Bobbin exchanger

A technology of switches and bobbins, applied in textiles and papermaking, etc., can solve the problems of inability to use and popularize in a large area, labor and effort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

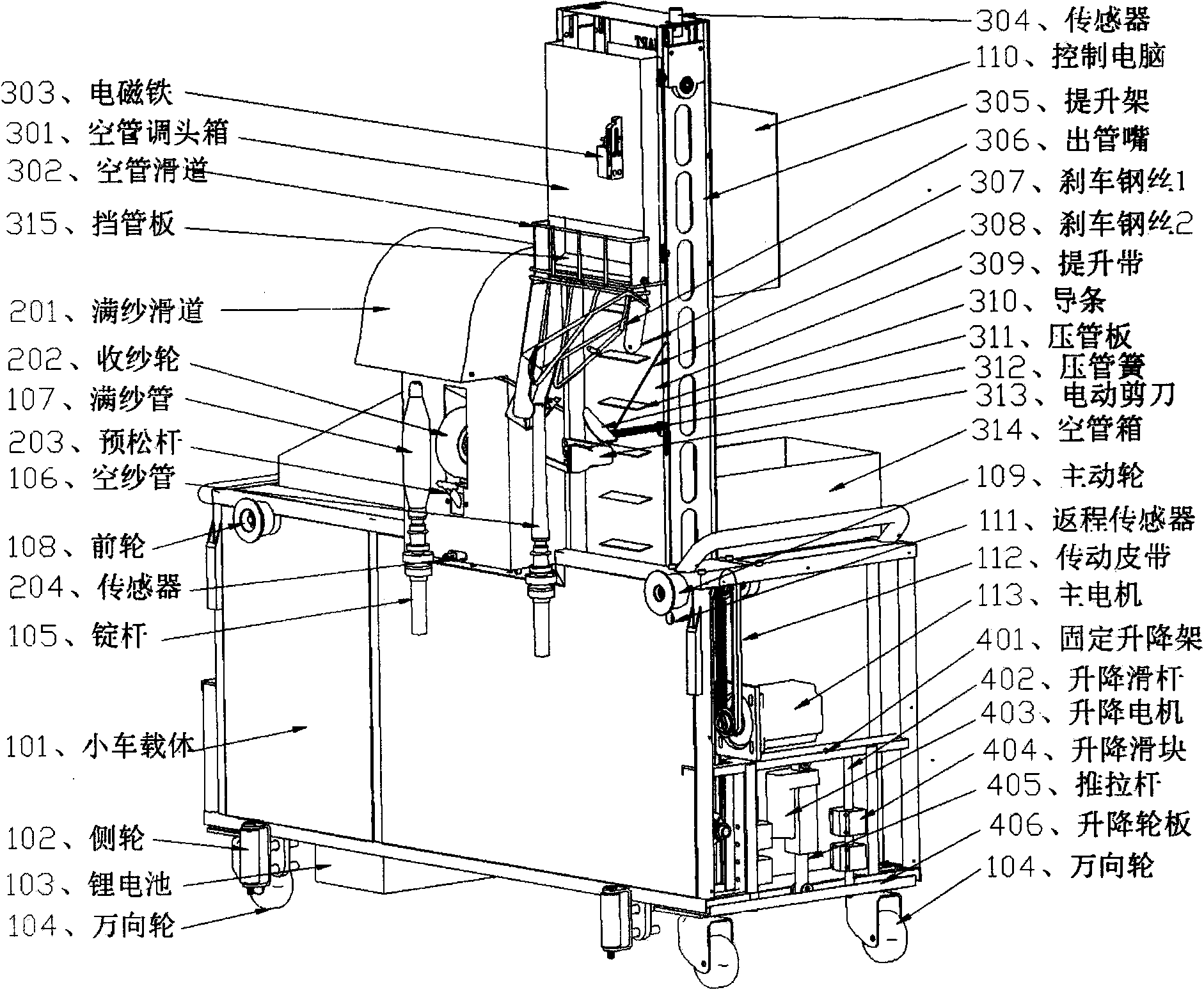

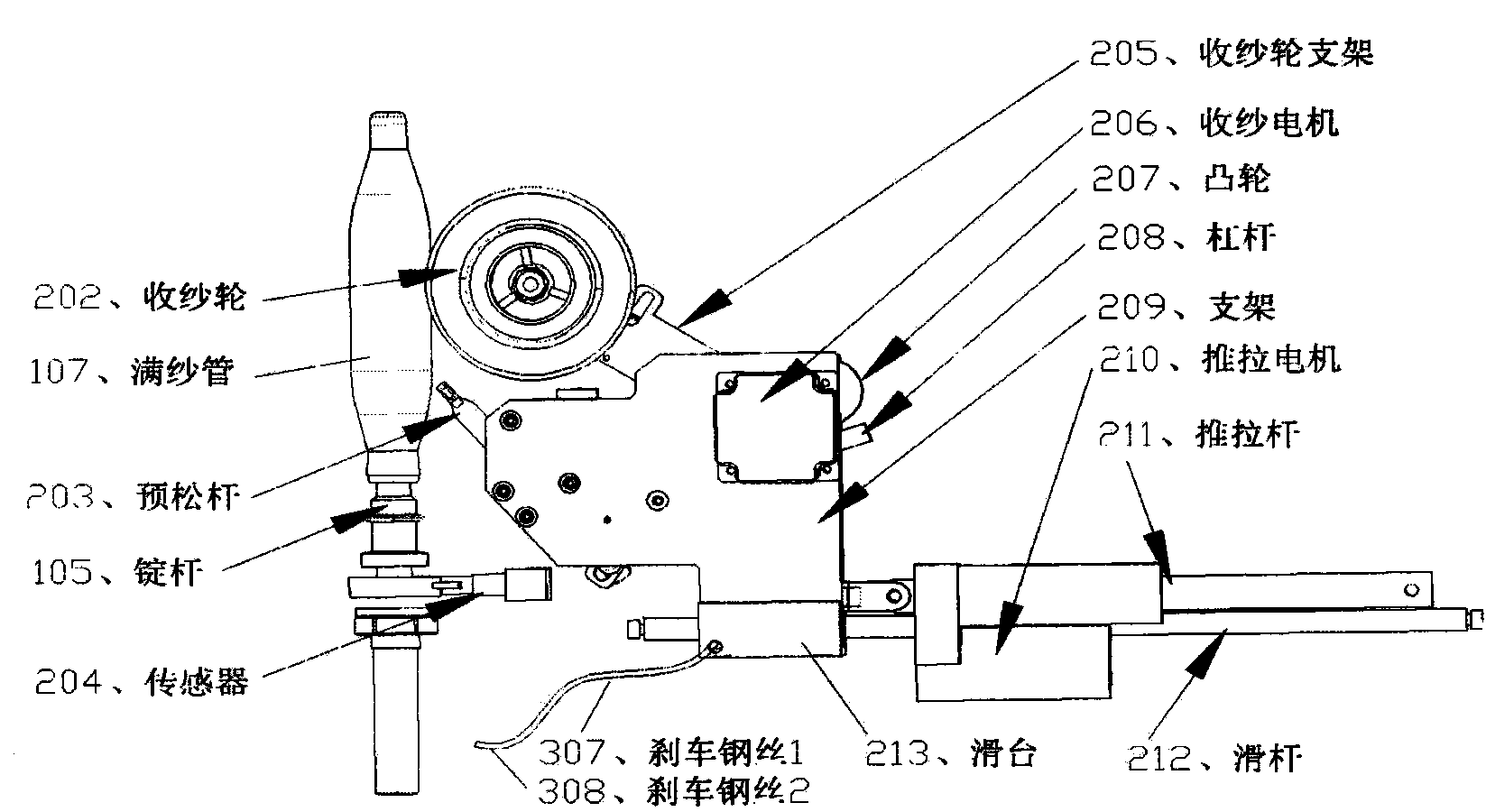

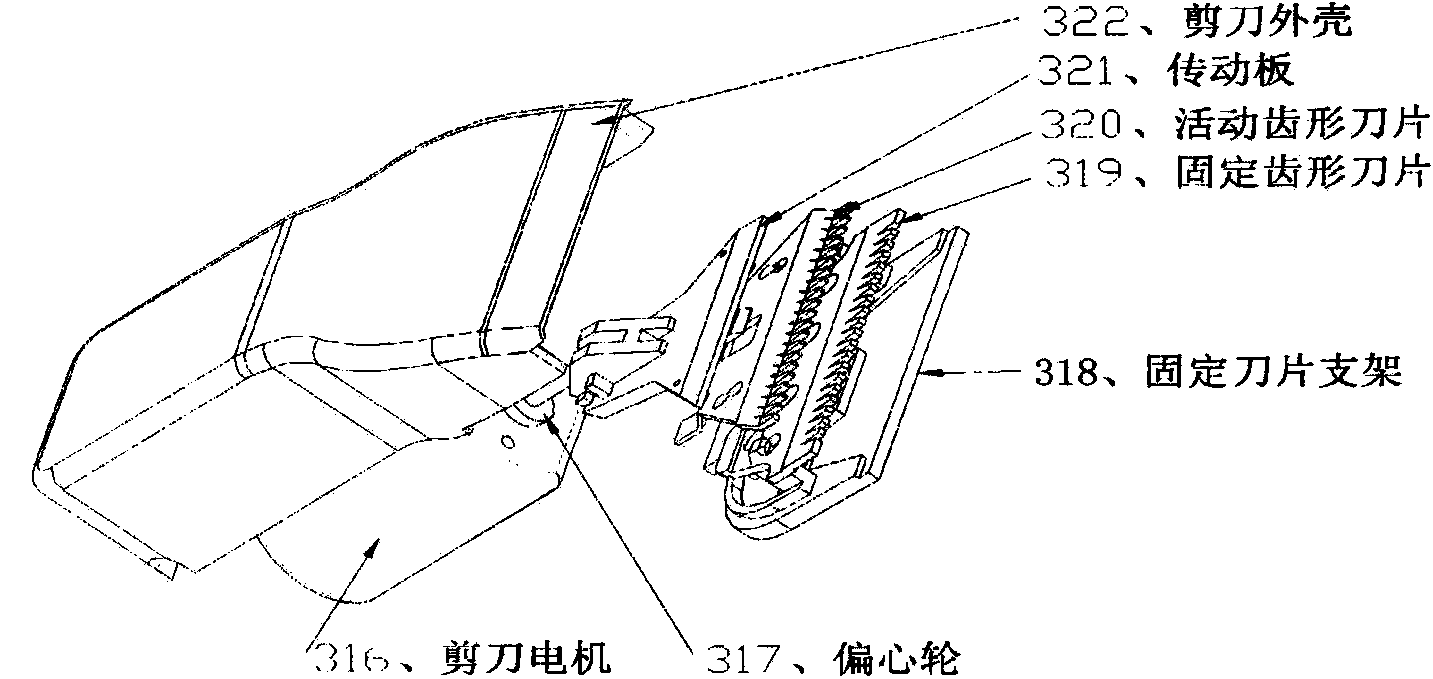

[0029] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0030] Preliminary preparation and positioning of the bobbin exchange of the present invention: as figure 1 As shown, when a certain spinning frame needs to doff, the bobbin switch trolley carrier 101 is pushed to the head or tail of the spinning frame, and is docked with the upper and lower tracks of the spinning frame.

[0031] Press the lifting button switch, command the lifting motor 403 of the lifting and anchoring device to work forward, and drive it to the push-pull rod 405, stretch out, withstand the lifting wheel plate 406, the universal wheel 104, and react with the ground to jack up the trolley carrier 101, Make front wheel 108, and driving wheel 109, hang on the spinning frame upper track, side wheel 102, lean against behind the spinning frame lower track.

[0032] Press the lifting switch again, instruct the lifting motor 403 of the lifting and anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com