Doffing mechanism

A doffer, full yarn technology, applied in textiles and papermaking, etc., can solve the problems of labor-intensive, insufficient installation area of the machine, and inability to use and popularize in a large area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in more detail below in conjunction with the accompanying drawings.

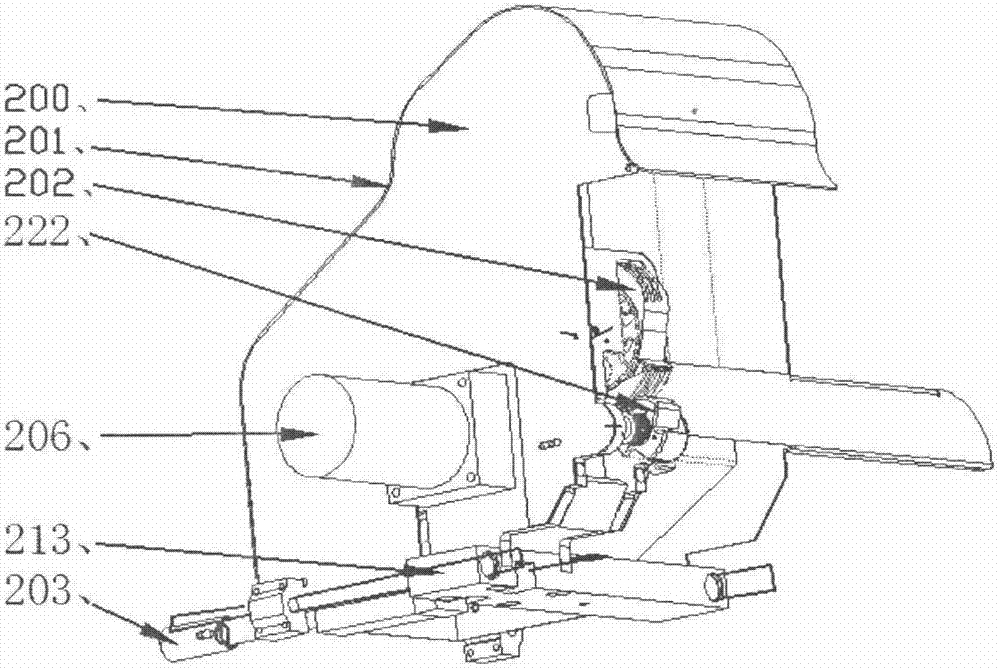

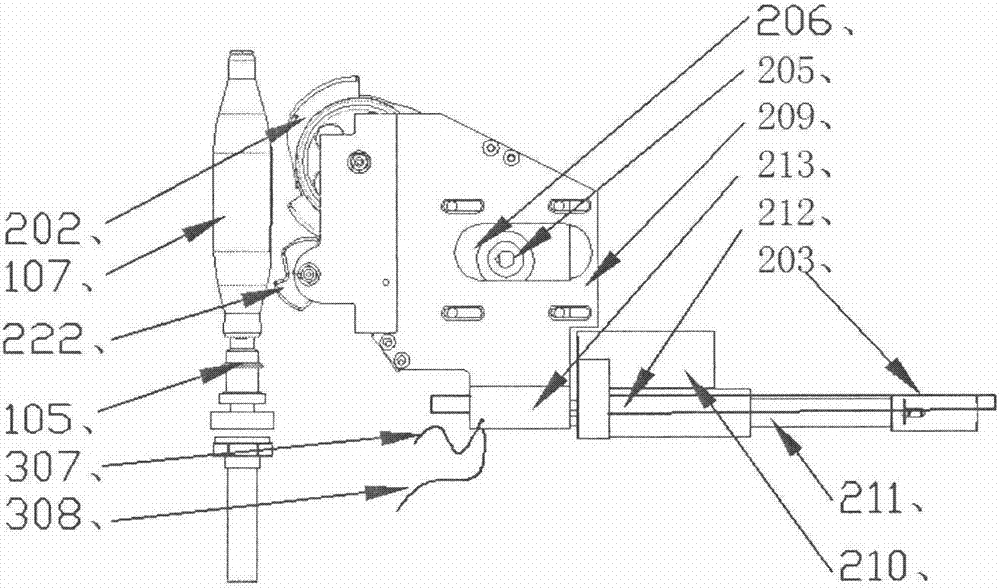

[0026] The doffing mechanism of the present invention: as figure 1 As shown, the mechanism includes an electric push-pull rod 211, a mobile slide 213, a bracket 209, a yarn receiving motor 206, a synchronous pulley 205, a pre-loosening wheel 222, a yarn receiving wheel 202, a full yarn slideway 201, and auxiliary transmission and fixing device.

[0027] Such as figure 2 Shown: slide bar 212, two ends are fixedly installed on the dolly carrier.

[0028] The mobile slide table 213, is sleeved on the slide bar 212, through a linear bearing.

[0029] One end of the push-pull rod 211 is installed on the mobile slide table 213, and the other end is fixedly installed on the dolly carrier.

[0030] The push-pull motor 210 drives the push-pull rod 211 through an internal worm gear, and can freely expand and contract as required.

[0031] Support 209 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com