Fabrication method of substrate with charge trap and insulating buried layer

A charge trap and insulating buried layer technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of device circuit signal loss, weaken the high-resistance characteristics of the support layer, etc., and achieve the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the method for preparing a substrate with a charge trap and an insulating buried layer provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

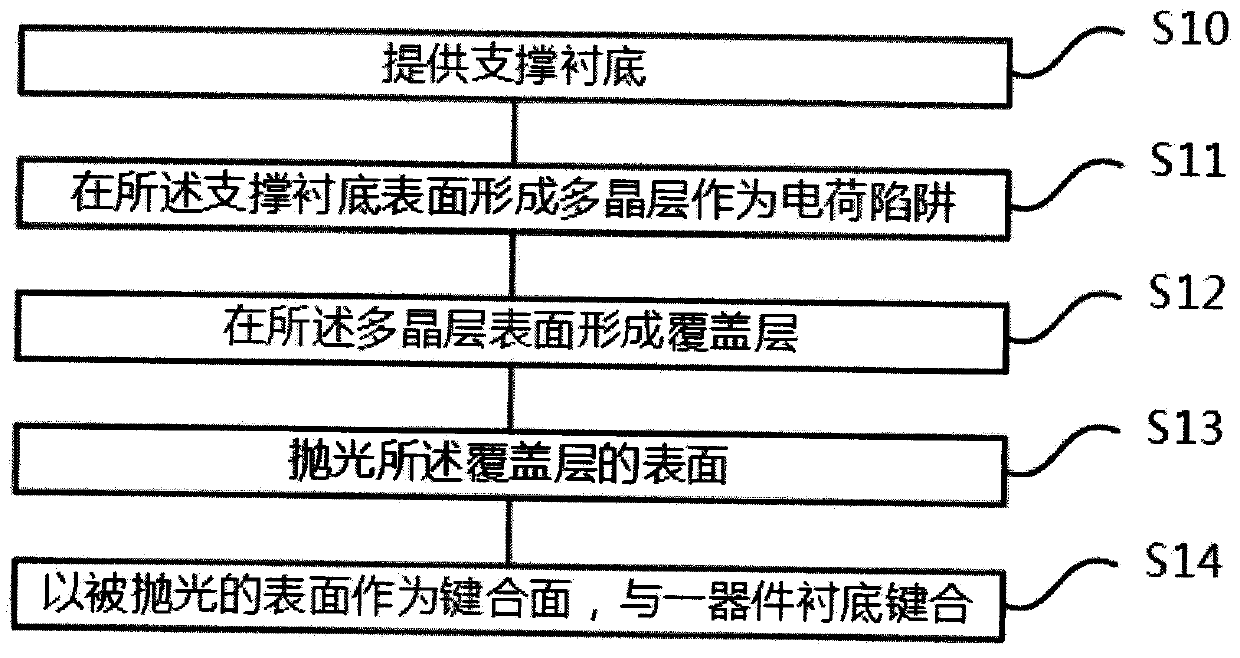

[0014] attached figure 1 Shown is a schematic diagram of the implementation steps of this specific embodiment, including: step S10, providing a support substrate; step S11, forming a polycrystalline layer on the surface of the support substrate as a charge trap; step S12, forming a charge trap on the surface of the polycrystalline layer Forming a cover layer; step S13, polishing the surface of the cover layer; step S14, using the polished surface as a bonding surface, and bonding with a device substrate.

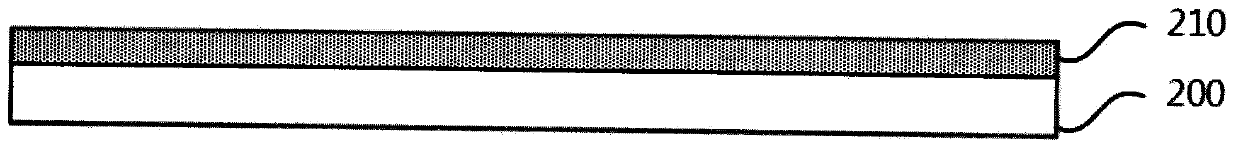

[0015] attached Figure 2A to attach Figure 2D Shown is the process schematic diagram of this specific embodiment.

[0016] attached Figure 2A As shown, and referring to step S10, a supporting substrate 200 is provided. The suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com