Optimal design method of low-wear high-speed train wheel profile

A high-speed train, optimized design technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as lack of optimization of wheel rims

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

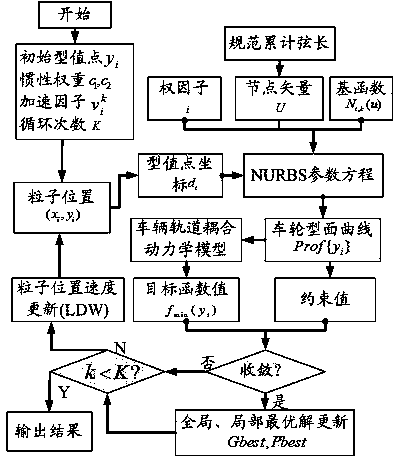

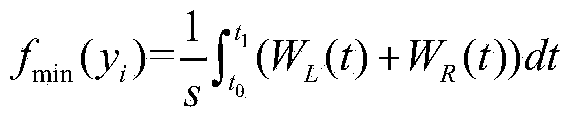

Method used

Image

Examples

Embodiment Construction

[0061] The specific embodiment of the present invention is as follows;

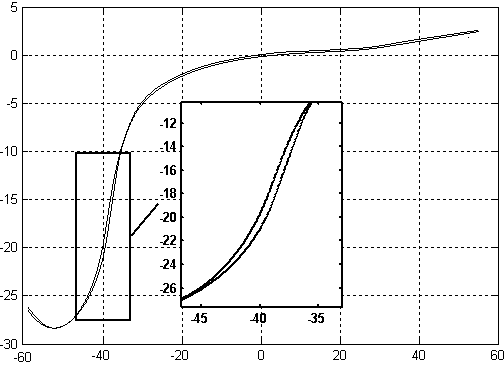

[0062] In this embodiment, the total length of the curve within x=[1,120]mm of the high-speed train wheel profile is divided into 14, 19, and 24 segments of equal arc length, and N=15, 20, and 25 discrete coordinate points are obtained, which are set as type value point d i (i=0,1...,n), establish a parametric design method for NURBS curves, and calculate the correlation coefficients between the fitting curves and CN curves in the three cases are 0.83, 0.93, 0.97, and select 19 after comparative analysis The segment segmentation method takes N=20 value points to satisfy the good description of the shape of the wheel surface, and obtains the NURBS parametric curve and the abscissa positions of the value points, as shown in Table 1.

[0063] Table 1 The coordinate points of the arc length division of 19 equal parts of the high-speed train wheel profile curve

[0064]

[0065] shown. With its correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com