Hydraulic multi-head fixed rail echelon backing-off cutting cylindrical gear one-step molding equipment

A technology of cylindrical gears and forming equipment, which is applied in the direction of mechanical equipment, belts/chains/gears, gear teeth, etc., can solve labor-consuming and time-consuming problems, achieve the effects of improving the precision of finished products, eliminating tedious labor, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

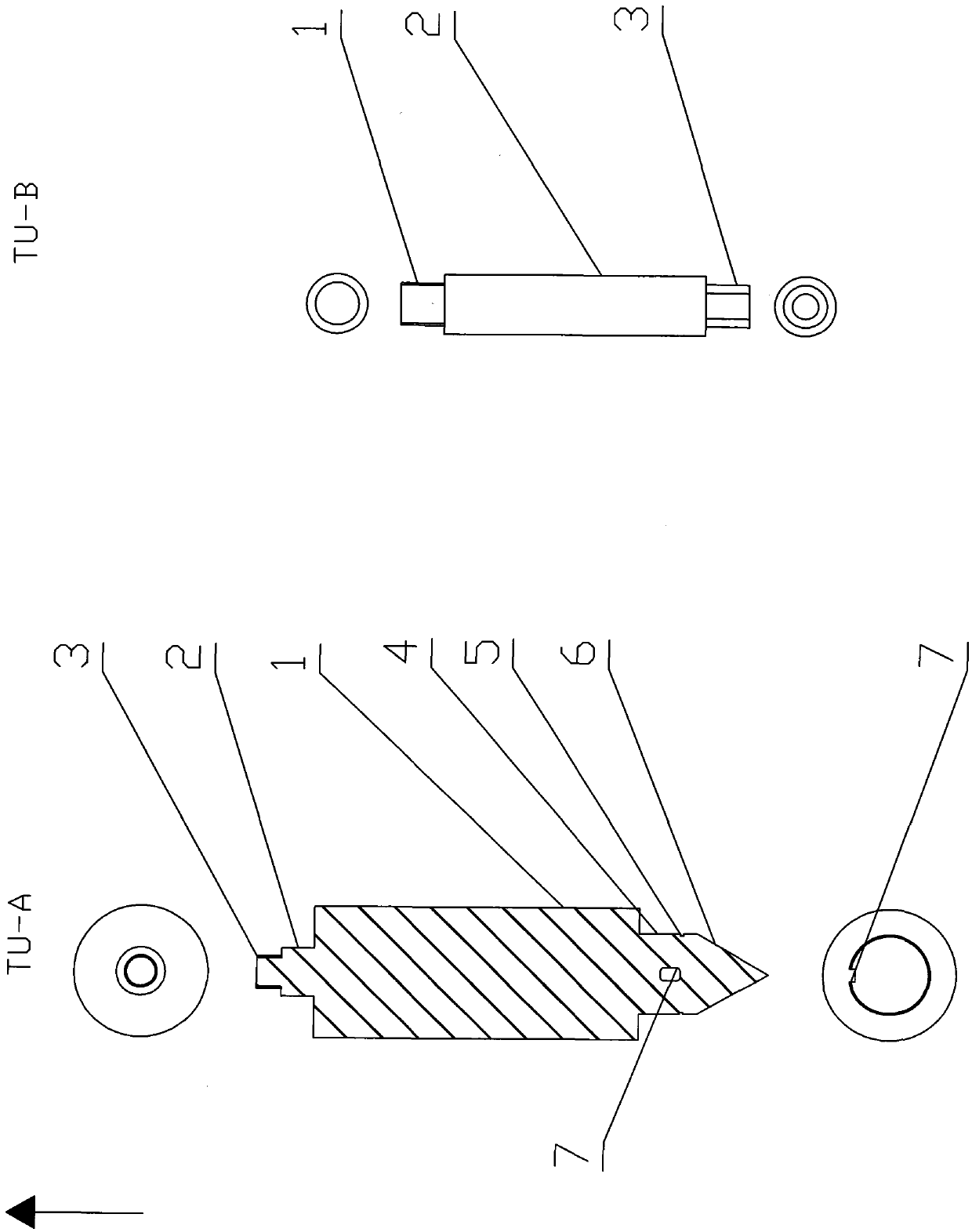

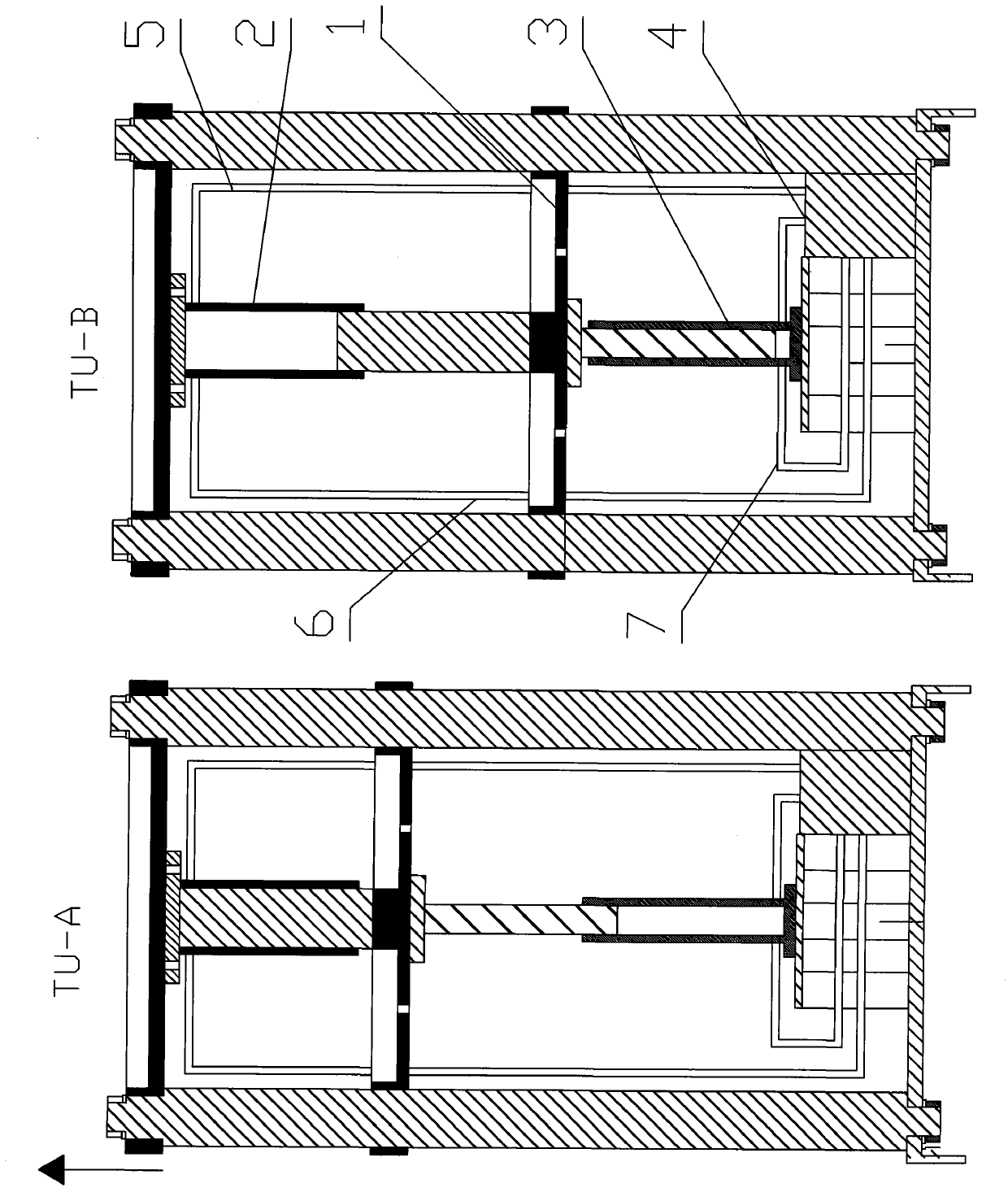

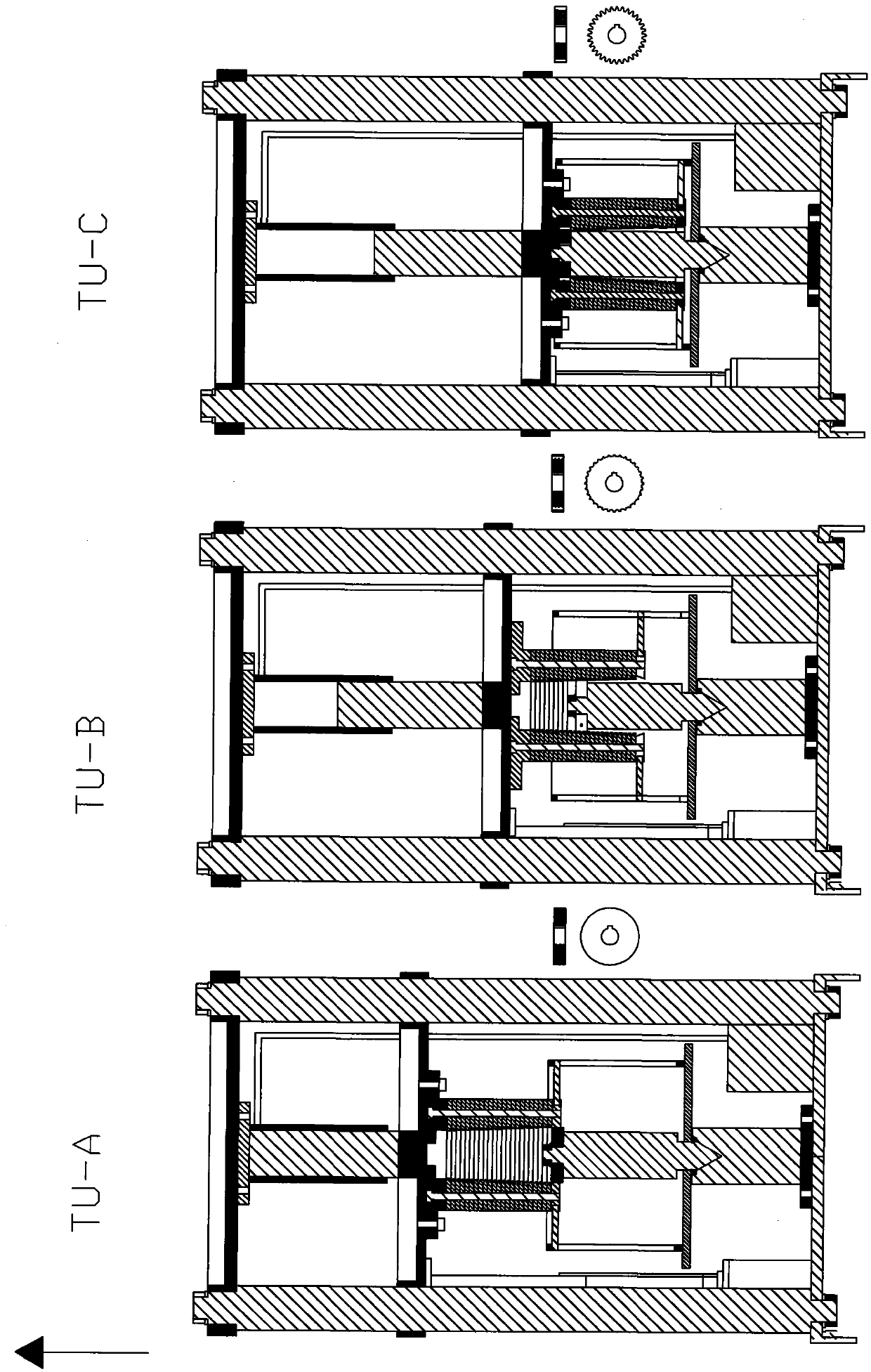

[0051] The specific implementation method first introduces the machining process of spur gears, such as Figure 21 As shown in (TU-A), the starting equipment lifts the lifting plate, puts the turned gear blank into the workpiece boss of the pressure-bearing rotating shaft of the pressure-bearing rotating system, adds pads and installs lock nuts to fix it, and the gear blank at this time is Like a perforated discus with neat edges, its shape is a hollow cylinder with an outer diameter of Φ102mm, a thickness of 20mm, and a hole diameter of Φ35mm. Start the hydraulic pump and open the pressurizing valve to pressurize the hydraulic cylinder. The hydraulic column is pushed out to push the lifting plate to move downward. Figure 21 As shown in (TU-B), the ring-shaped evenly distributed cutter head on the first shoveling piece of the multi-head rail-fixed stepped shoveling die gradually cuts the workpiece, and cuts out 32 uniformly distributed shallow grooves with a depth of 0.30mm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com