Roller with flexibly adjustable roller type curves

A flexible technology for adjusting rolls, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of inability to carry out quantitative temperature adjustment, difficult to solve the temperature coupling relationship, and no temperature sensor at the heat source, etc., to reach the electric heating temperature Quick response, easy construction, compensation for roll wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

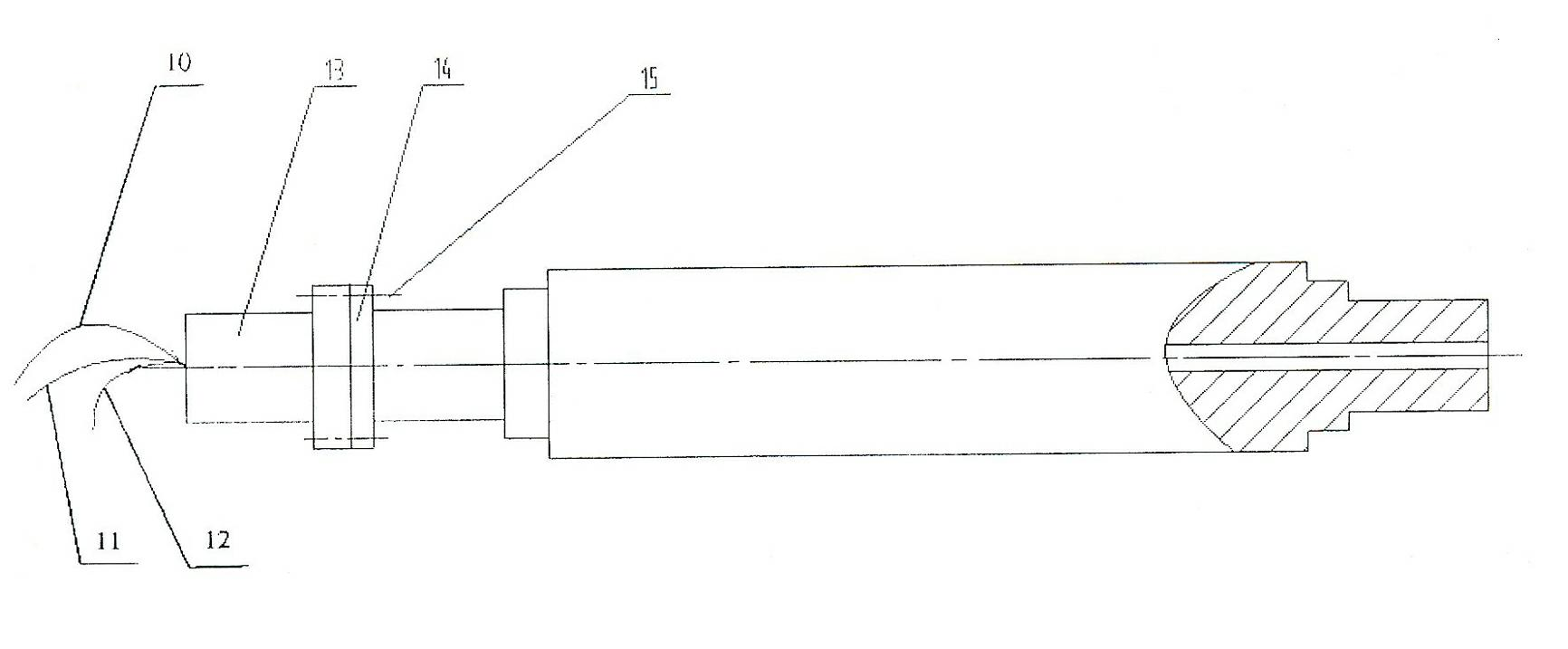

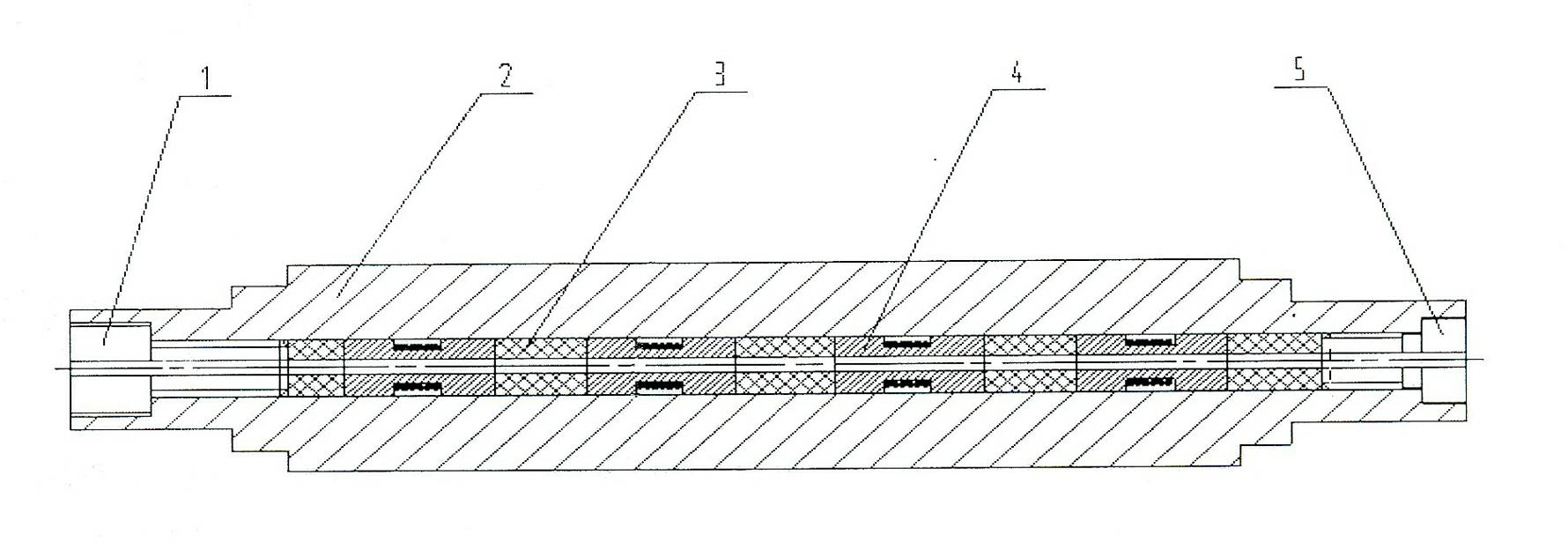

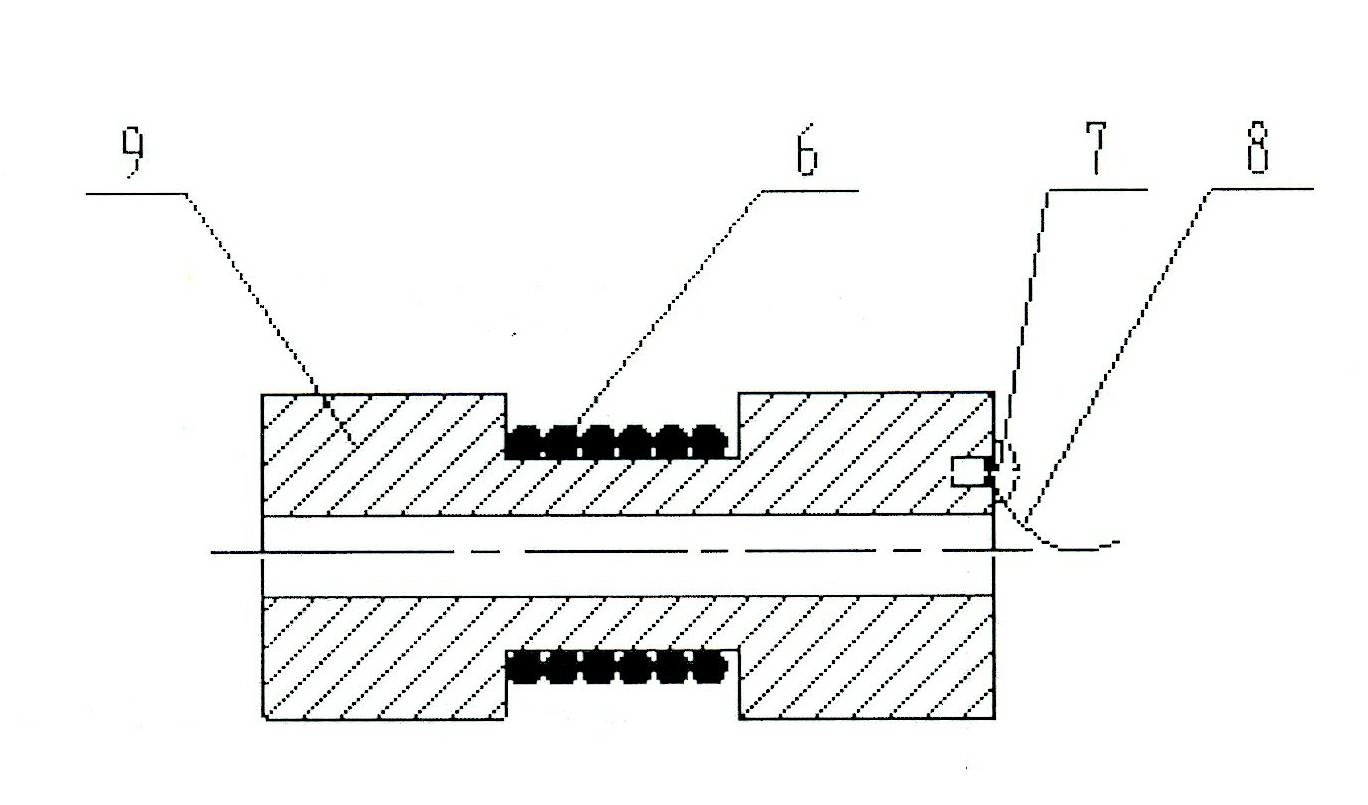

[0034] The structure of a roll that can flexibly adjust the roll profile curve of this embodiment is as follows: figure 1 and figure 2 As shown, it includes a roll body 2 with a through hole or a stepped concentric hole, a slip ring component 13, a connecting flange 14, bolts 15, a temperature detection and control module, a power supply, k groups of internal expansion driving force components 4 and k ±1 set of adiabatic spacer rings 3, where k is a natural number. In this embodiment, the roll body 2 has a through hole, and the electric thermal expansion rod 9 and the roll body 2 maintain an interference fit.

[0035] The k groups of internal expansion driving force components 4 and k±1 groups of heat insulating distance rings 3 are installed in the through-hole of the roll body 2 at intervals; in this embodiment, static fit is used inside the through-hole of the roll body 2 The internal expansion driving force part 4 is installed in the same way, and multiple sets of heat-...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1. The difference between this embodiment and Embodiment 1 is that the electric thermal expansion rod 9 is an end heating (or spiral heating) electric thermal expansion rod, and its structure is as follows Figure 4 As shown, the electrothermal expansion rod 9 is cylindrical in shape with a thick middle and thin ends, and the electrothermal carrier fluid 6 is arranged at the thin ends of the electrothermal expansion rod 9 .

Embodiment 3

[0055] This embodiment is basically the same as Embodiment 1. The difference between this embodiment and Embodiment 1 is that the electric thermal expansion rod 9 is a spiral columnar heating (or core heating) electric thermal expansion rod, and its structure is as follows Figure 5 As shown, the electric thermal expansion rod 9 is a stud or an interference fit casing with spiral grooves distributed on the surface, and the electric heat transfer fluid 6 is arranged in the spiral groove.

[0056] As can be seen from the above examples, the present invention has the following beneficial effects:

[0057] (1) In the present invention, by heating the electric thermal expansion rod that is interference-fitted in the through-hole of the roll body, the electric thermal expansion rod generates internal expansion driving force, and the roll profile curve is pre-controlled and online according to the roll profile control requirements. Adjustment, and through temperature detection and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com