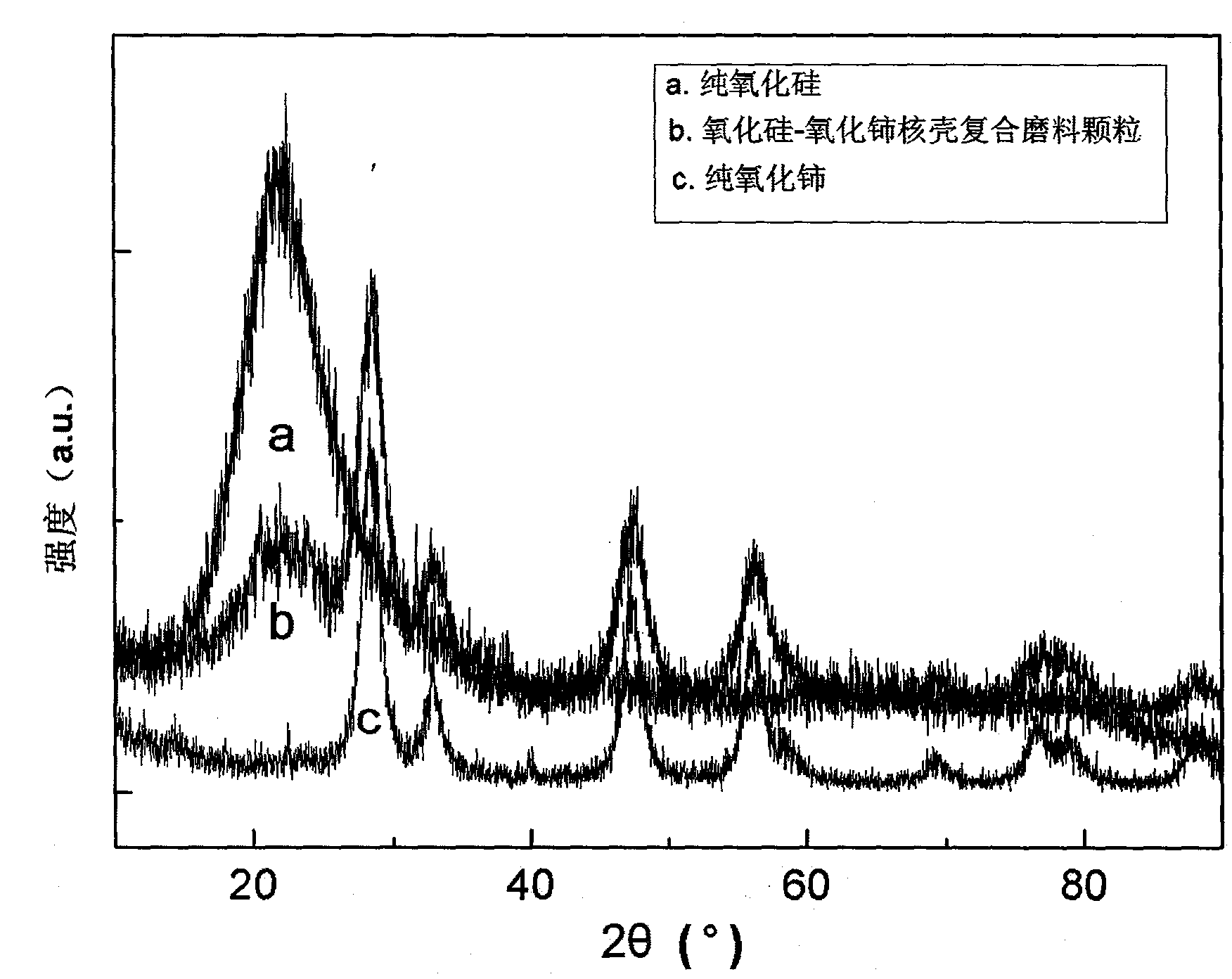

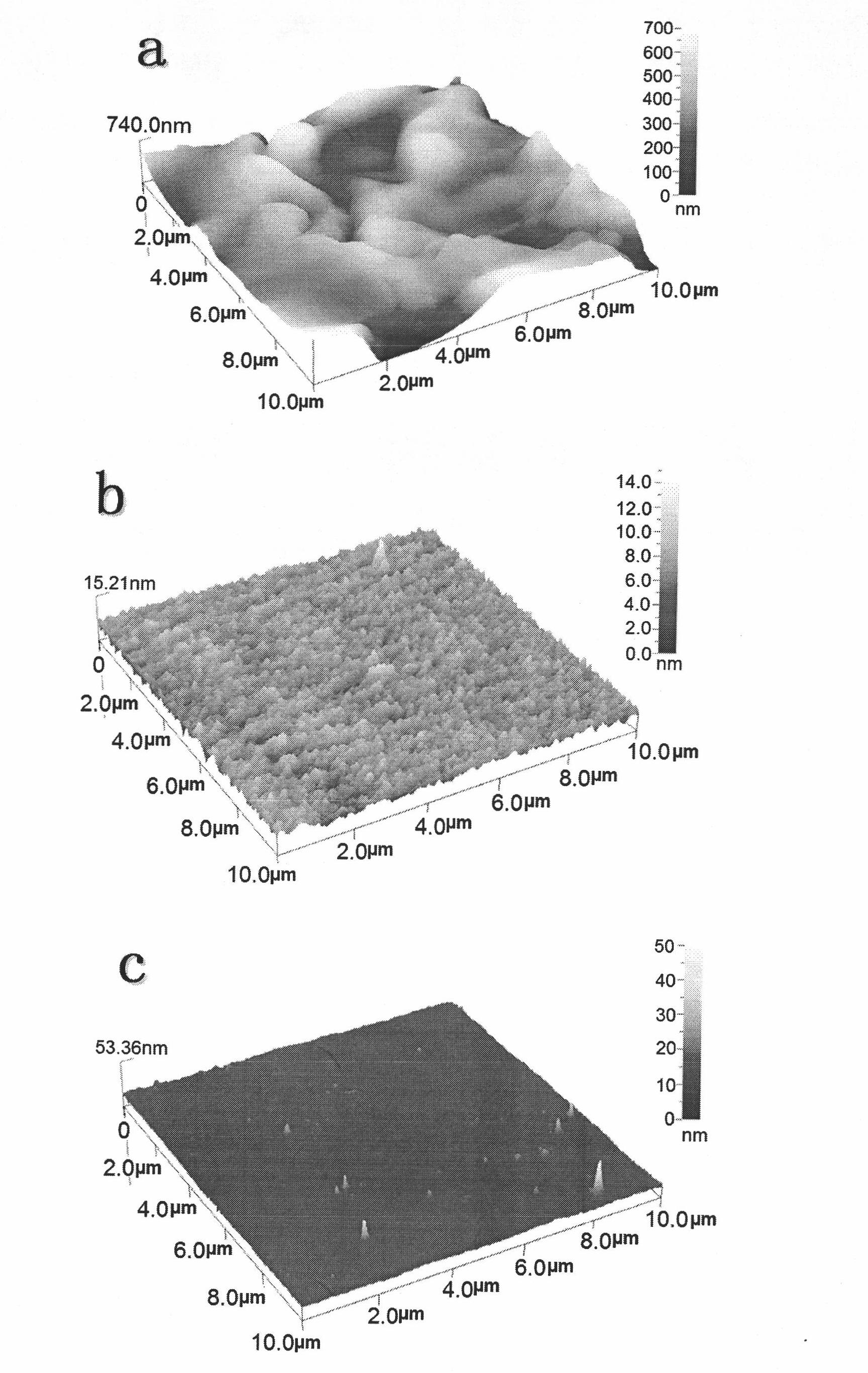

Silicon oxide-cerium oxide nuclear shell compounded abrasive granules, and preparation and application thereof

A composite abrasive and cerium oxide technology, which is applied in grinding/polishing equipment, chemical instruments and methods, grinding machines, etc., can solve problems affecting polishing effect, pollution of reaction waste liquid, secondary agglomeration of particles, etc., and achieve good industrial utilization value , save cost, improve the effect of low selection ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation steps of high-purity silica sol (wherein containing particle diameter is the silica abrasive particle of 80nm, and based on described high-purity silica sol abrasive, the weight percent of silica abrasive particle is 10%) are as follows:

[0050] 1) Initial purification: dilute water glass to SiO2 The weight content is no more than 15%, filter, and then exchange the filtrate with a cationic resin to remove sodium ions and other cationic impurities;

[0051] 2) Preparation of seed crystals: Adjust the pH of the initially purified liquid to 11.0, gradually heat up to 60-135°C under stirring conditions, carry out polymerization of seed crystals, and prepare silica sol with high uniformity after cooling;

[0052] 3) Increase the particle size: heat up the high-dispersion silica sol prepared in the seed crystal preparation process to 60~135°C under stirring conditions, add the liquid obtained from primary purification at a temperature not higher than 50°C, and...

Embodiment 2

[0058] The preparation of high-purity silica sol (wherein containing particle diameter is the silica abrasive particle of 140nm, and based on described high-purity silica sol abrasive, the weight percent of silica abrasive particle is 10%), preparation method is the same as embodiment 1 , wherein the step of increasing the particle size is repeated to obtain a high-purity silica sol with a larger particle size.

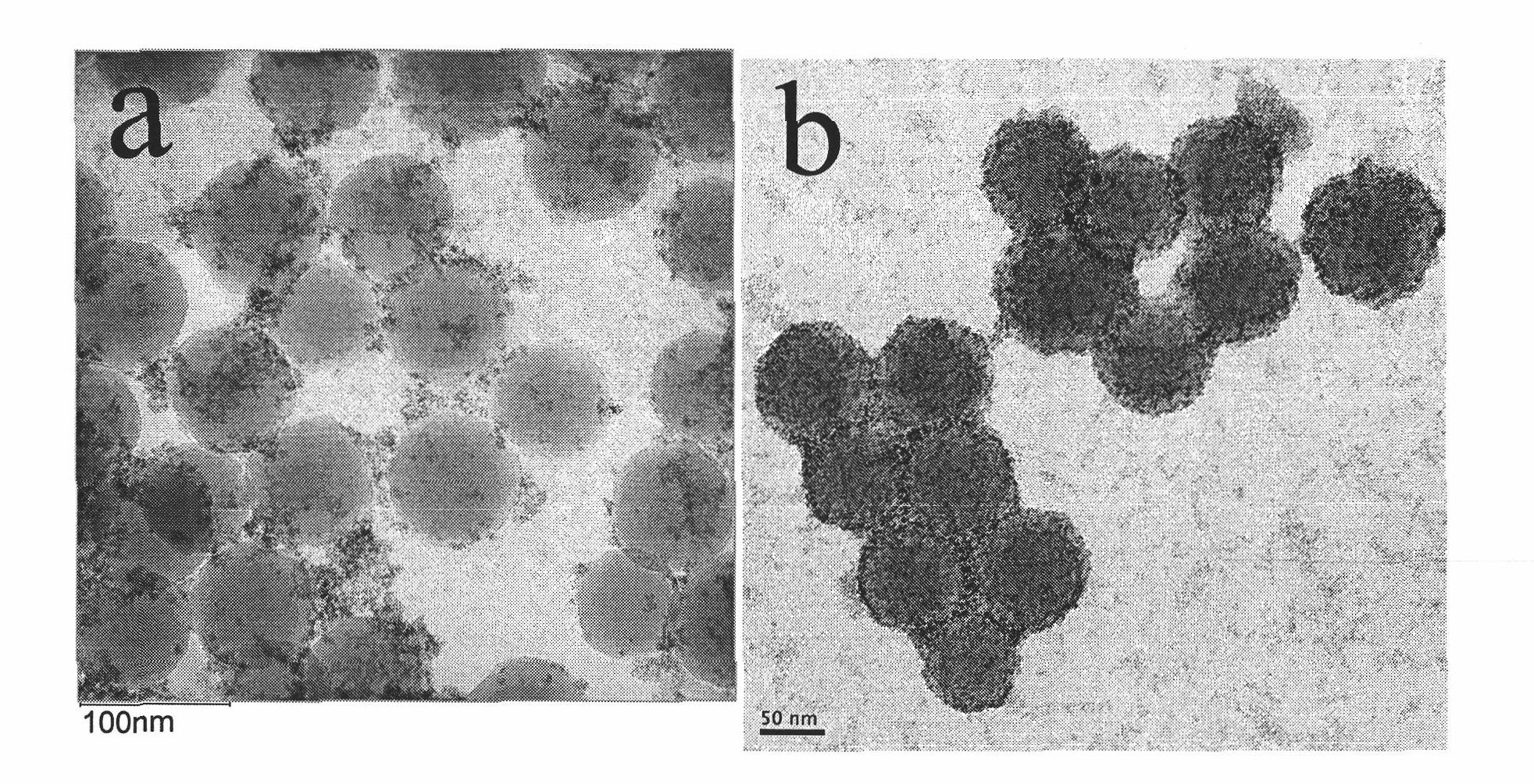

[0059] Take 200g of 10% high-purity silica sol with a particle size of 140nm and a concentration of 200g obtained by crystal growth, add 0.1g of PVP, then heat to 100°C, add 200g of a mixed solution containing 19.12g of ceric ammonium nitrate and 8.37g of urea, After the reaction is completed, age for 2 hours, then perform ultrafiltration, dilute with deionized water after ultrafiltration, and then obtain the primary product of silicon oxide-cerium oxide composite abrasive after ultrafiltration; then put the primary product into water Thermal reaction kettle, crystall...

Embodiment 3

[0072] The preparation method of high-purity silica sol (which contains silica abrasive particles with a particle size of 20nm, and based on the high-purity silica sol abrasive, the weight percentage of silica abrasive particles is 2%) is the same as in Example 1.

[0073] Get 200g particle diameter that is 20nm by crystal growth, concentration is 2% high-purity silica sol, add 0.8gPVP, then be heated to 70 ℃, add the mixed solution that 200g contains the ammoniacal liquor of 0.8g cerium nitrate and 0.8g, then Add 0.1g of hydrogen peroxide, age for 5 hours after completion of the reaction, then carry out ultrafiltration, dilute with deionized water after ultrafiltration, and then after ultrafiltration treatment, the first product of silicon oxide-cerium oxide composite abrasive can be obtained; The initial product was placed in a hydrothermal reaction kettle, and crystallized at 240° C. for 1 hour to finally obtain core-shell composite abrasive particles with a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com