Large-travel flexible rotary hinge based on four-link mechanisms

A four-bar mechanism, large stroke technology, applied to rotating parts, mechanical equipment, bearings and other directions that resist centrifugal force, can solve problems such as small rotation angle and large strain, reduce stress and strain, small center drift, improve stroke and use effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below.

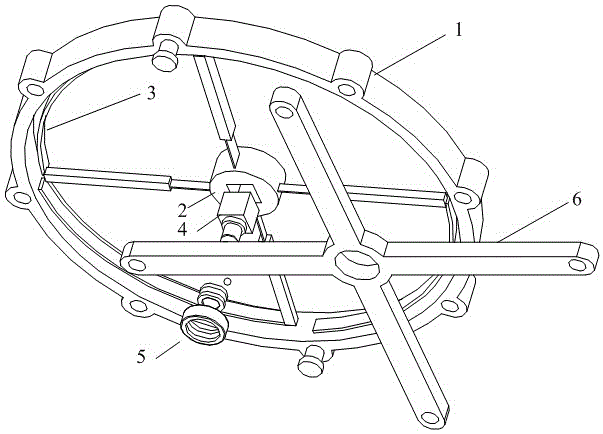

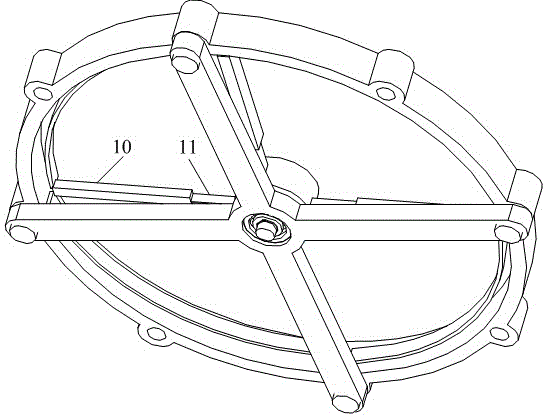

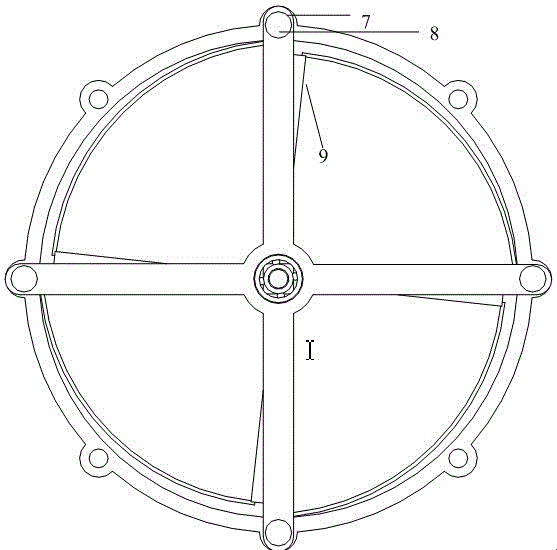

[0027] Implementing the above-mentioned invention provides a large-stroke flexible rotary hinge based on a four-bar mechanism. The flexible rotary hinge is based on a four-bar mechanism. The four-bar mechanism is used as a motion transmission and energy storage module. Taking the crank-rocker mechanism in the above as an example, the rocker is replaced by a flexible rod, and the flexible rocker is used to store energy, and the crank is replaced by the inner ring, so as to realize the rotational movement of a large rotation angle; during the movement of the mechanism, the flexible The flexible rod of the hinge has a certain deformation, stores energy, locks the mechanism, releases the locked part, and rotates the flexible rod in the hinge to realize the reverse movement of the mechanism; the flexible hinge based on the four-bar mechanism includes the outer ring and the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com