Automatic single-body doffer

A doffing machine, automatic technology, applied in textiles and papermaking, etc., can solve problems such as labor-intensive, insufficient machine installation area, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

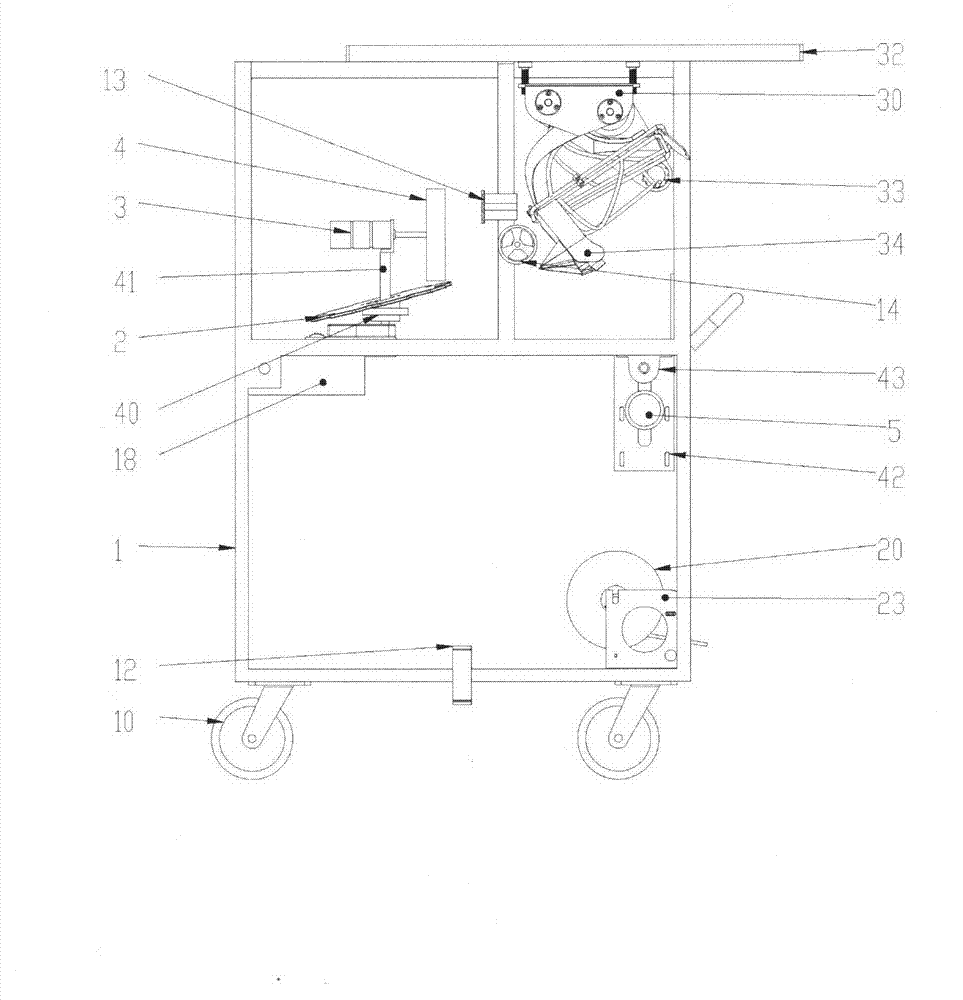

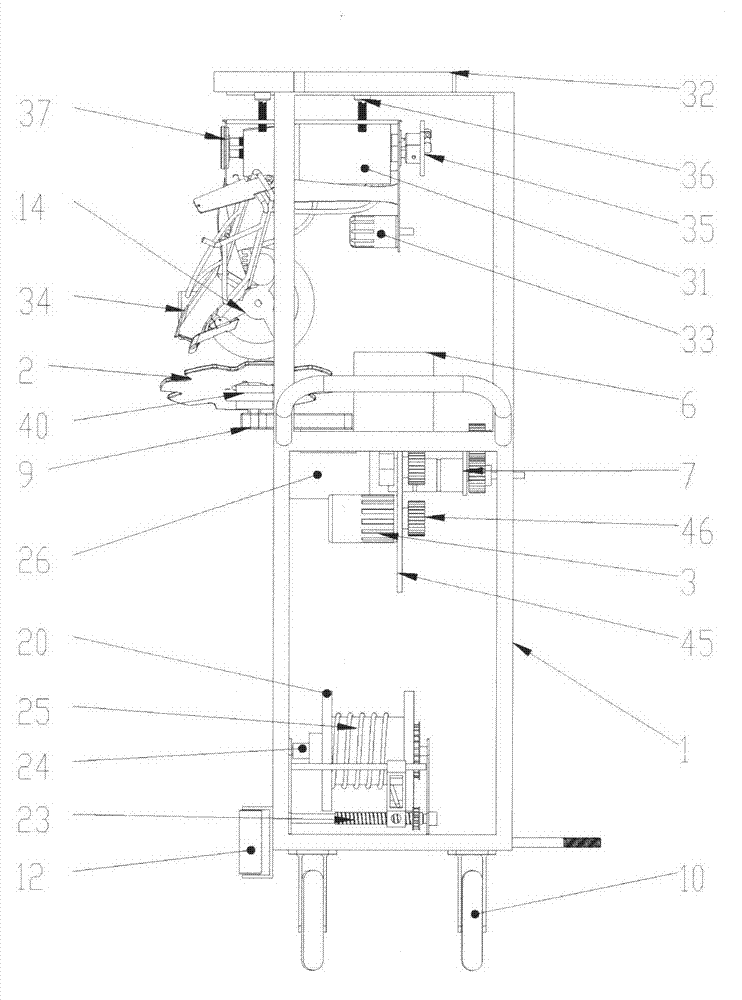

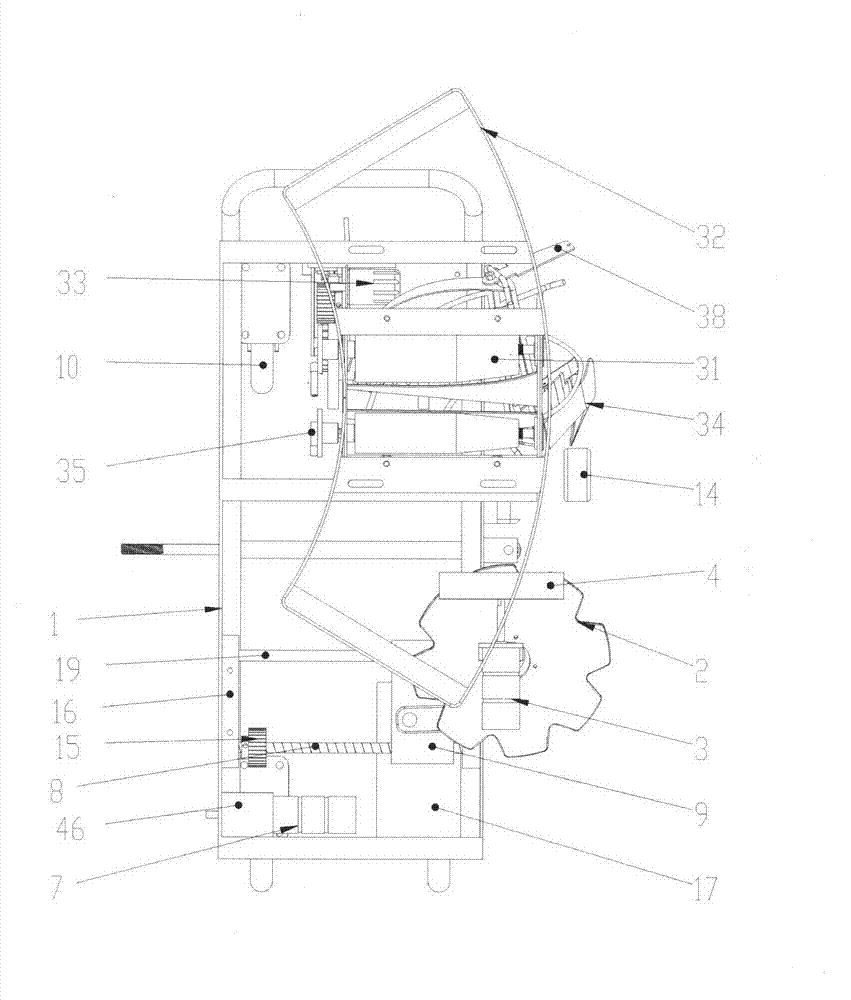

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0023] Early stage preparation and positioning of monomer automatic doffing machine of the present invention: as figure 1 As shown, when a spinning frame needs doffing, push the doffer trolley carrier 1 to the front or rear of the spinning frame, and dock with the upper and lower tracks of the spinning frame, and connect the power wire 25, or the battery 17, , turn on the power switch 60, start the work button 61, by the control system 6, the communication cable 62, the positioning sensor 63, the instruction walking motor 5, drive the driving wheel 11 on the synchronous belt 46, the transmission shaft 64, drive the trolley carrier 1, , Make the trolley carrier 1. Move forward along the track of the spinning frame, and then start the doffing work.

[0024] like figure 1 As shown, the trolley carrier 1, through the control system 6, is powered by the power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com