Preparation method and application of tellurium-based precious metal alloy nanowire catalyst

A technology of tellurium nanowires and alloy nanometers, which is applied in the field of catalyst preparation, can solve the problems of insufficient utilization of Te nanowires, failure to meet industrialization requirements, and limited applications, so as to reduce the amount of precious metals, prevent catalytic activity and stability from being reduced, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Disperse 0.05 mmol of tellurium nanowires in 30 mL of ethylene glycol solution, place in a conical flask (50 mL), and put K 2 PtCl 4 (0.012mmol) and K 2 PdCl 4 (0.006mmol) ethylene glycol solution 0.72mL, under the condition of magnetic stirring, the stirring speed is 300rpm, add dropwise (30 drops / min), after the dropwise addition, put it into the shaker, at 260rpm and 50 degrees Celsius Under conditions, react for 8 hours. Then add 100mL acetone to the reaction system to extract the product, centrifuge and wash three times with ethanol to get the final sample Pt 26 PD 15 Te 59 nanowire catalysts.

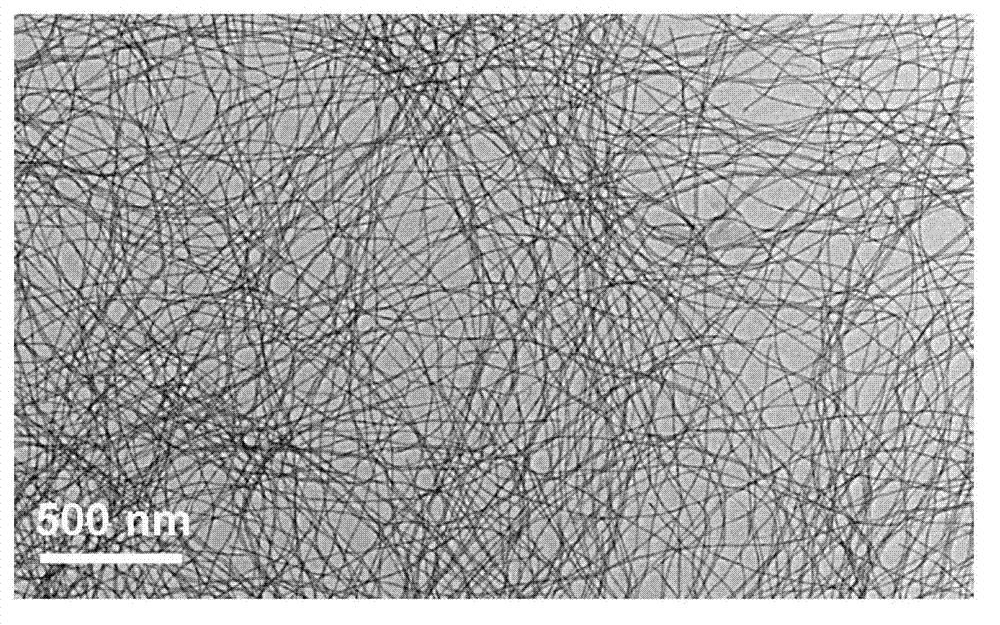

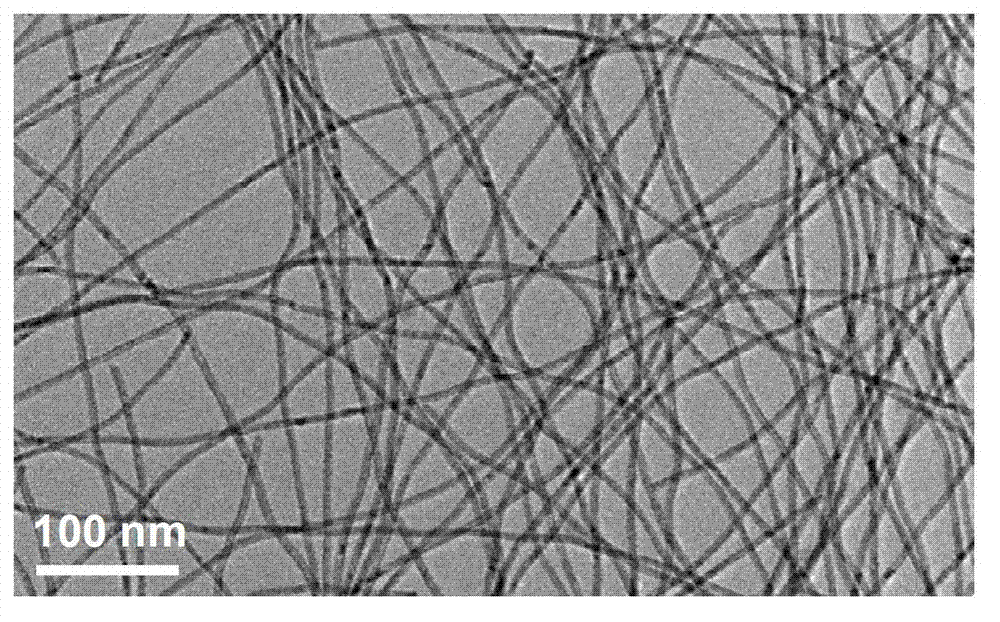

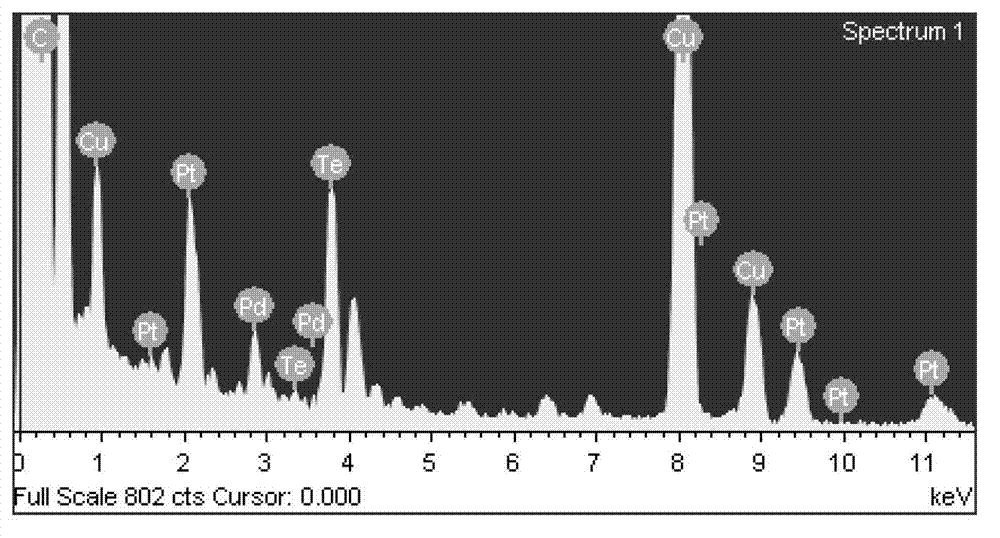

[0052] For the Pt 26 PD 15 Te 59 The nanowires were observed by transmission electron microscopy, and the results can be found in figure 1 , 2 , figure 1 , 2 For the Pt provided by Example 1 of the present invention 26 PD 15 Te 59 TEM images of the nanowires, taken by figure 1 , 2 It can be seen that we have obtained a one-dimensional ultrafine nanowire ca...

Embodiment 2

[0054] Disperse 0.05 mmol of tellurium nanowires in 30 mL of ethylene glycol solution, put it into a conical flask (50 mL), and put K 2 PtCl 4 (0.009mmol) and K 2 PdCl 4 (0.009mmol) of ethylene glycol dissolved in 0.72mL, under the condition of magnetic stirring, the stirring speed is 300rpm, add dropwise (30 drops / min), after the dropwise addition, put it into the shaker, at 260rpm and 50 degrees Celsius Under conditions, react for 8 hours. Then add 100mL acetone to the reaction system to extract the product, centrifuge and wash three times with ethanol to get the final sample Pt 23 PD 23 Te 54 nanowire catalysts.

[0055] For the Pt 23 PD 23 Te 54 The nanowires were observed by transmission electron microscopy, and the results can be found in figure 1 , 2 , Figure 4 , 5 For the Pt provided by Example 2 of the present invention 23 PD 23 Te 54 TEM images of the nanowires, taken by Figure 4 , 5 It can be seen that we have obtained a one-dimensional ultrafine...

Embodiment 3

[0057] Disperse 0.05 mmol of tellurium nanowires in 30 mL of ethylene glycol solution, put it into a conical flask (50 mL), and put K 2 PtCl 4 (0.006mmol) and K 2 PdCl 4 (0.012mmol) of ethylene glycol dissolved in 0.72mL, under the condition of magnetic stirring, the stirring speed is 300rpm, add dropwise (30 drops / min), after the dropwise addition, put it into the shaker, at 260rpm and 50 degrees Celsius Under conditions, react for 8 hours. Then add 100mL acetone to the reaction system to extract the product, centrifuge and wash three times with ethanol to get the final sample Pt 15 PD 33 Te 52 nanowire catalysts.

[0058] For the Pt 15 PD 33 Te 52 The nanowires were observed by transmission electron microscopy, and the results can be found in figure 1 , 2 , Figure 7 , 8 For the Pt provided by Example 3 of the present invention 15 PD 33 Te 52 TEM images of the nanowires, taken by Figure 7 , 8 It can be seen that we have obtained a one-dimensional ultrafine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com