Flexible hinge and floating frame matched clamping and positioning device for optical component

A technology of flexible hinges and optical components, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of rigid connection, the position and posture of optical components cannot meet the repair processing, and accumulated on the air-floating frame, etc., to achieve smooth operation, Reliable large range of motion, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

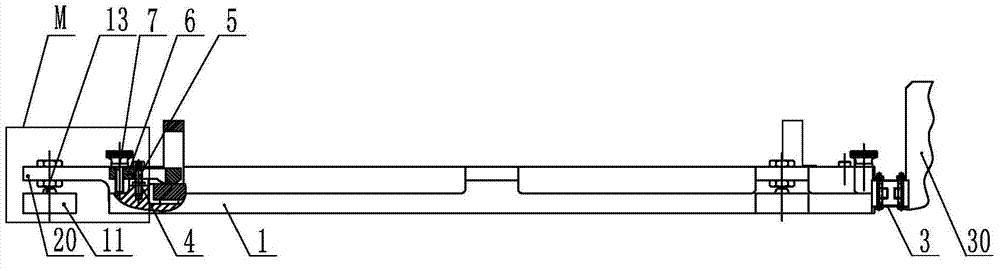

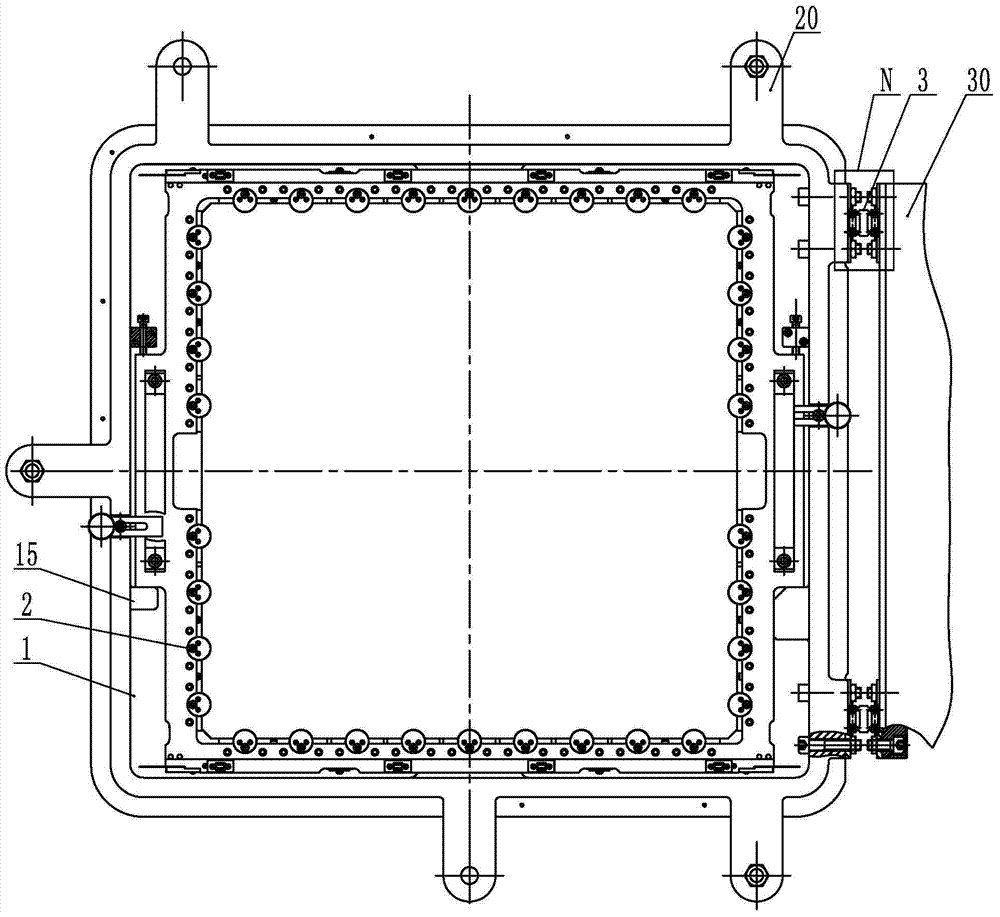

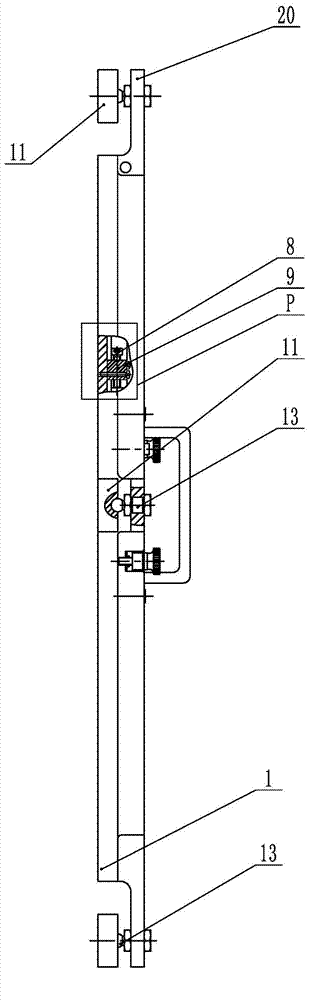

[0020] Specific implementation mode one: combine Figure 1-Figure 22 and Figure 24-Figure 26 Explain that the flexible hinge of this embodiment cooperates with the air-floor frame to be used for clamping and positioning of optical components. Pad 11, three spherical hinge studs 13 and two groups of flexible hinges 3, the air float frame includes a crystal frame 1, two compression blocks 6, two positioning screws one 8, two positioning screws two 7, two Locking block 9, two positioning blocks 15 and five connecting ears 20;

[0021] The crystal frame 1 is a rectangular frame arranged horizontally (it is the main part of the whole device), and two sets of flexible hinges 3 are fixed to the same arbitrary outer surface of the crystal frame 1 (by bolts and nuts); the remaining three of the crystal frame 1 Five connecting ears 20 are fixed on the outer surface, and a positioning block 15 is respectively fixed on two opposite inner surfaces of the crystal frame 1, and a positioni...

specific Embodiment approach 2

[0038] Embodiment 2: The distribution of the five connecting ears 20 in this embodiment on the remaining three outer surfaces of the crystal frame 1 is as follows: One connecting ear 20 is affixed to the outer surface of the crystal frame 1, and two connecting ears 20 are affixed to each outer surface of the crystal frame 1 perpendicular to the side on which two groups of flexible hinges 3 are fixed. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the distribution of the five connecting ears 20 in the present embodiment on the remaining three outer surfaces of the crystal frame 1 is as follows: on the crystal frame 1, the side perpendicular to the side where two groups of flexible hinges 3 are fixed Two connecting ears 20 are affixed to one of the two outer surfaces, and a connecting ear is affixed to the other of the two outer surfaces perpendicular to the side on which two groups of flexible hinges 3 are fixed on the crystal frame 1 20. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com