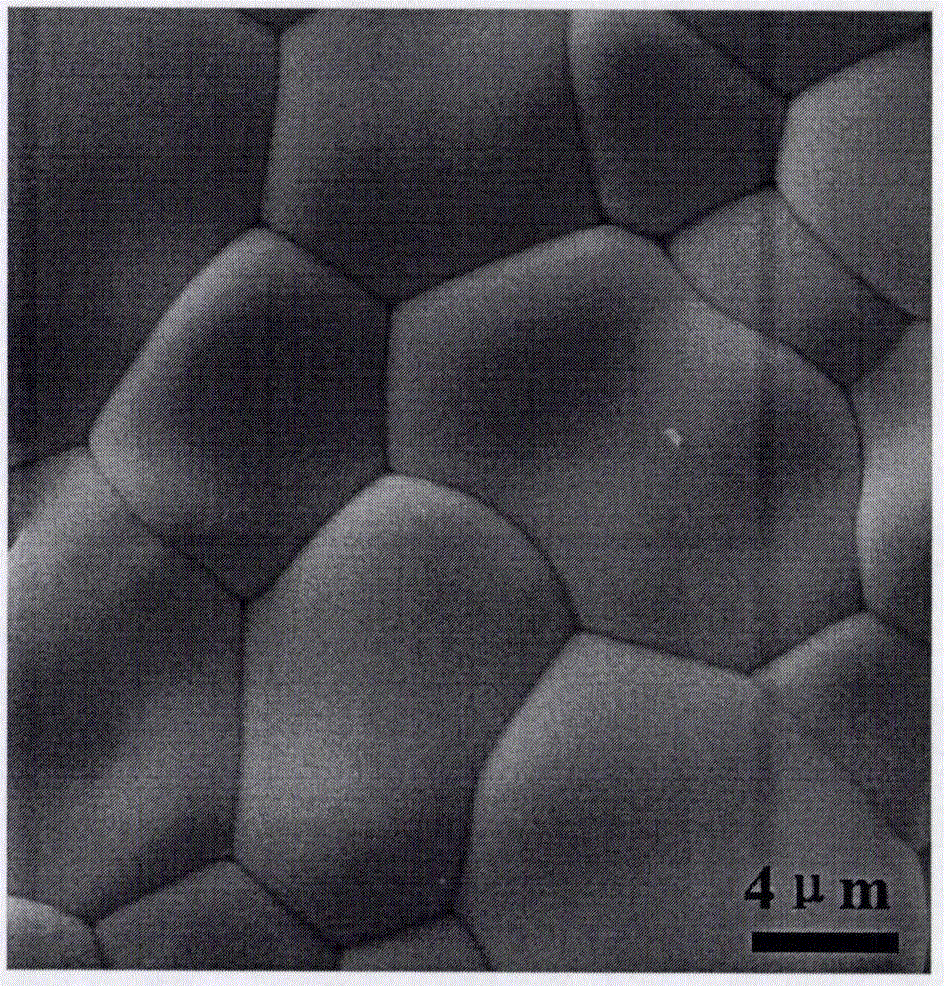

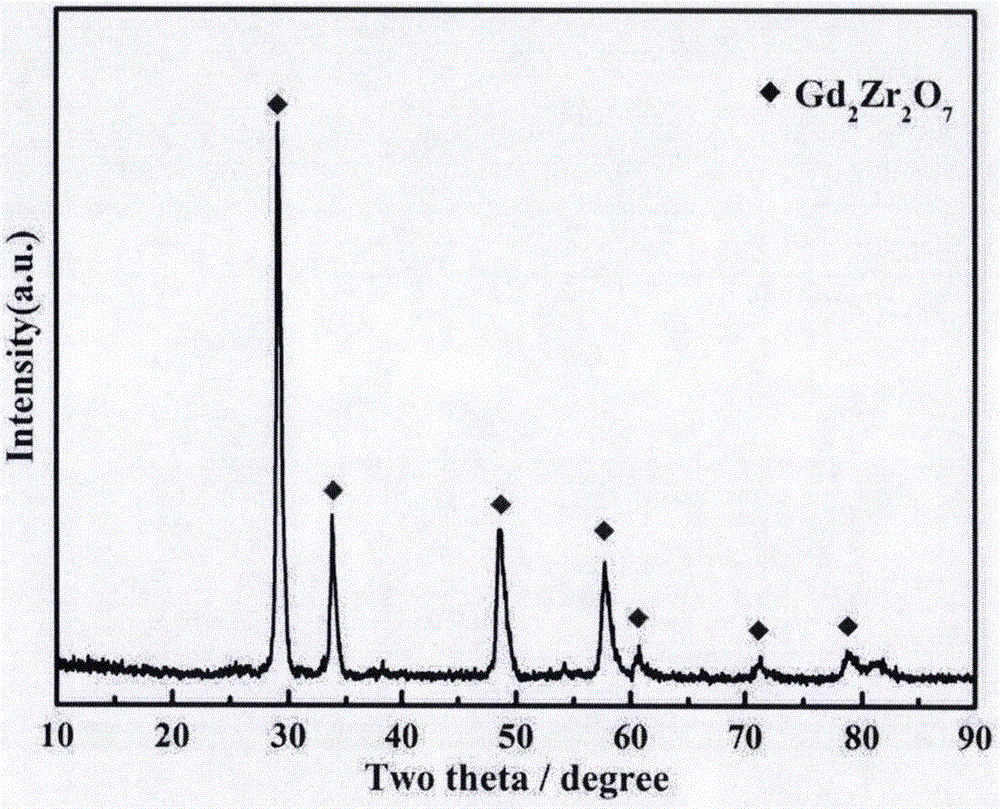

[0031] ③Put the graphite mold containing the mixture particles into the spark plasma sintering device, connect the DC voltage, and vacuumize for 15 minutes (the general pressure is 10-20Pa), and heat it from room temperature 28°C to 1700°C at a heating rate of 100°C / min , and then kept at 1700°C for 5 minutes, and finally turned off the power, cooled to room temperature naturally, and took out the sample. After the reaction, put the obtained gad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com