Large and small textile mill environment self-adaptation air conditioner with absorption refrigeration and evaporation cooling combined

An evaporative cooling air conditioning and evaporative cooling technology, which is applied in air conditioning systems, applications, space heating and ventilation, etc. It can solve the problems of large air supply volume of air conditioning systems, operator discomfort, and increased energy consumption, and meet process requirements. , The effect of reducing the air supply volume and preventing the blockage of the flow channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

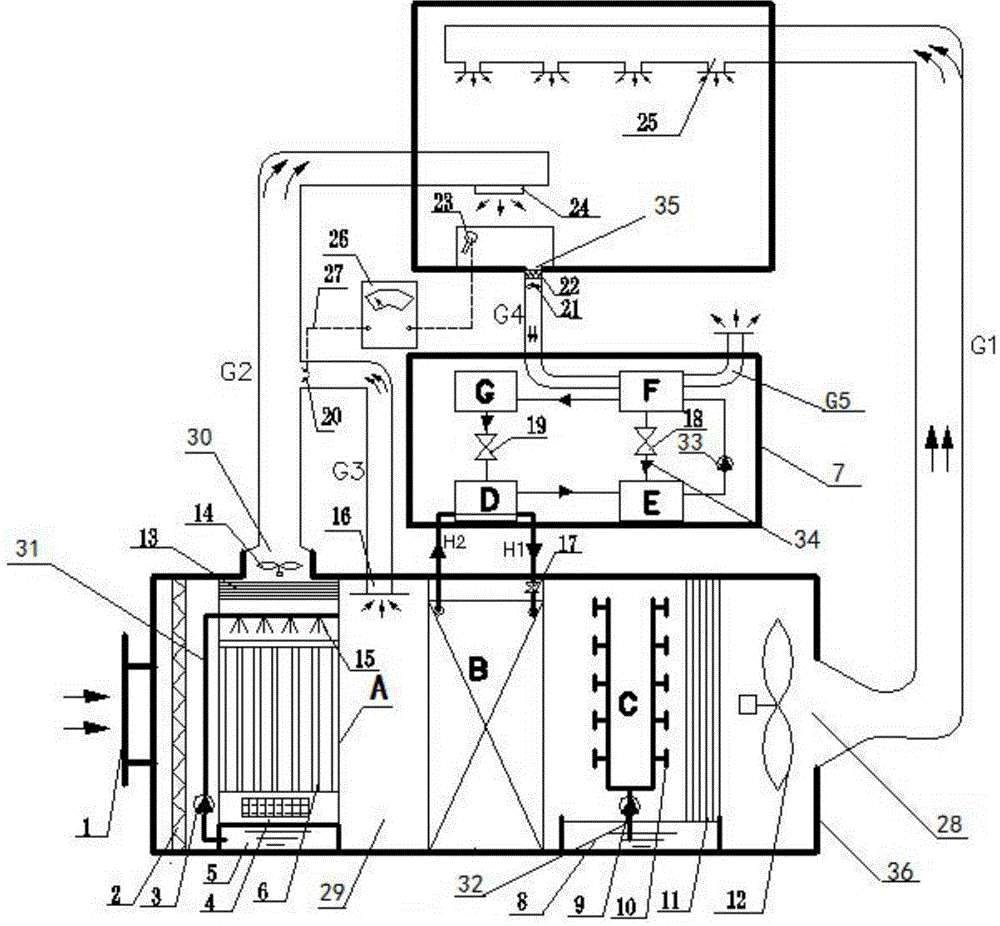

[0026] The present invention combines absorption refrigeration and evaporative cooling to adapt to the environment of textile mills, and its structure is as follows: figure 1 As shown, there is a composite evaporative cooling air conditioner unit 36, the composite evaporative cooling air conditioner unit 36 is connected with the lithium bromide absorption chiller 7 through the water pipe group, the composite evaporative cooling air conditioner 36, the lithium bromide absorption chiller 7 are respectively connected to the textile mill Large and small environments are connected.

[0027] The composite evaporative cooling air conditioner unit 36 includes an organic unit casing, and the opposite side walls of the unit casing are respectively provided with an air inlet 1 and an air supply outlet 28, and the air filter a2 is arranged in the uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com