Inlaid type handle

An inlaid, handle technology, applied in the direction of handle connection, wing fan handle, wing fan ball handle, etc., can solve the problems of potential safety hazards, cumbersomeness, increase production cost, etc., and achieve novel and unique structural design and production. The effect of energy saving and environmental protection in the process and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

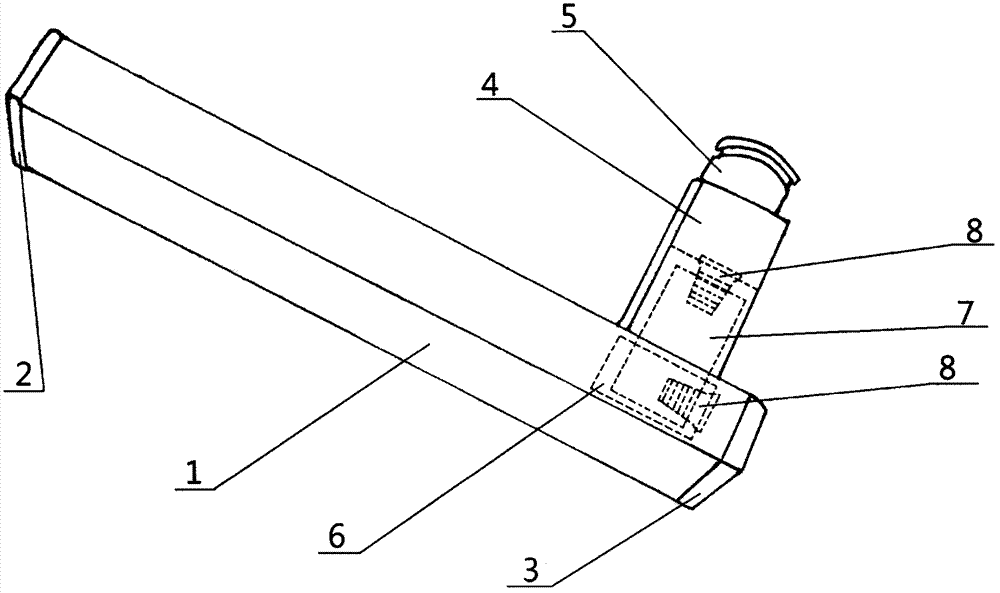

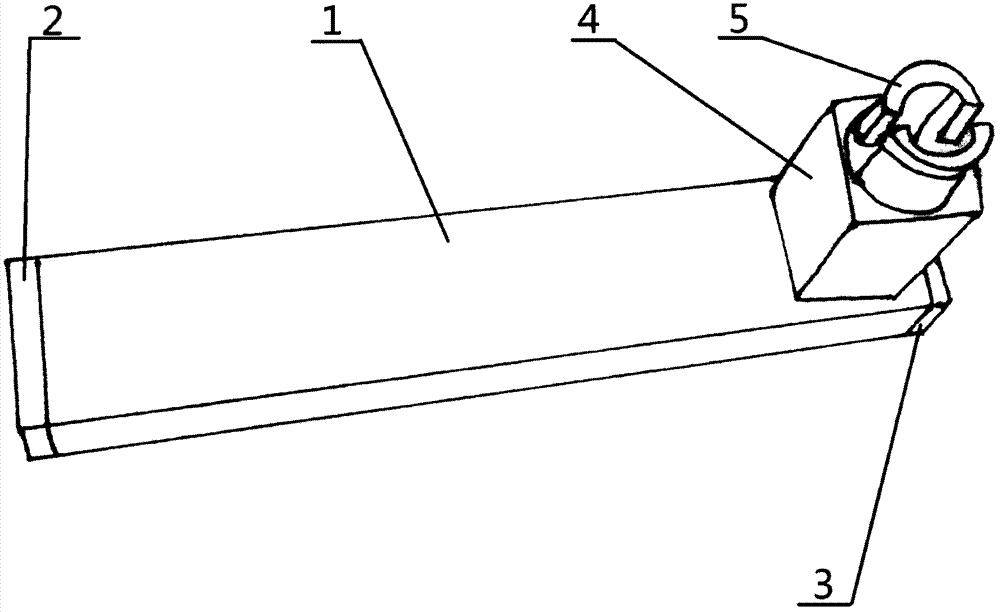

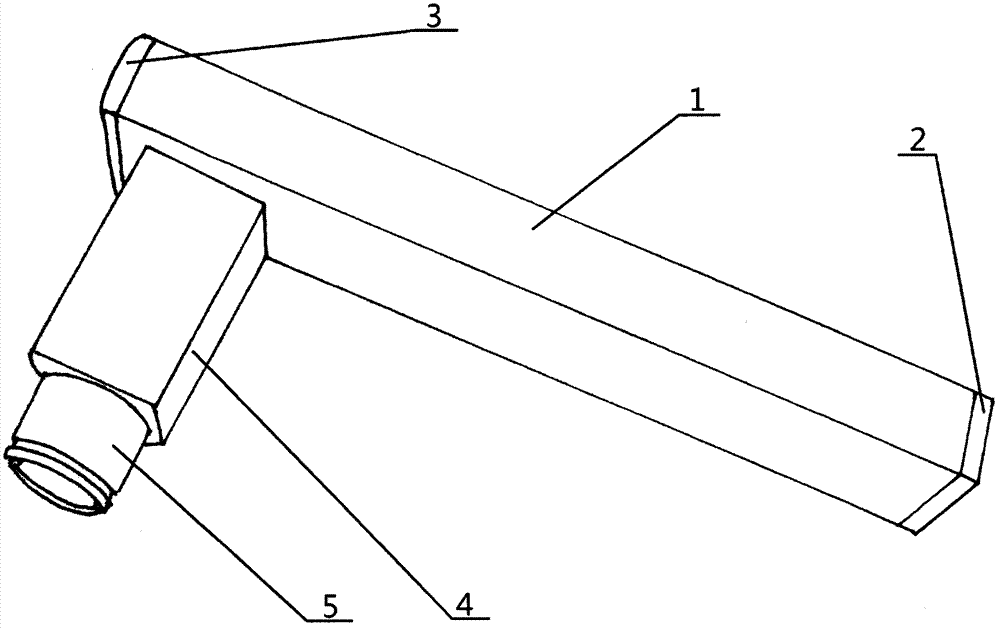

[0047] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0048] The present invention is composed of handle (1), plug one (2), plug two (3), connector (4), handle (5), fastening seat (6), fastening connector (7), Screws (8) form.

[0049] figure 1 , figure 2 and image 3 Shown is the structural representation of the present invention. Wherein, 1 is a handle, 2 is a plug one, 3 is a plug two, 4 is a connector, 5 is a handle, 6 is a fastening seat, 7 is a fastening connector, and 8 is a screw.

[0050] Figure 4 It is a structural schematic diagram of the handle (1) in the present invention. The handle (1) is a square inner hollow pipe body, and a connector placement hole (9) is arranged on the top of the front end of the handle (1).

[0051] Figure 5 It is a structural schematic diagram of plug one (2) in the present invention. Plug one (2) is made up of end cap one (10) and sleeve head one (11).

[0052] Figure 6 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com