Zn-Ge-Cu-Si-P high-entropy alloy material used as negative electrode of lithium ion battery and preparation method for Zn-Ge-Cu-Si-P high-entropy alloy material

A zn-ge-cu-si-p, lithium-ion battery technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., to achieve the effects of reducing material costs, improving electrochemical performance, and relieving stress and strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present inventors synthesized multiple alloy negative electrode material and a carbon composite material mainly by high energy ball milling, preparation method includes the following steps to Zn :( 0.5 GE 0.5 Cu 0.5 Si 0.5 P 2 For example)

[0044] ① the zinc, germanium powder (Macklin, 99.999%), copper powder (Macklin, 99.9%), molar ratio of silica fume (Aladdin, 99.9%) and red phosphorus (Macklin, AR98.5%) according to a specific (1: 1: 1: 1: 4) were weighed and proportion, into a stainless steel ball mill jar, the ball material than stainless steel beads and the powder material is 20: 1, into a stainless steel jar filled with an inert atmosphere (Ar gas protection) glove box (anhydrous oxygen-free, the oxygen content of water <1ppm), in the glove box of stainless steel jar tightly encapsulated (for locking and sealing with a locking device).

[0045] ② stainless steel jar remove the glove box, mounted on a ball mill for tightening and fixing, provided rotation speed ...

Embodiment 2

[0048] Preparation Example 1 with reference to embodiments, adjustment zinc, germanium powder, copper powder, silicon powder, and red phosphorus molar ratio, were prepared Zn 0.8 GE 0.8 Cu 0.2 Si 0.2 P 2 , Zn 0.7 GE 0.7 Cu 0.3 Si 0.3 P 2 , Zn 0.6 GE 0.6 Cu 0.4 Si 0.4 P 2 , Zn 0.4 GE 0.4 Cu 0.6 Si 0.6 P 2 , Zn 0.3 GE 0.3 Cu 0.7 Si 0.7 P 2 , Zn 0.2 GE 0.2 Cu 0.8 Si 0.8 P 2 High-entropy alloys.

[0049]

[0050]

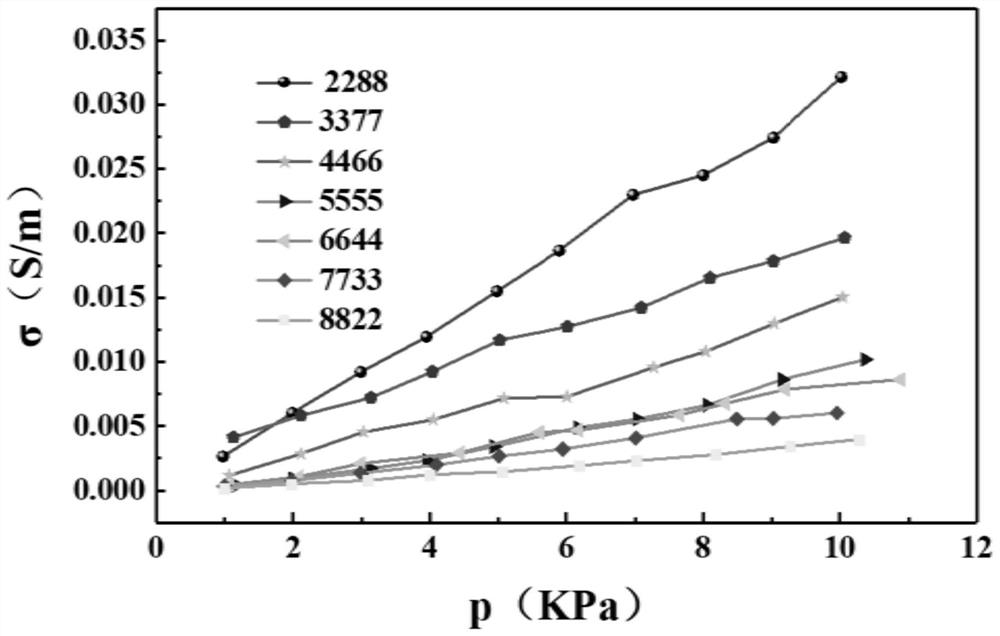

[0051] The material obtained above embodiment detects the following results:

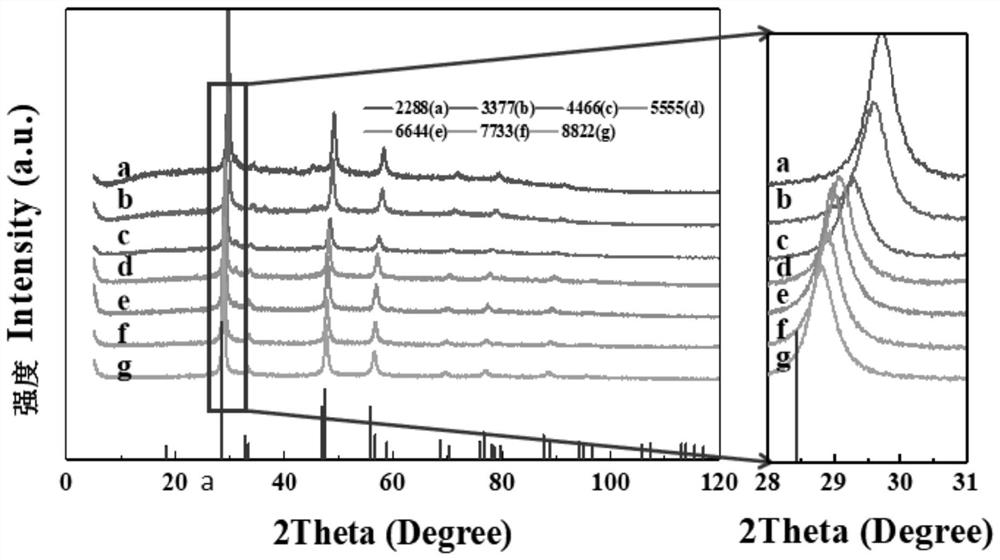

[0052] (1) X- ray diffraction pattern of Zn-Ge-Cu-Si-P alloy material high entropy synthetic

[0053] like figure 1 Shown, it can be seen from the diffraction pattern, synthesized the alloys with high entropy ZnGeP 2 Consistent with the diffraction peaks, diffraction peaks of the components of a simple substance element have disappeared, indicating that the material has been completely reacted, with high yield and purity. With the reduction and Zn, Ge content, since Si is smaller than the ato...

Embodiment 3

[0063] On the basis of the embodiment 1, the adjustment step ②, ③ the step of milling time, specifically:

[0064] ② stainless steel jar remove the glove box, mounted on a ball mill for tightening and fixing, provided rotation speed of 400 rpm ball mill, ball mill a single time of 1 hour, 30 minute intervals, 13 times the number of repetitions, i.e. a total of 19.5 hours milling time, can be obtained formed by high entropy Zn Zn, Ge, Cu, Si, P element 0.5 Ge 0.5 Cu 0.5 Si 0.5 P 2 Compound.

[0065] The high entropy step ② ③ obtained Zn 0.5 Ge 0.5 Cu 0.5 Si 0.5 P 2 A compound with a carbon material (SuperP) in accordance with a predetermined mass ratio: for (63) were weighed, added to a stainless steel ball mill jar, the ball material than stainless steel beads and the powder material is 20: 1, is provided a ball mill speed of 400 rpm, a single milling time of 1 hour, 30 minute intervals, 11 times the number of repetitions, i.e. a total of 16.5 hours milling time, Zn can be obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com