Designing method for realizing equal load-carrying of tension-loaded butt joint with central crack on welding line, and application of K factor

A technology for butt joints and central cracks, which is applied in special data processing applications, calculations, instruments, etc., and can solve problems such as low-stress brittle fracture accidents and low bearing capacity of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

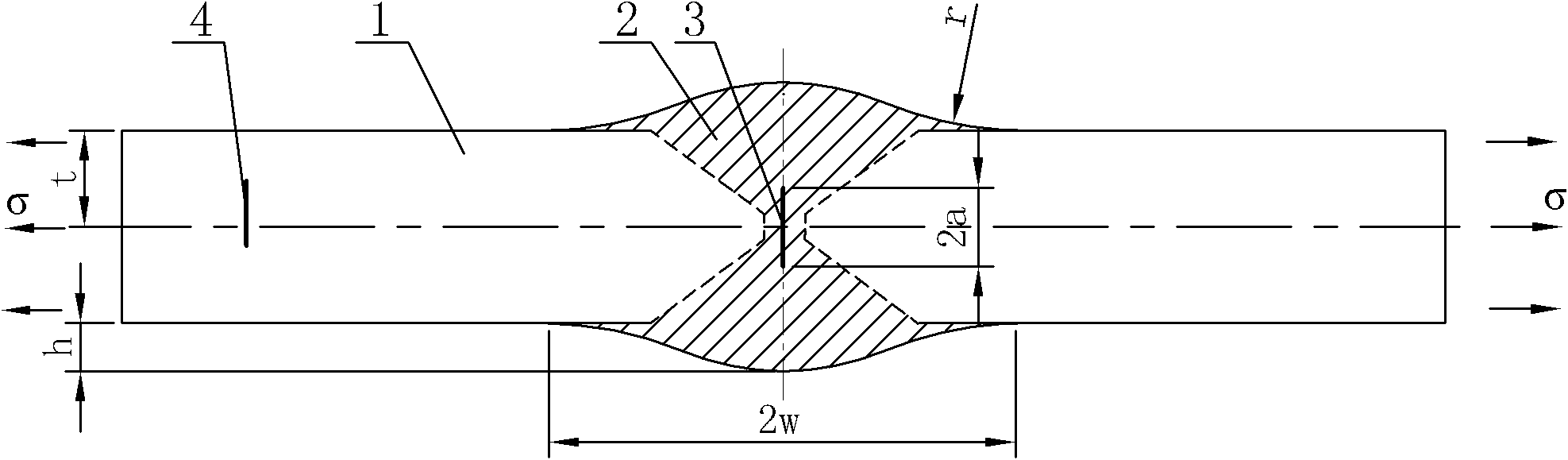

[0090] Specific implementation mode one: see figure 1 , the design method of the butt joint with a central crack in the weld to achieve equal load bearing is based on the ratio of the stress intensity factor of the weld to the base metal and the fracture toughness of the weld to the base metal. equal bearing ratio and reduce the stress concentration factor of the weld toe as much as possible to achieve equal load; according to the bearing characteristics, in order to ensure the fatigue strength of the butt joint, the shape of the weld seam of the butt joint is determined as figure 1 The shown weld shape between the reinforcement and the base metal adopts a simple arc curve transition; the design method of the butt joint is:

[0091] Step 1. Determine the equal load-carrying condition that satisfies the condition that both the weld zone and the base metal have cracks:

[0092] K I w K I ...

specific Embodiment approach 2

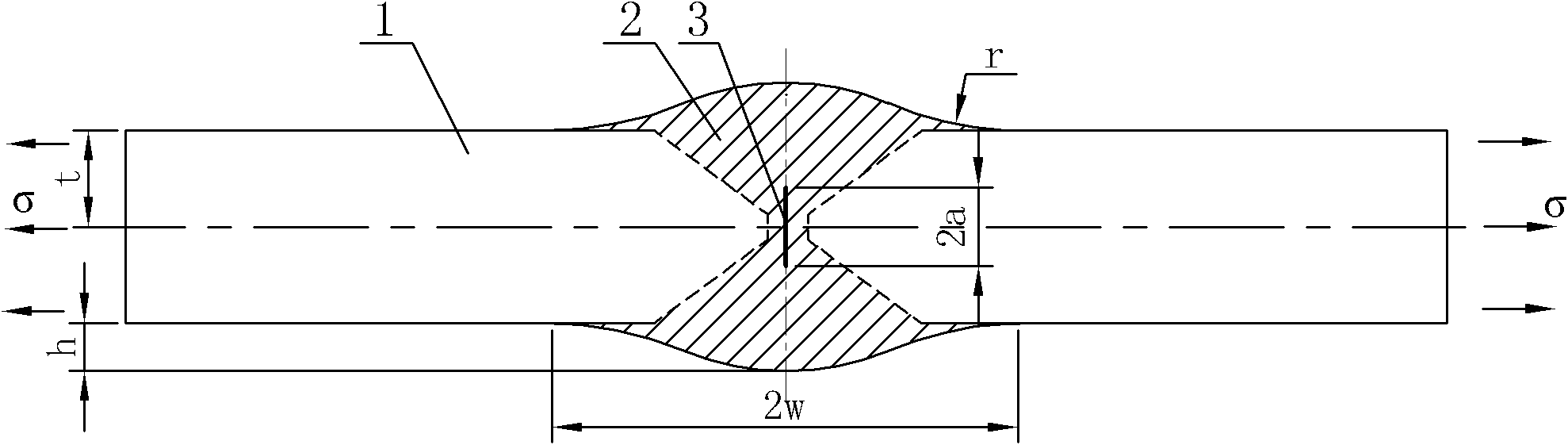

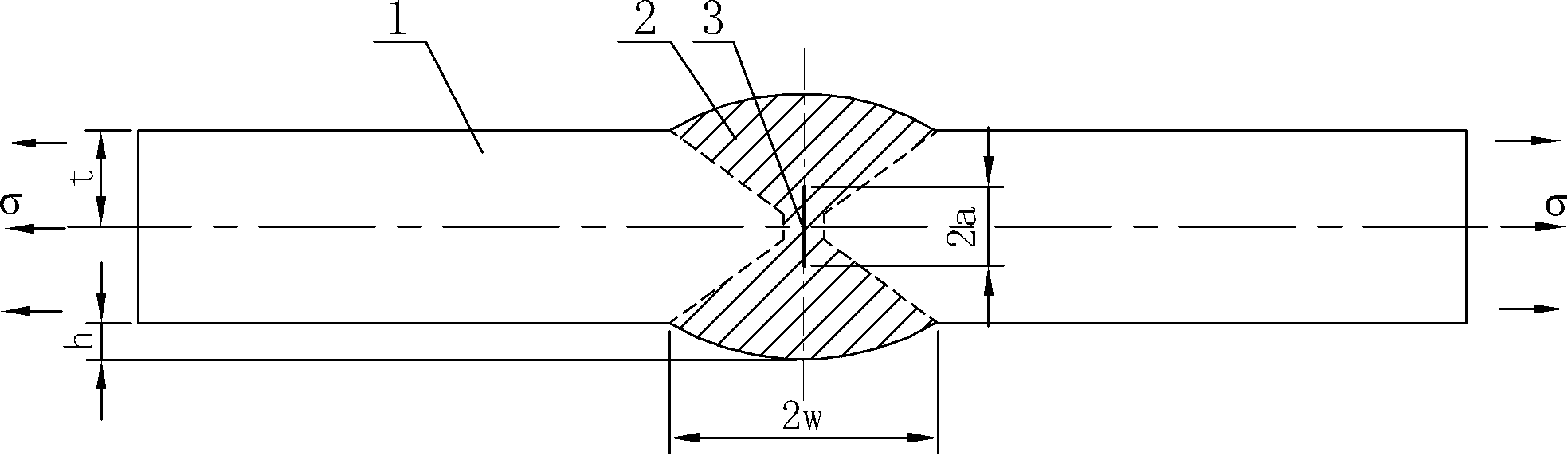

[0110] Specific implementation mode two: see figure 2 In this embodiment, the design method for butt joints with central cracks in the weld to achieve equal load bearing is based on the fact that the critical stress of crack instability and propagation in the weld is equal to the tensile strength of the base metal, and the weld toe stress should be reduced as much as possible. Concentration factor to achieve equal load; according to the load characteristics, in order to ensure the fatigue strength of the butt joint, the shape of the weld seam of the butt joint is determined as follows figure 2 The shown weld shape between the reinforcement and the base metal adopts a simple arc curve transition; the design method of the butt joint is:

[0111] Step 1. Determine the equal load-carrying conditions when there are cracks in the weld zone and the base metal has no defects:

[0112] σ c w = σ b ...

specific Embodiment approach 3

[0131] Specific implementation mode three: see figure 1 , in the method described in this embodiment, the cracks on the base metal are located at any position other than the total width of the capping weld bead. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com