Quantum dot luminescent layer and preparation method thereof, and quantum dot light-emitting diode (QLED) and preparation method thereof

A quantum dot light-emitting and diode technology, which is used in the manufacture of semiconductor/solid-state devices, electrical components, and electric solid-state devices, etc., can solve the problems of uneven coverage, uneven thickness, and easy peeling of the quantum dot light-emitting layer. Achieve the effect of maintaining interface stability and interface properties and passivating surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

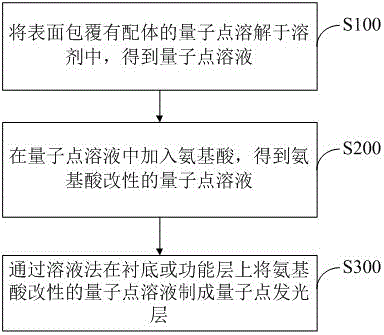

[0061] 1) Preparation of quantum dot solution:

[0062] NH was added to the CdSe / ZnS quantum dot solution coated with mercaptopropionic acid (MPA) ligands at a ratio of 1:0.01 by mass percentage. 2 -(CH 2 ) 2 -COOH, to obtain amino acid modified CdSe / ZnS quantum dot solution.

[0063] 2) Preparation of quantum dot light-emitting diodes:

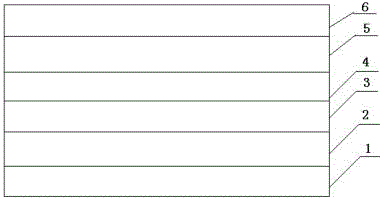

[0064] Spin-coat a layer of PEDOT:PSS thin film on the ITO substrate as the hole injection layer;

[0065] On the PEDOT:PSS layer, spin-coat a layer of PVK film as a hole transport layer;

[0066] Then, the amino acid-modified quantum dot solution prepared in the above 1) was spin-coated on the PVK layer to obtain a dense and smooth CdSe / ZnS quantum dot light-emitting layer modified by amino acid cross-linking and tightly anchored on the PVK layer ;

[0067] Next, spin-coat a layer of ZnO film on the CdSe / ZnS quantum dot light-emitting layer as an electron transport layer;

[0068] Finally, a layer of Al is vapor-deposited on the ZnO l...

Embodiment 2

[0070] 1) Preparation of quantum dot solution:

[0071] NH was added to the CdSe / ZnS quantum dot solution coated with mercaptopropionic acid (MPA) ligands at a ratio of 1:0.05 by mass percentage. 2 -(CH 2 ) 4 -COOH, to obtain amino acid modified CdSe / ZnS quantum dot solution.

[0072] 2) Preparation of quantum dot light-emitting diodes:

[0073] Spin-coat a layer of PEDOT:PSS thin film on the ITO substrate as the hole injection layer;

[0074] Spin-coat a layer of TFB film on the PEDOT:PSS layer as a hole transport layer;

[0075] Then, the amino acid-modified quantum dot solution prepared in the above 1) was spin-coated on the TFB layer to obtain a dense and smooth CdSe / ZnS quantum dot light-emitting layer modified by amino acid cross-linking and tightly anchored on the TFB layer ;

[0076] Next, spin-coat a layer of ZnO film on the CdSe / ZnS quantum dot light-emitting layer as an electron transport layer;

[0077] Finally, a layer of Al is vapor-deposited on the ZnO la...

Embodiment 3

[0079] 1) Preparation of quantum dot solution:

[0080] NH was added to the CdSe / ZnS quantum dot solution coated with thioglycolic acid (TGA) ligands at a ratio of 1:0.02 by mass percentage. 2 -(CH 2 ) 11 -COOH, to obtain amino acid modified CdSe / ZnS quantum dot solution.

[0081] 2) Preparation of quantum dot light-emitting diodes:

[0082] Spin-coat a layer of PEDOT:PSS thin film on the ITO substrate as the hole injection layer;

[0083] Spin-coat a layer of TFB film on the PEDOT:PSS layer as a hole transport layer;

[0084] Then, the amino acid-modified quantum dot solution prepared in the above 1) was spin-coated on the TFB layer to obtain a dense and smooth CdSe / ZnS quantum dot light-emitting layer modified by amino acid cross-linking and tightly anchored on the TFB layer ;

[0085] Next, spin-coat a layer of ZnO film on the CdSe / ZnS quantum dot light-emitting layer as an electron transport layer;

[0086] Finally, a layer of Al is vapor-deposited on the ZnO layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com