Preparation method of aluminum-doped zinc oxide transparent conductive film

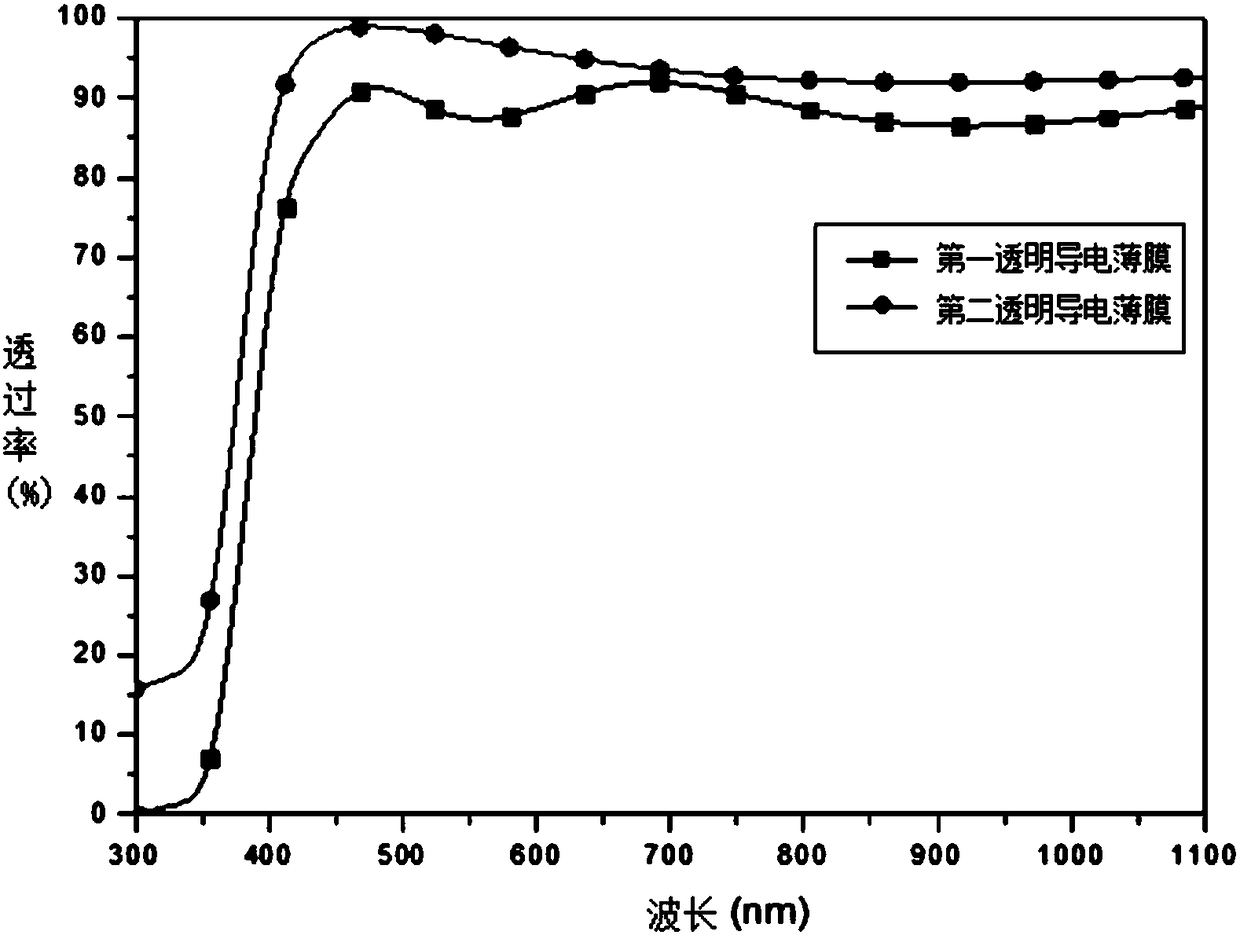

A transparent conductive film, aluminum-doped zinc oxide technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as adverse reactions, device loss, uneven film quality, etc., to achieve high transparency , Excellent photoelectric performance, the effect of reducing sheet resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below according to specific embodiments and accompanying drawings.

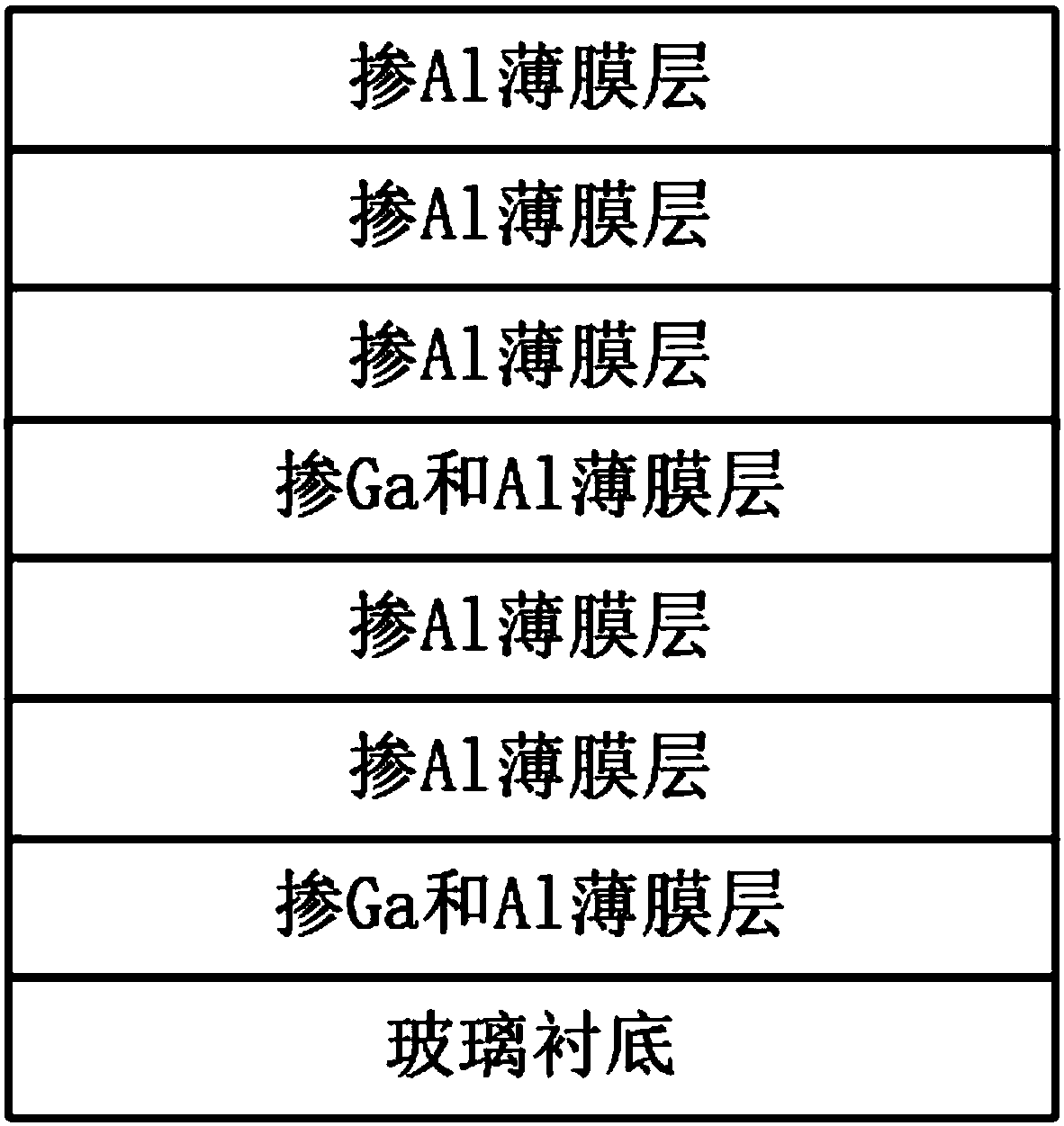

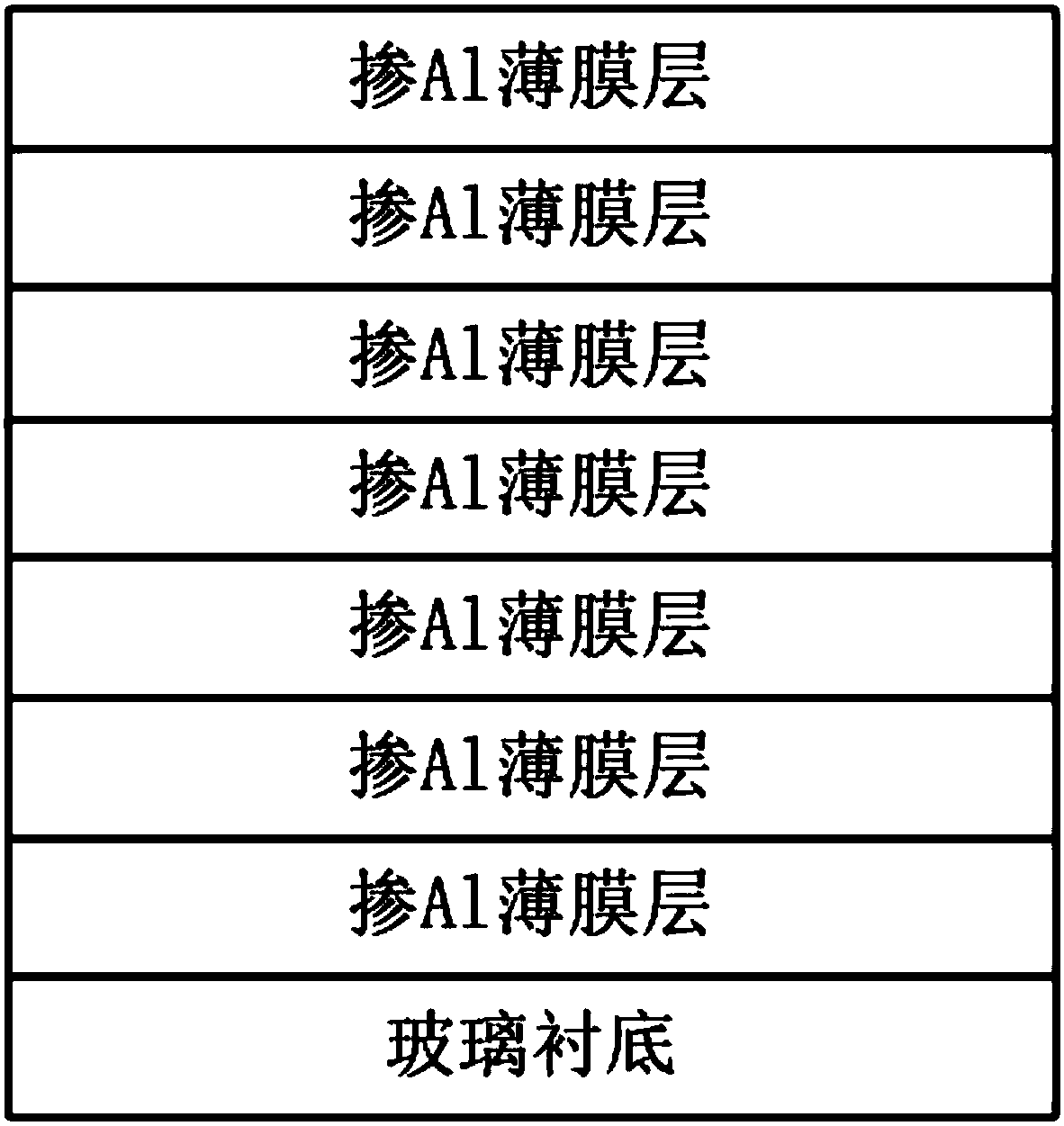

[0037] A method for preparing an aluminum-doped zinc oxide transparent conductive film, comprising the steps of:

[0038] Zinc acetate dihydrate is used as zinc source, aluminum nitrate nonahydrate is used as aluminum source, gallium nitrate nonahydrate is used as gallium source, ethylene glycol methyl ether is used as solvent, and monoethanolamine is used as stabilizer;

[0039] The substrate is specifically a glass substrate, which is ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 15 minutes before use, and the cleaned glass substrate is dried with nitrogen, and placed in a constant temperature drying oven for use;

[0040] S1. Configure the sol: Weigh 5.4875g of zinc acetate dihydrate and add it to 50mL of ethylene glycol methyl ether, stir until dissolved at a temperature of about 30°C, then add 1.5ml of ethanolamine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com