Intermittent automatic turning and sieving device

An automatic turning and intermittent technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of worn equipment, small belt top dead, and accumulation, so as to reduce the possibility of equipment damage and reduce labor volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

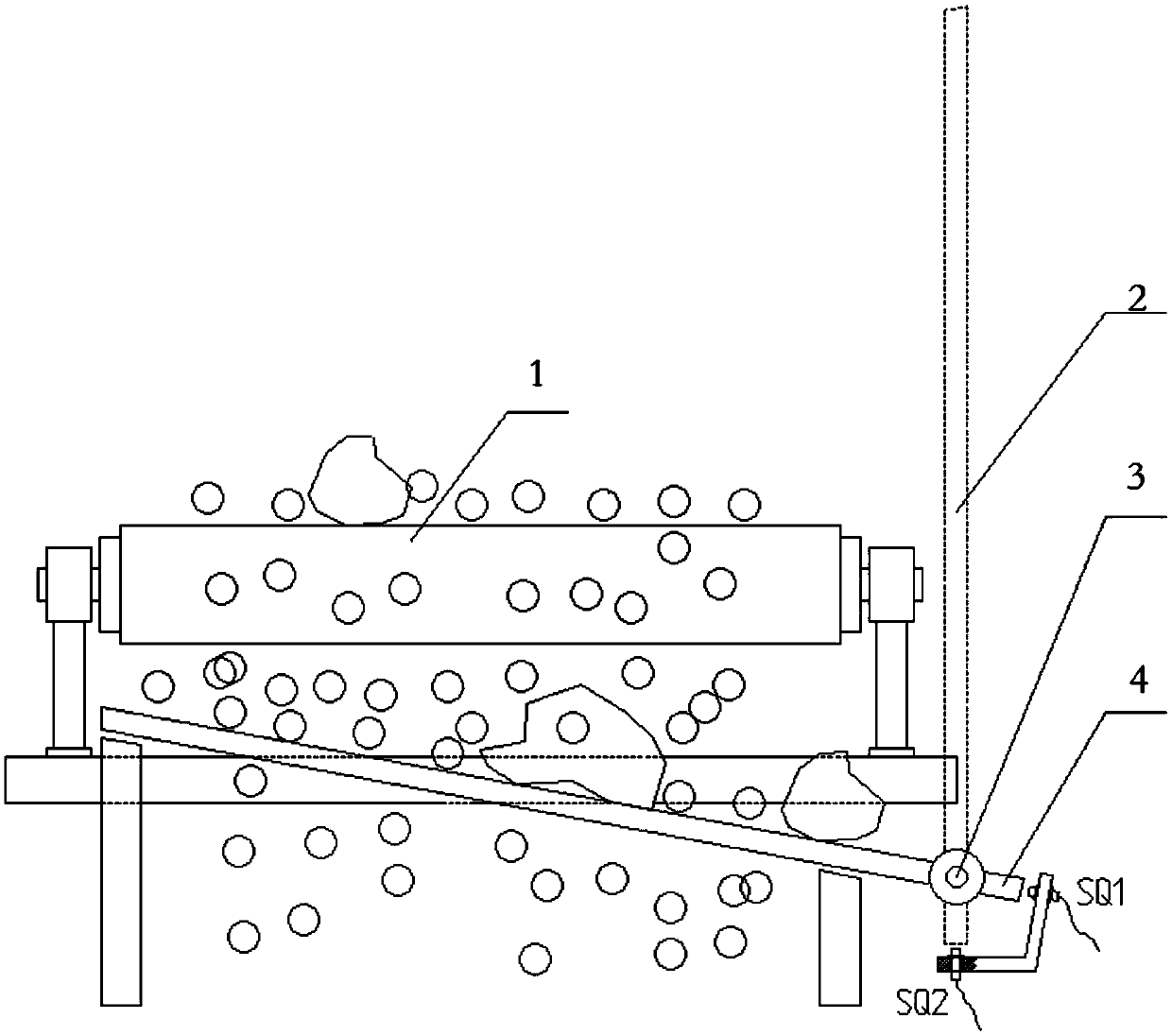

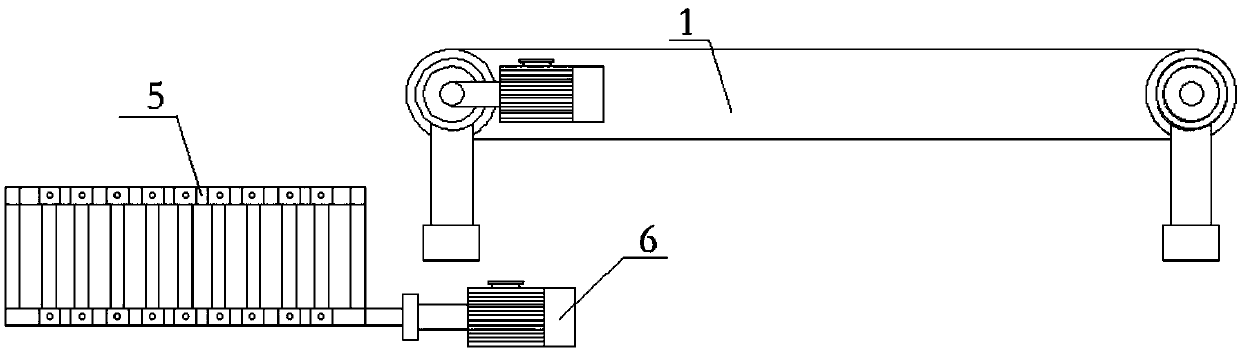

[0017] see Figure 1-3 , an intermittent automatic sieve turning device, including a sieve 2 located on a conveyor belt 1, the sieve 2 and the fixed bracket at its installation position are rotatably connected by a lower end rotating shaft 3, and the lower end rotating shaft 3 is connected to a motor 6. The two sides of the rotating shaft 3 at the lower end are the high section and the low section of the sieve 2 respectively, and a driver is provided at the lower section of the sieve 2. The driver has a proximity switch SQ1 and a proximity switch SQ2 outside the driver. The drive circuit for the intermittent operation of the motor 7;

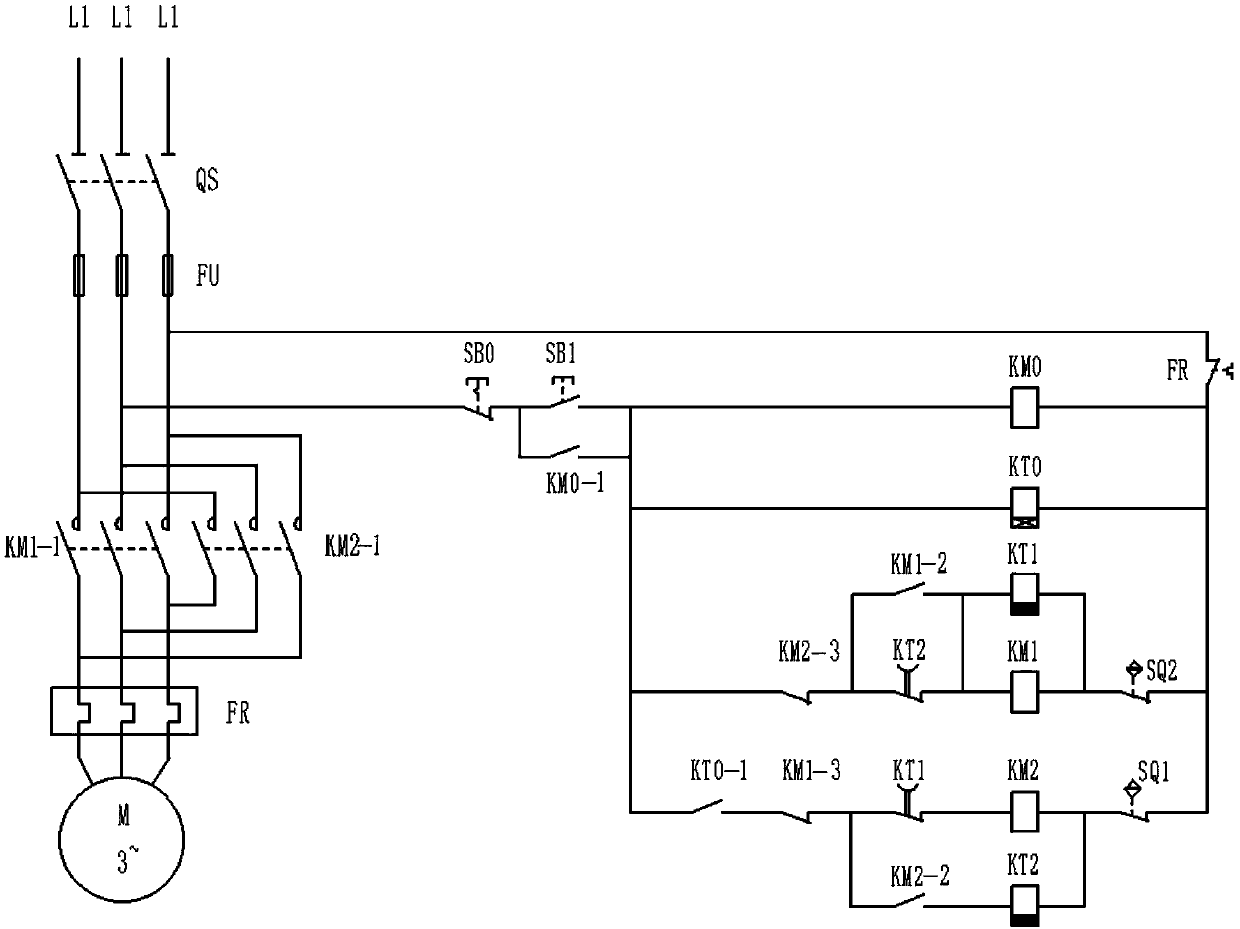

[0018] The drive circuit includes two contact switches KM1-1 and KM2-1 connected to the motor 6, the contact switch KM1-1 is sequentially connected to the proximity switch SB0 and the start button SB2, and the other end of the start button SB2 is connected to the contactor coil KM0 , KT1, KM1, KM2 and KT2;

[0019] The contactor coil KM0 is al...

Embodiment 2

[0026] The difference from Example 1 is that, in order to facilitate the screening of different mineral materials, the sieve 2 is composed of a plurality of sieve bars fixed in the frame by adjustable screws 5, and the gap between the sieve bars is changed to deal with different Precision screening needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com