Split type liquid rubber composite joint with low diameter-axial ratio

A liquid rubber, split type technology, applied in the field of rail transit, can solve the problems of small ratio of radial stiffness to axial stiffness, difficulty in realizing the stiffness of liquid rubber composite joints, and reducing the radial stiffness of liquid rubber composite joints, etc. Achieve the effect of reducing the spacing, conducive to fatigue resistance and improving axial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

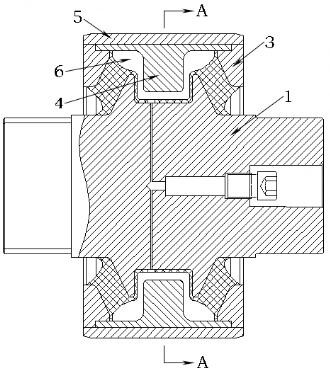

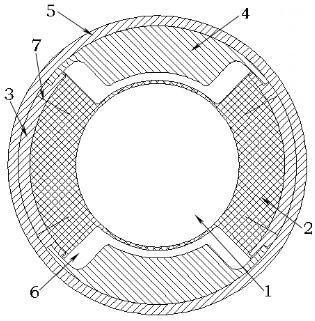

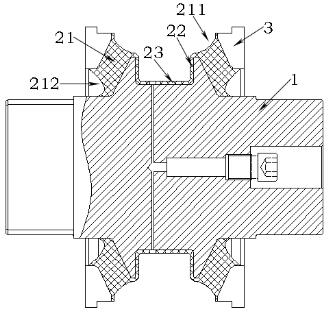

[0030] Such as figure 1 , figure 2 and image 3 As shown, the vulcanized body casing 3 is set as a split type casing, a gap 7 is set between two adjacent vulcanized body casings 3, and the rubber body 2 is vulcanized between the vulcanized body casing 3 and the mandrel 1, and The gap 7 between the vulcanized body jackets 3 extends into the rubber body 2 . Press the stop block 4 and the vulcanized body casing 3 tightly, so that the rubber body 2 is pre-compressed, and the gap 7 in the vulcanized body casing 3 and the rubber body 2 is completely closed, and the pre-compressed whole is assembled into the overall casing 5 , so as to assemble the split type liquid rubber composite node. And the mandrel 1, the rubber body 2 and the vulcanized body jacket 3 together form a hydraulic cavity 6 with an outer opening. The hydraulic cavity 6 is provided with a stop block 4, and the longitudinal section of the stop block 4 is T-shaped. The upper end of the stop block 4 is closed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com