A method and system for in-situ measurement of the surface accuracy of a composite mold for an antenna reflector

An antenna reflector and mold profile technology, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of many times of transportation of composite molds, long time-consuming point-by-point touch measurement, and large influence of measurement accuracy errors. Improve data processing efficiency, efficient automatic collection, and the effect of fewer operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

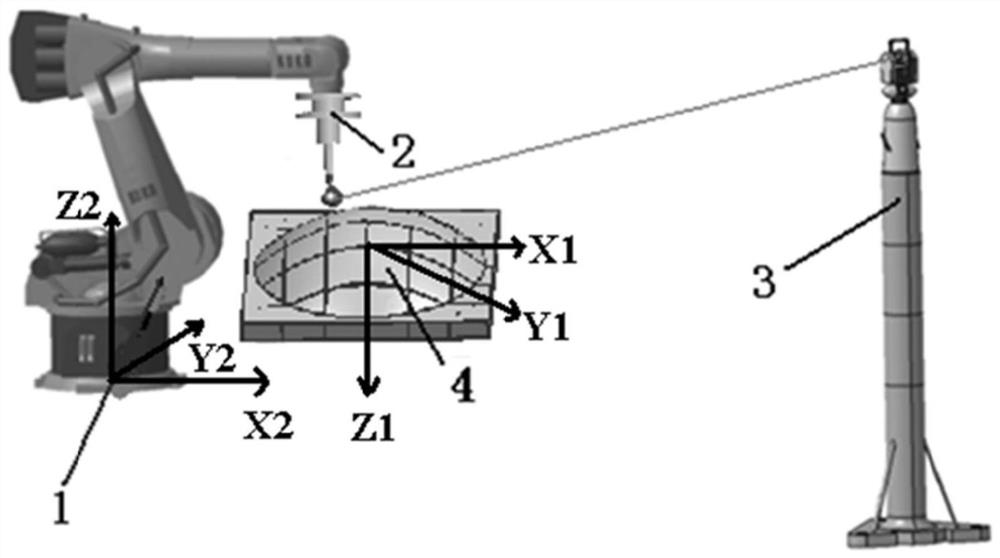

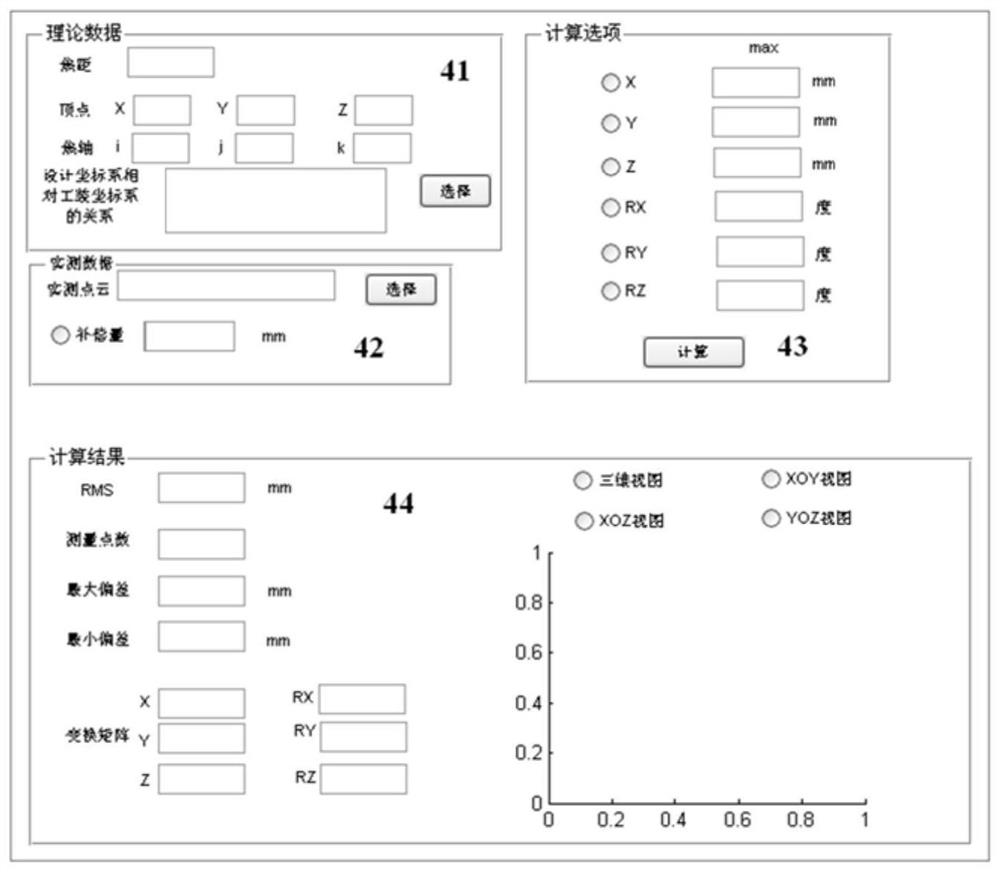

[0044] An in-situ measurement method for the surface accuracy of an antenna reflector composite mold, the specific steps are as follows:

[0045] (1) Obtain the three-dimensional model for making the composite material mold to be measured, and establish the workpiece coordinate system of the three-dimensional model, and preset the points to be measured on the surface of the three-dimensional model;

[0046] (2) According to step (1), preset the points to be measured to determine the measurement path of the six-degree-of-freedom robot in the workpiece coordinate system;

[0047] (3) After assembling the composite mold to be measured in place, establish a six-degree-of-freedom robot base coordinate system, obtain the coordinate transformation matrix of the robot base coordinate system and the workpiece coordinate system, and convert the measurement path obtained in step (2) into the base coordinate system The measuring path of the target ball;

[0048] (4) According to the targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com