Composite resin concrete steel bridge deck pavement structure and construction method thereof

A resin concrete and composite resin technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of increased surface stress of pavement, fatigue cracking of steel structures, insufficient stiffness of steel bridge decks, etc., to increase the friction coefficient, reduce Stress amplitude, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

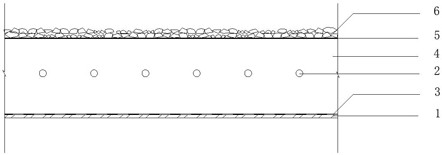

[0079] see figure 1 A steel bridge deck pavement structure provided in this embodiment comprises from bottom to top: a steel bridge deck 1, a resin waterproof adhesive layer 3, a resin concrete layer 4, a fiber material layer 5, and a gravel wear layer 6; Wherein, the reinforcement layer 2 is laid in the resin concrete layer 4 .

[0080] The reinforcing layer 2 is a steel mesh sheet, and / or, fiber material; laid in the middle of the resin concrete layer, it can be a single layer or a multi-layer setting. In a specific embodiment, the fiber material can be fiber cloth or It is fiber mesh, preferably glass fiber cloth; steel mesh and fiber material can be used in combination.

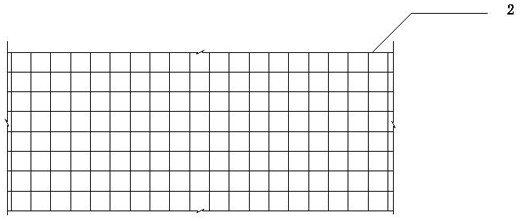

[0081] see figure 2 , the steel mesh is obtained by vertically equidistant distribution of longitudinal and horizontal steel bars, and the junction is usually fixed by binding; according to different road surface requirements, the thickness of the resin concrete layer 4, and other different actual cond...

no. 2 example

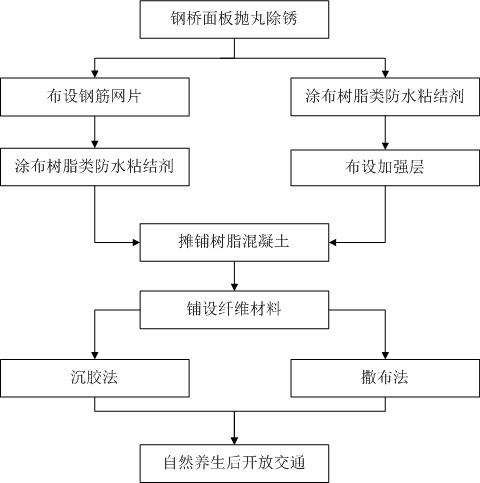

[0088] This embodiment provides a construction method for a composite resin concrete steel bridge deck pavement structure, comprising the following steps:

[0089] S10: Perform shot blasting and derusting treatment on the steel bridge deck to make the surface roughness reach 50 microns to 100 microns.

[0090] S20: Arrange reinforcement mesh sheets above the steel bridge deck, and use pads to control its height;

[0091] Coating the resin waterproof adhesive on the surface of the steel bridge deck needs to be completed within 2 to 4 hours after the steel bridge deck is shot blasted to form a resin waterproof adhesive layer; the amount of the resin waterproof adhesive is 0.1 kg / m2 to 1.0 kg / m2.

[0092] S30: paving resin concrete on top of the resin waterproof adhesive layer, and wrapping the reinforcement mesh to form a resin concrete layer; wherein, the resin concrete includes aggregates and binders.

[0093] Preferably, steel fibers are added to the resin concrete for rein...

no. 3 example

[0104] In this embodiment, the beneficial effect of the technical solution provided by the present invention will be demonstrated in combination with specific experimental data.

[0105] Specimen 1 includes the following structure from bottom to top: steel bridge deck, resin waterproof bonding layer, and resin concrete layer.

[0106] Specimen 2 includes the following structure from bottom to top: steel bridge deck, resin waterproof adhesive layer, and resin concrete layer; wherein, the resin concrete layer is reinforced with steel fibers.

[0107] Specimen 3 includes the following structure from bottom to top: steel bridge deck, resin waterproof adhesive layer, and resin concrete layer; among them, steel mesh is added in the middle of the resin concrete layer.

[0108] Specimen 4 includes the following structure from bottom to top: steel bridge deck, resin waterproof bonding layer, resin concrete layer, and fiber material layer.

[0109] For the construction methods of test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com