Friction power device used for tube rotation

A technology for power devices and lamps, which is applied in the manufacture of discharge tubes/lamps, electrical components, and cold cathodes, etc., can solve the problems of large power consumption, prone to failure, and high cost, and achieves low energy saving, less failure, and higher cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described with reference to the drawings and specific embodiments, but does not constitute any limitation to the present invention.

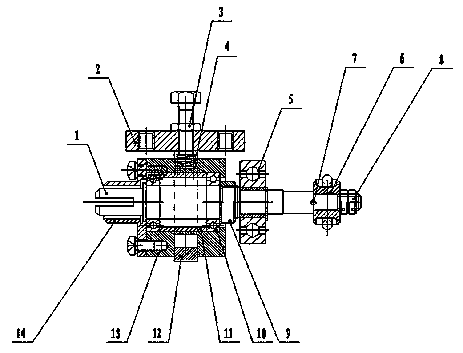

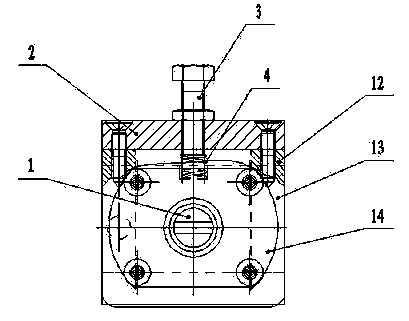

[0011] like figure 1 , figure 2 As shown, a friction power device for lamp tube rotation, the friction power device mainly includes a friction plate fixed on the base of the energy-saving lamp production equipment and a friction wheel 6 that rubs against the friction plate to generate relative rotation; the described The friction wheel 6 is arranged on one end of the main shaft 1, and is tightened by two nuts 8, and is used to fix the pin shaft 7 of the friction wheel on the main shaft, and the described pin shaft 7 is perpendicular to the main shaft; the other end of the main shaft 1 is connected to the flexible shaft Connected to form a power output shaft, which is connected with the lamp rotation mechanism; the main shaft 1 is connected in the movable shaft seat 13 through the bearing I10; the movable shaft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com