Automatic tube drawing device of doffer

A doffing machine and bobbin technology, which is applied in textiles and papermaking, can solve problems such as damage and achieve the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

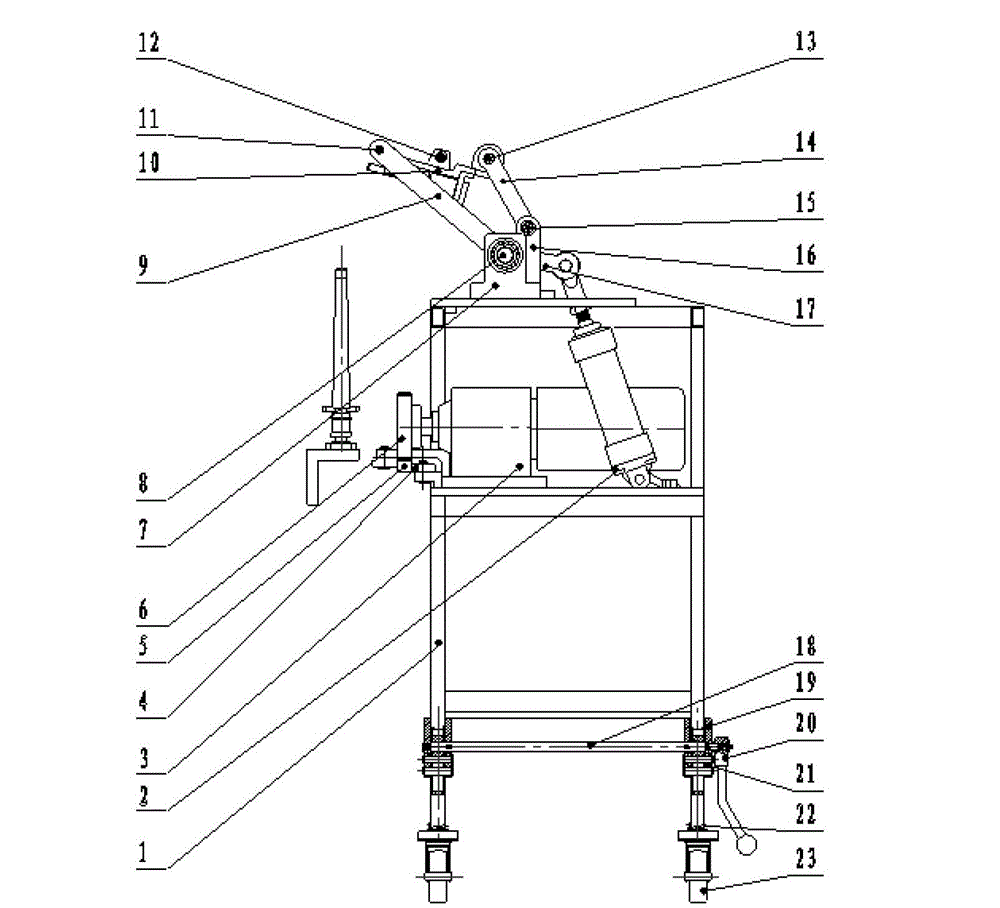

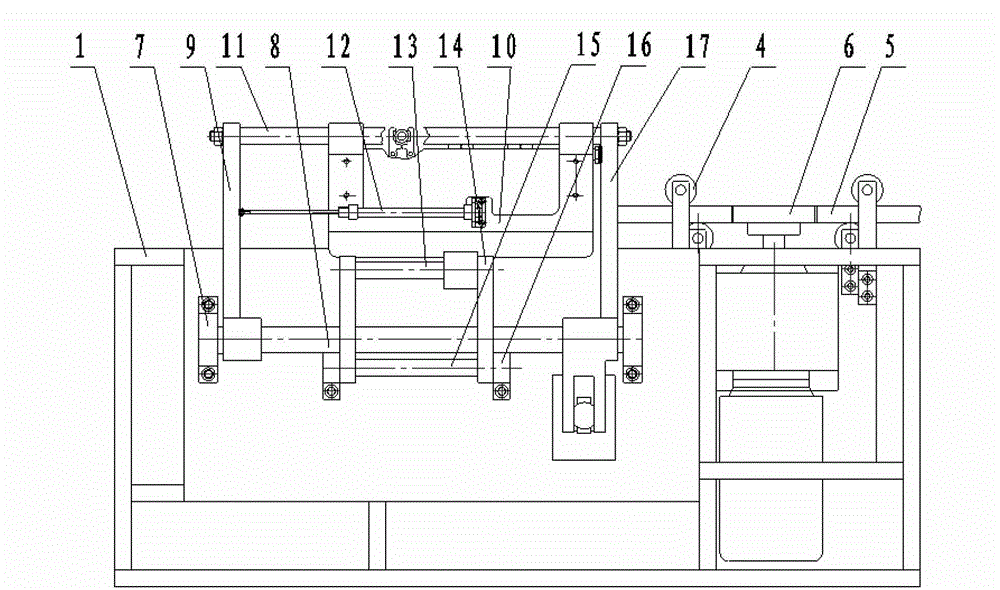

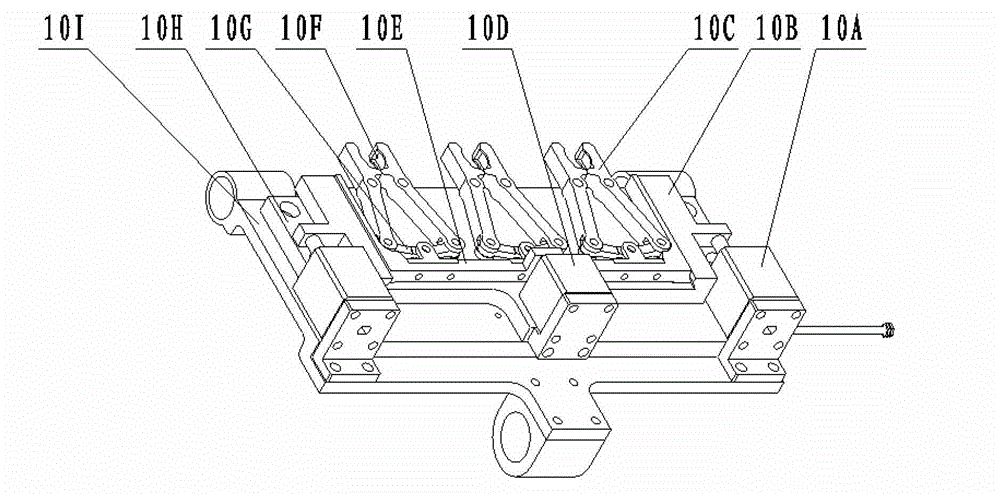

[0014]The main structure in this embodiment includes a frame 1, a main cylinder assembly 2, a reduction motor 3, a guide wheel 4, a rack 5, a gear 6, an active rocker bearing seat 7, an active shaft 8, a front active rocker 9, yarn Pipe clamping device 10, driving rocker guide shaft 11, reset cylinder assembly 12, driven rocker guide shaft 13, driven rocker 14, driven rocker pin 15, driven rocker bracket 16, rear active Rocker 17, rotating shaft 18 for handle, eccentric wheel 19, handle 20, slider 21, spring 22 and universal caster assembly 23; main cylinder assembly 2 and deceleration motor 3 are respectively connected to steel with four M8 bolts On the frame 1 made by welding the square tube and the steel plate, the guide wheel 4 is fixed on the bracket with a steel pin, the bracket for installing the guide wheel 4 is fixed on the frame 1 with M8 bolts, and the steel gear 6 is connected by a key It is connected with the motor shaft and meshed with the steel rack 5 fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com