Bend-resistant perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the manufacture of circuits, electrical components, and final products, can solve problems such as poor electrical conductivity, achieve high coverage, large grain size, and slow down the crystallization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

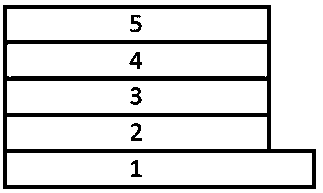

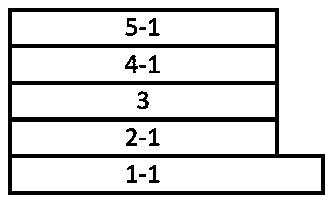

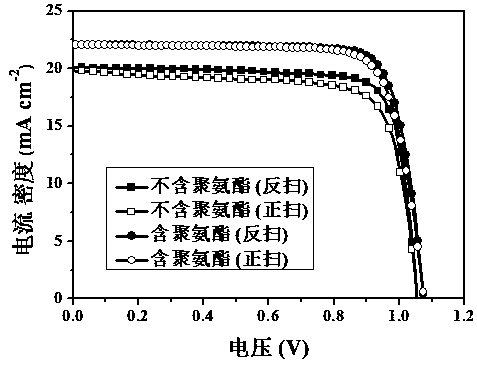

[0042] Example 1. Preparation method of perovskite solar cells.

[0043] (1) After the patterned ITO glass substrate 1 was ultrasonically cleaned with acetone, detergent, deionized water, and isopropanol, it was dried and cleaned in a plasma cleaning machine for 2 to 3 minutes, and calcium oxide was prepared on the substrate. Hole transport layer 2 for titanium oxide solar cells.

[0044] (2) Add polyurethane material (dissolved in DMF at a certain concentration) to CH at a certain mass concentration 3 NH 3 PB 3 Perovskite precursor solution, and stirred at 60°C for 1-2 h to dissolve, mixed evenly and then spin-coated on the hole transport layer to obtain the perovskite active layer 3, the rotation speed is 5500 rpm, time 30 s, in which chlorobenzene was added dropwise at the 7th s of spin coating.

[0045](3) Anneal the coated perovskite active layer sample at 90°C~120°C for 10 min~20 min.

[0046] (4) The electron transport layer material PC 61 BM was dissolved in chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com