Full-body anti-slip ceramic brick and production method thereof

A manufacturing method and technology of ceramic tiles, which are applied in clay products, other household appliances, applications, etc., can solve the problems of using beauty less than natural marble, poor anti-skid performance, etc., to improve suspension performance, reduce surface defects, and reduce waste water discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with accompanying drawing:

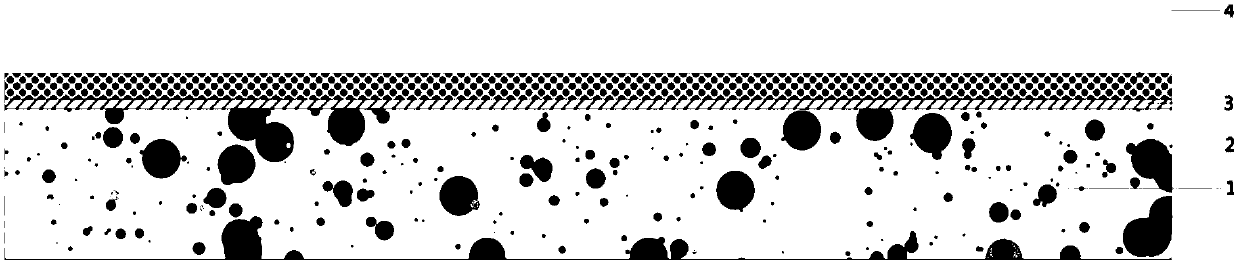

[0048] see figure 1 As shown, the whole body non-slip ceramic tile is decorated with colored speckled body layer 1, large-grained colored speckles 2 mixed in said colored speckled green body layer 1, and patterns covered on the surface of said colored speckled green body layer 1. Layer 3, the dry granular glaze layer 4 covered by the pattern decoration layer 3 constitutes a composite layer ceramic tile; wherein:

[0049]The color speckle green body layer 1 is composed of conventional powder and large-grain powder, the particle diameter of conventional powder is 0.4-0.7 mm, and the particle diameter of large-grain powder is 5-7 mm; the large-grain powder is composed of white, yellow, gray A mixture of black and black, in which white large particles account for 0.3-0.5%, and one of yellow, gray or black large particles accounts for 0.3-0.5%;

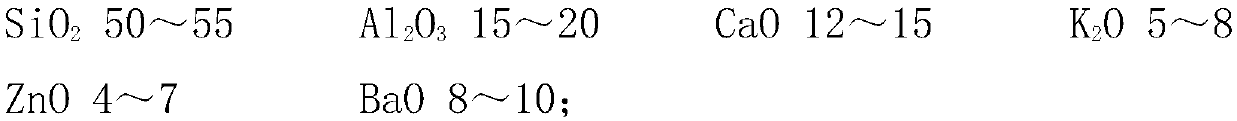

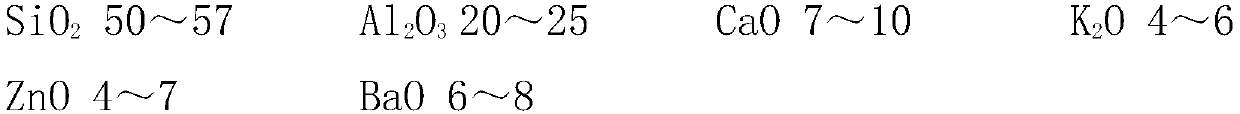

[0050] The raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com