Rear drive transmission shaft supporting piece of integrated bidirectionally-vulcanized structure and machining method thereof

A processing method and transmission shaft technology, applied to vehicle components, control devices, transportation and packaging, etc., can solve the problems of small pull-out force, easy to pull and crack, manual work and other problems in bearing assembly, so as to improve axial movement displacement and avoid The problem of assembly misalignment and the effect of small rubber stress and strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described below in conjunction with specific embodiments.

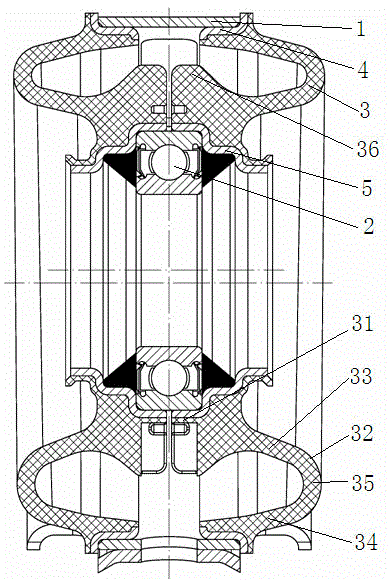

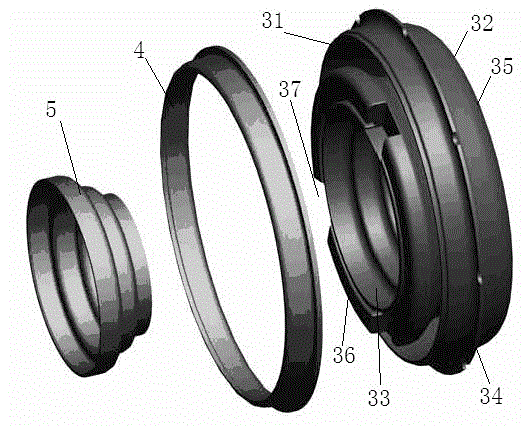

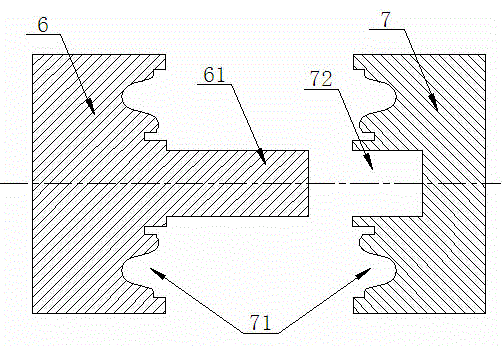

[0026] Such as Figure 1 to Figure 2 As shown, it is a structural schematic diagram of the rear drive drive shaft support and its processing method of the bidirectional vulcanized integrated structure according to the present invention. The rear drive transmission shaft support with bidirectional vulcanization integrated structure and its processing method according to the present invention include: an annular intermediate support mounting bracket 1, and an intermediate support bearing 2 arranged on the radial inner side of the intermediate support mounting bracket 1 An intermediate support main spring 3 is arranged between the intermediate support bearing 2 and the intermediate support mounting bracket 1, and the intermediate support main springs 3 are two symmetrically arranged in the same shape, and the intermediate support main spring 3 It is a spiral structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com