Grinding equipment for air conditioner accessory machining

A technology for accessories and equipment, applied in the field of grinding equipment for processing air-conditioning accessories, can solve the problems of low efficiency and high labor intensity of workers, and achieve the effect of reducing labor intensity and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

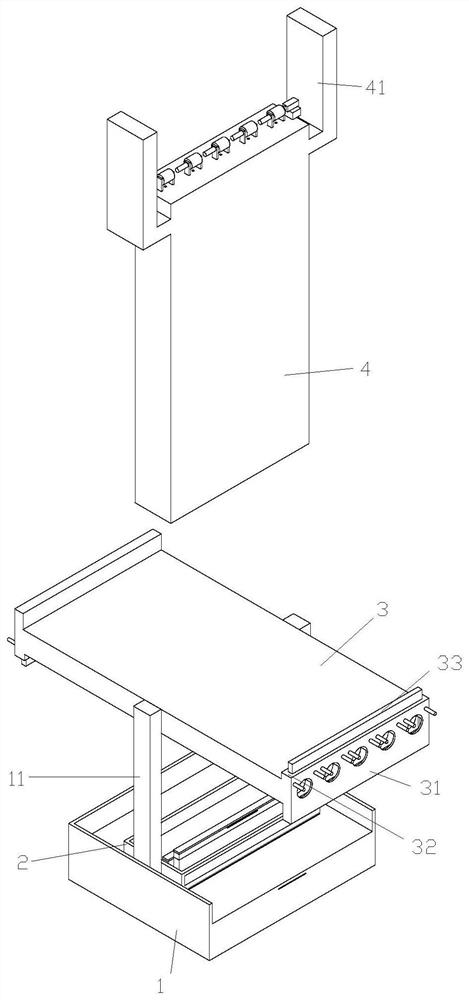

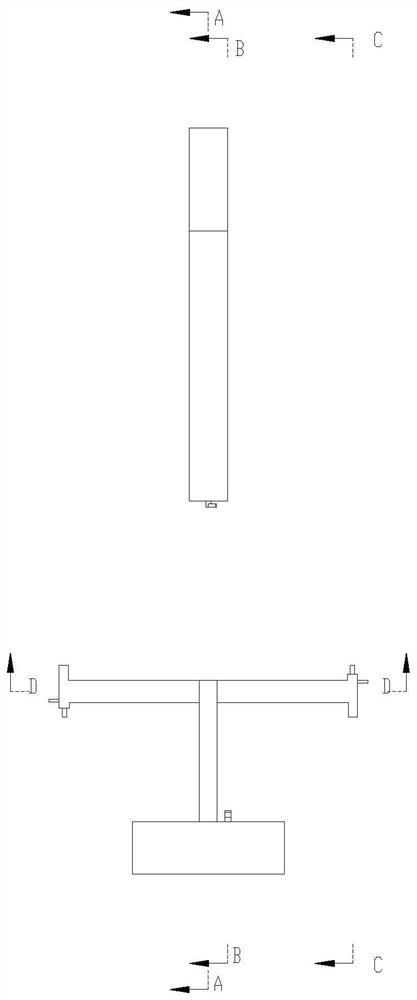

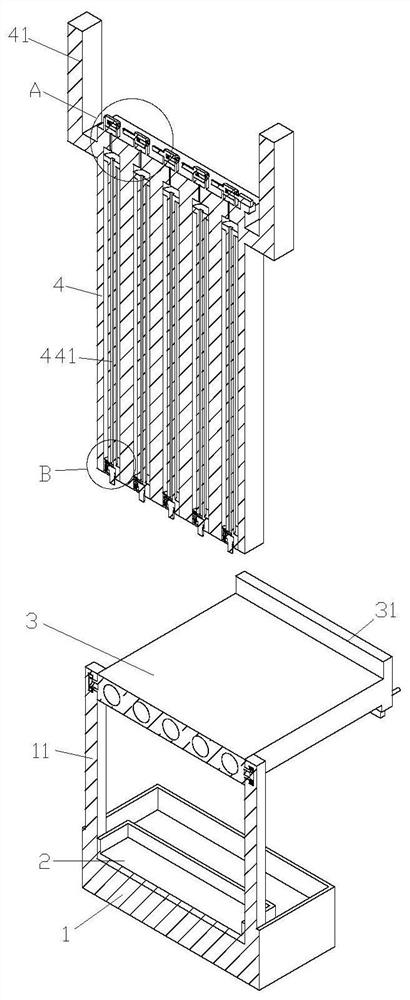

[0042] Such as Figure 1-26 As shown, a kind of grinding equipment for processing air-conditioning accessories, including a base 1, a support rod 11 arranged on the base 1, and a loading plate 3 rotatably connected to the support rod 11, the loading plate 3 There are multiple loading chambers on the top, the inner wall of the loading chamber is provided with a first movable groove, a first connecting spring 351 is arranged in the first movable groove, and a fixed block is arranged at one end of the first connecting spring 351 35; a first mounting plate 4 is provided above the loading plate 3, and a plurality of second movable grooves matching with the loading cavity are arranged on the first mounting plate 4, and inside the second movable grooves An installation block 44 is provided, and the installation block 44 is provided with a grinding block 453 and a first motor 45 for driving the rotation of the grinding block 453; the refrigerant pipe to be processed is placed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com