Reinforcing method of orthotropic steel box girder bridge deck slab

An orthotropic, steel box girder technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the inability to effectively solve the problem of orthotropic rigid box girder deck, and cannot guarantee the synergy of the upper and lower steel plates , unfavorable bridge facilities and other problems, to improve driving comfort and braking, reduce the risk of cracking, and ensure the effect of synergistic force bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

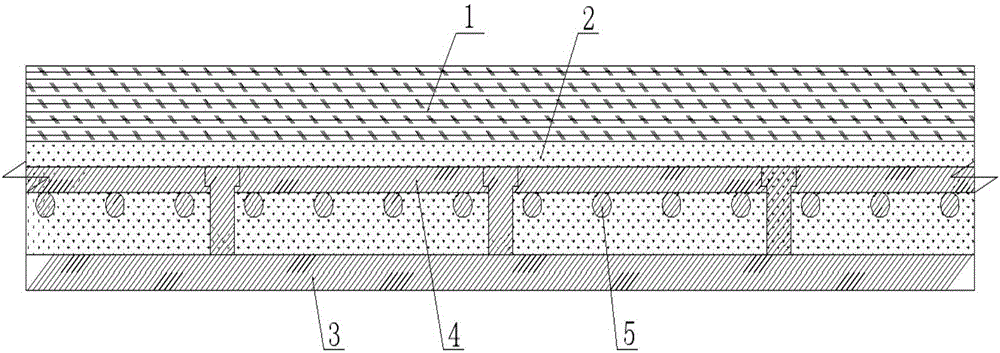

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0030] A method for strengthening an orthotropic steel box girder bridge deck is characterized in that the operation steps are as follows:

[0031] 1) Rust removal: Sandblasting and rust removal of the orthotropic steel box girder deck 3 steel plate;

[0032] 2) Steel box girder roof inspection: inspect the orthotropic slab roof, and reinforce the cracked parts;

[0033] 3) Spray anti-corrosion layer: evenly spray anti-corrosion layer on the orthotropic steel box girder bridge deck after derusting treatment;

[0034] 4) Welding of shear studs: Locate and mark the welding position of the shear studs on the orthotropic steel box girder bridge deck, and then perform welding of the shear studs. After the welding is completed, the damaged anti-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com