A halogen passivated perovskite quantum dot, a preparation method thereof and a QLED device are provided

A technology of quantum dots and quantum dot solutions, applied in the field of quantum dots, can solve the problems of reduced fluorescence intensity of inorganic perovskite quantum dots, and achieve the effects of improving fluorescence intensity and charge transfer efficiency, effective passivation, and reducing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

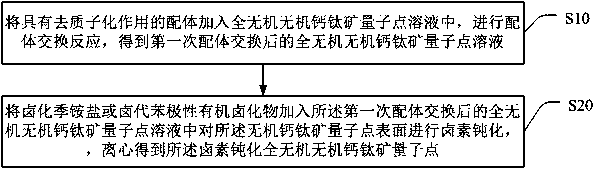

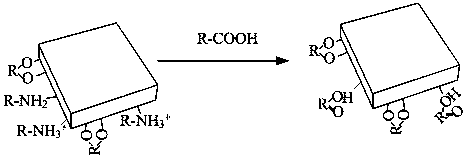

Method used

Image

Examples

Embodiment 1

[0045] The chlorine element passivation CsPbBr of the present embodiment 3 A method for preparing quantum dots, comprising the steps of:

[0046] (1), preparation of cesium oleate Cs(OA) stock solution:

[0047] Weigh 0.814g of cesium carbonate Cs 2 CO 3 Add to a 100ml three-neck flask, add 30ml of octadecene (ODE) and 2.5ml of oleic acid (OA) to the flask;

[0048] Under an inert gas, first exhaust at room temperature for 20 minutes, then heat to 120°C and exhaust for 60 minutes, and finally heat to 160°C to make all the cesium carbonate Cs 2 CO 3 React with oleic acid, then keep the solution temperature at 160°C to avoid solidification of cesium oleate Cs(OA) solution, and prepare cesium oleate Cs(OA) stock solution.

[0049] (2), CsPbBr 3 Preparation of quantum dots:

[0050] Take 50ml of octadecene (ODE), 5ml of oleylamine (OAm) and 0.7g of lead bromide (PbBr 2 ) together into a 100ml three-necked flask, first exhaust at room temperature for 20 minutes under inert ...

Embodiment 2

[0056] The iodine element passivated CsPbBr of the present embodiment 3 A method for preparing quantum dots, comprising the steps of:

[0057] (1), using the method of Example 1 of the present invention to prepare CsPbBr 3 Quantum dot toluene solution;

[0058] (2), CsPbBr passivated by iodine element 3 Preparation of quantum dots:

[0059] Add 50 μl of oleic acid (OA) to the quantum dot toluene solution and stir for 30 min, then add 100 μl of 0.05 mmol iodopentafluorobenzene (IPFB) solution and stir for another 30 min, and finally mix with butanol The solution was centrifuged and precipitated, and then dispersed in toluene to obtain iodine-passivated CsPbBr 3 Quantum dot solution.

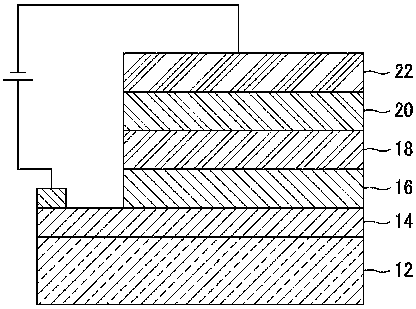

[0060] The QLED device of this embodiment, such as image 3 As shown, it includes an anode 14, a hole transport layer 16, a quantum dot light-emitting layer 18, an electron transport layer 20 and a cathode 22 stacked on the substrate 12 from bottom to top, wherein the quantum dot light-emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com