Control method of compound PLC (programmable logic controller) air conditioning automatic control system in textile mill

A technology of automatic control and control method of air conditioning, applied in the direction of air conditioning system, heating and ventilation control system, heating and ventilation safety system, etc. Energy consumption, ensure the effect of production process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

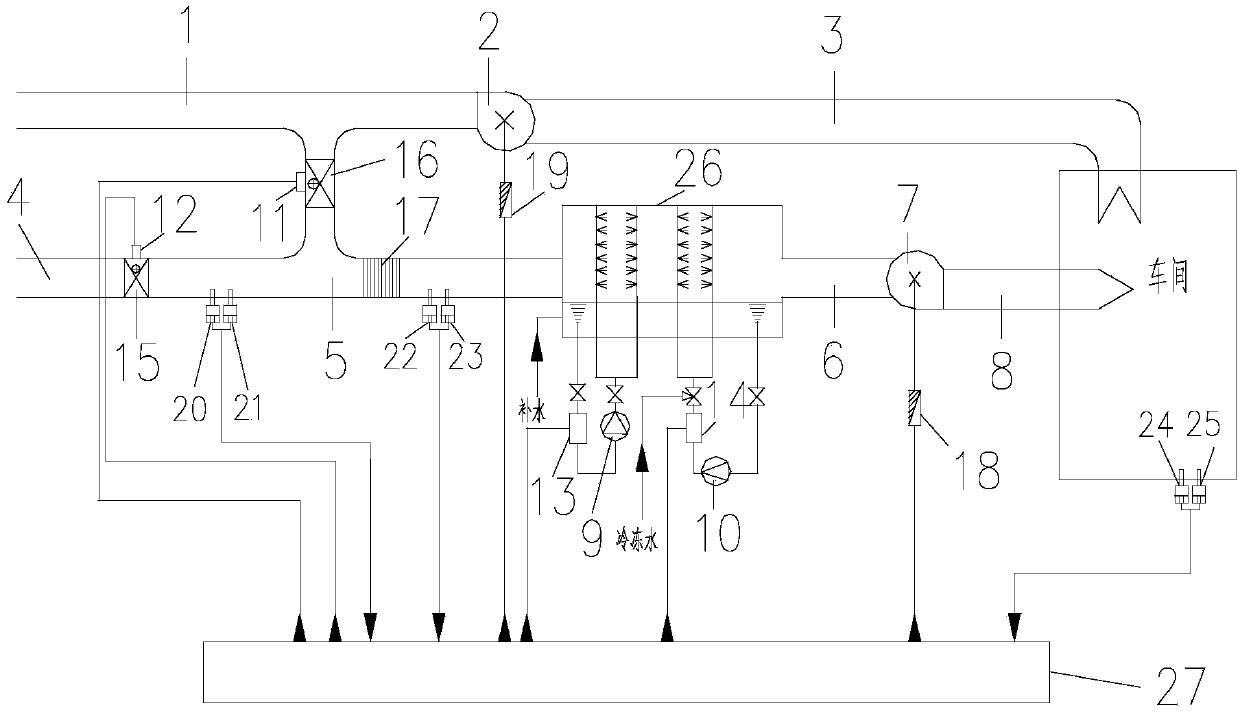

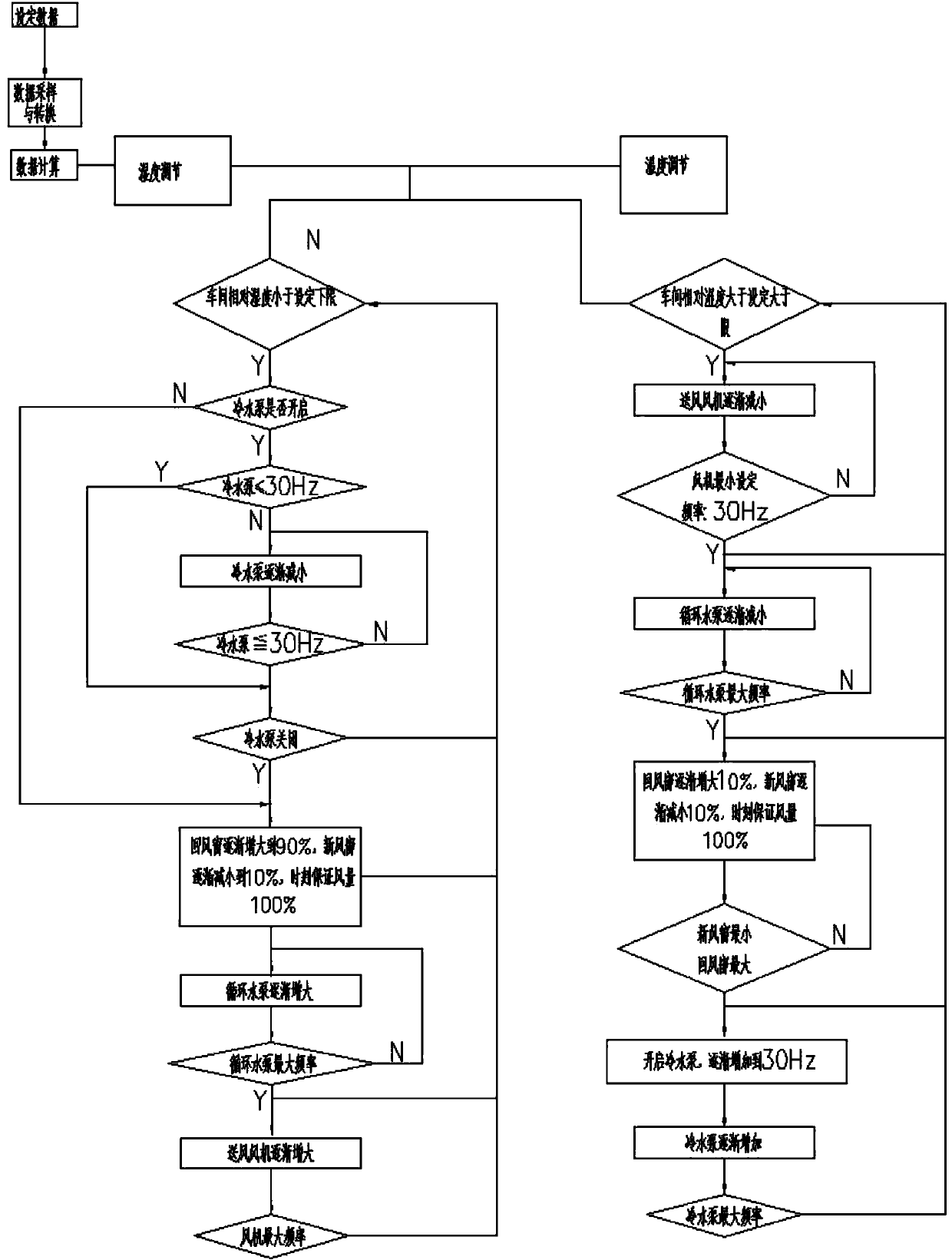

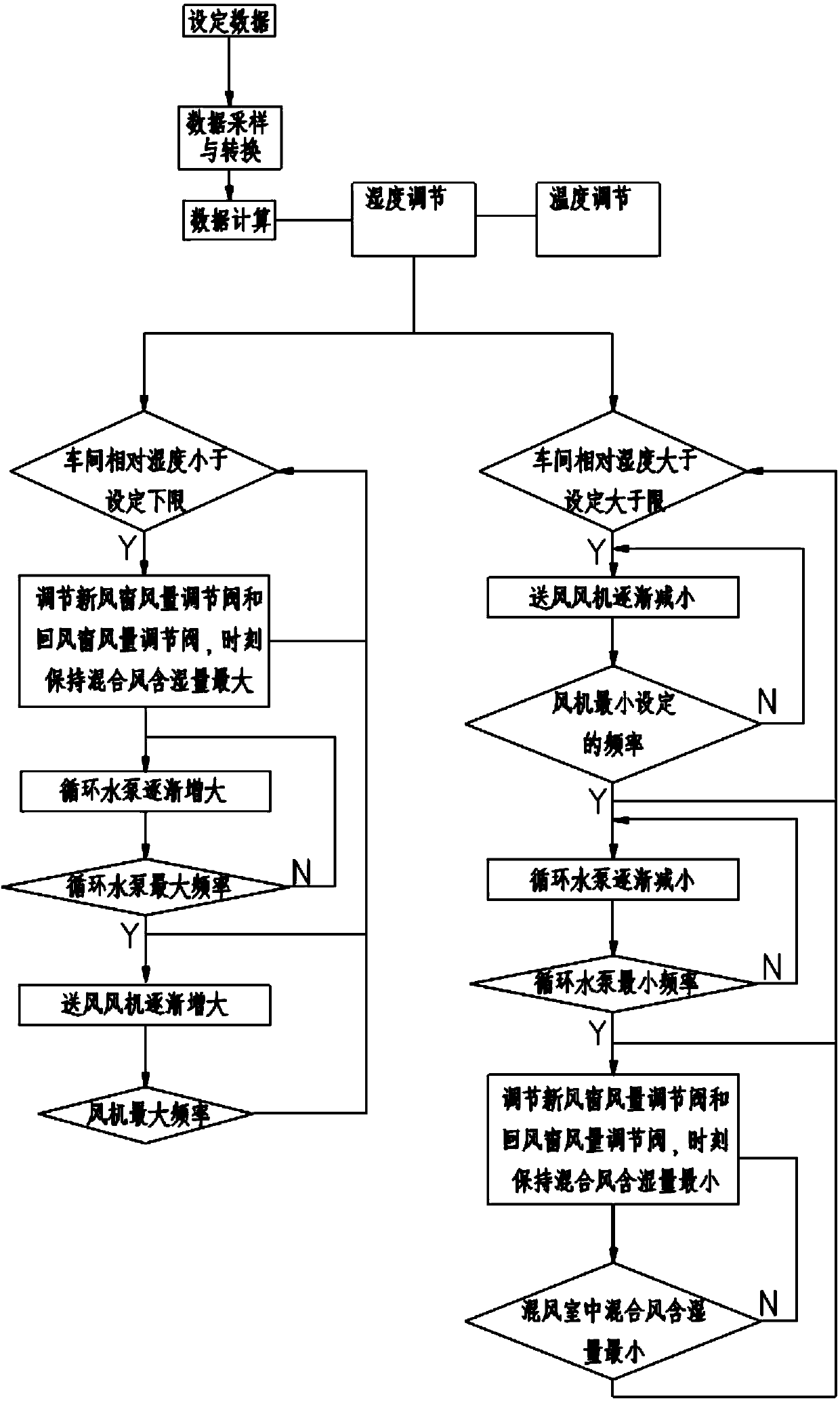

Method used

Image

Examples

Embodiment

[0039] Select a workshop air-conditioning system to describe in detail the control and adjustment of the workshop air temperature and humidity.

[0040] Select the working condition that the actual humidity of the workshop is less than the set value. First, set the relative humidity of the workshop as 55%, and the actual humidity is Divided into four humidity ranges, the control routes are: (1) That is, when the difference between the relative humidity of the workshop and the set value is less than 1%, the air conditioner will maintain the original working state at the next moment. (2) When the difference between the relative humidity and the set value is 1% to 3%, the fresh air window 15 is closed by 10% every 5 seconds, and the return air window 16 is opened by 10% every 5 seconds. In order to ensure a certain amount of fresh air volume, until the fresh air window The opening degree of 15 is 10% and the opening degree of air return window 16 is 90%. During this peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com