An anti-vibration stone processing device

A stone processing and anti-vibration technology, applied in metal processing equipment, grinding drive devices, manufacturing tools, etc., can solve the problems of reducing stone polishing efficiency, affecting the effect of stone surface grinding, and stone surface transition grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

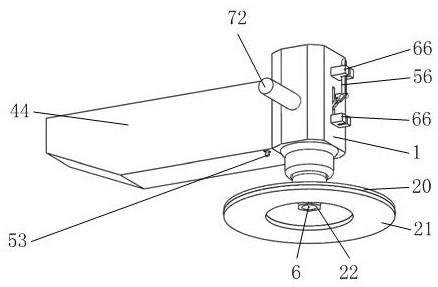

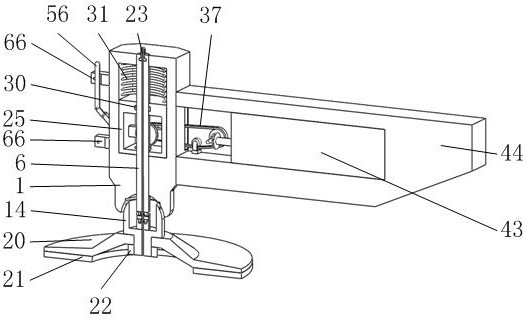

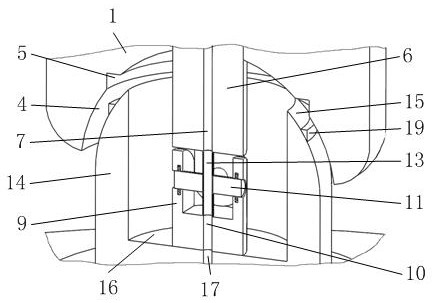

[0040] Such as figure 1 , 2 , 6, it includes machine head shell 1, shaft A6, connecting column 9, cross shaft 11, installation head 14, ring A19, disc seat 20, polishing sheet 21, nut 22, slider A25, scroll spring 29, Spring A31, bevel gear D32, bevel gear C33, shaft C34, fixed seat A35, pulley B36, belt 37, pulley A38, bushing 39, bevel gear B40, shaft B41, bevel gear A42, electric drive module 43, machine Body shell 44, chute 45, hold-up wheel 47, slide block B49, spring B51, slide block C52, screw rod 53, internal thread sleeve 55, wherein as figure 2 As shown, the axis A6 and the head shell 1 rotate in the circumferential direction and slide in the axial direction; figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com