Sheet metal multi-point progressive forming device

A progressive forming and multi-point technology, applied in the field of sheet metal stamping, can solve the problems of high requirements, large suspended area of sheet metal, and high cost, and achieve the effect of optimal forming path, uniform strain distribution, and improved forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

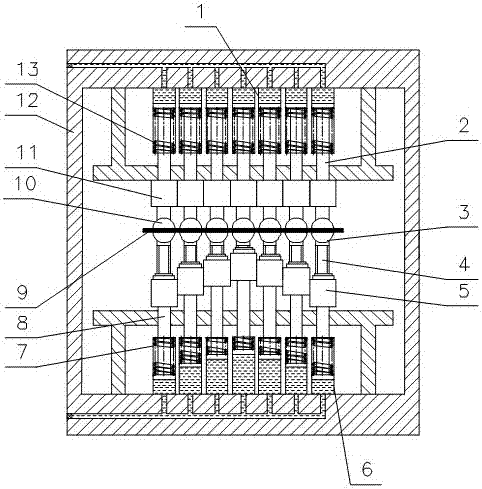

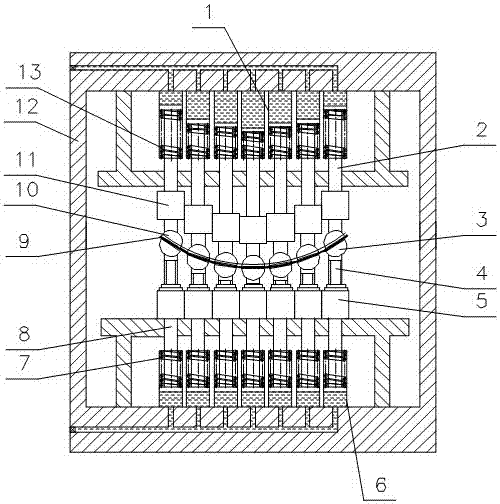

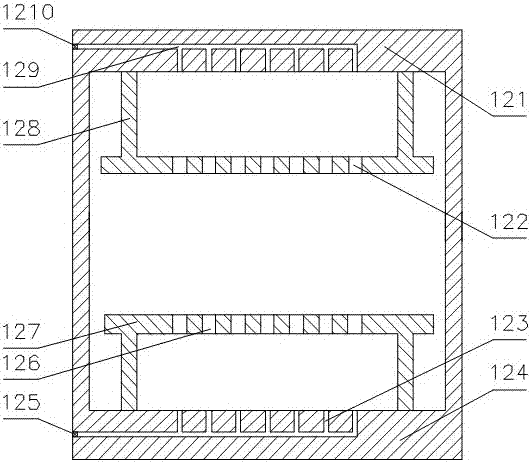

[0019] From figure 1 , figure 2 , image 3 It can be seen from the figure that a multi-point progressive forming device for sheet materials includes a mold base 12, a number of driving and pressing units, a number of shape-adjusting support units, and the like. Described several driving pressurization units are installed on the top plate 121 of formwork 12, and each drive pressurization unit is made up of upper pressing head 10, driving basic body 11, spring 7, piston 8, driving hydraulic cylinder 1, and described upper pressing The head 10 is movably installed on the bottom of the driving basic body 11 , the piston 8 is connected with the driving basic body 11 , and the spring 8 is installed in the driving hydraulic cylinder 1 to form an upward supporting force on the piston 2 . The driving hydraulic cylinder 1 is fixed on the formwork top plate 121 and connected with the hydraulic control system. The several shape-adjusting support units are installed on the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com