Automatic vertical doffer

A doffer, fully automatic technology, used in textiles and papermaking, etc., can solve the problems of insufficient machine installation size and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

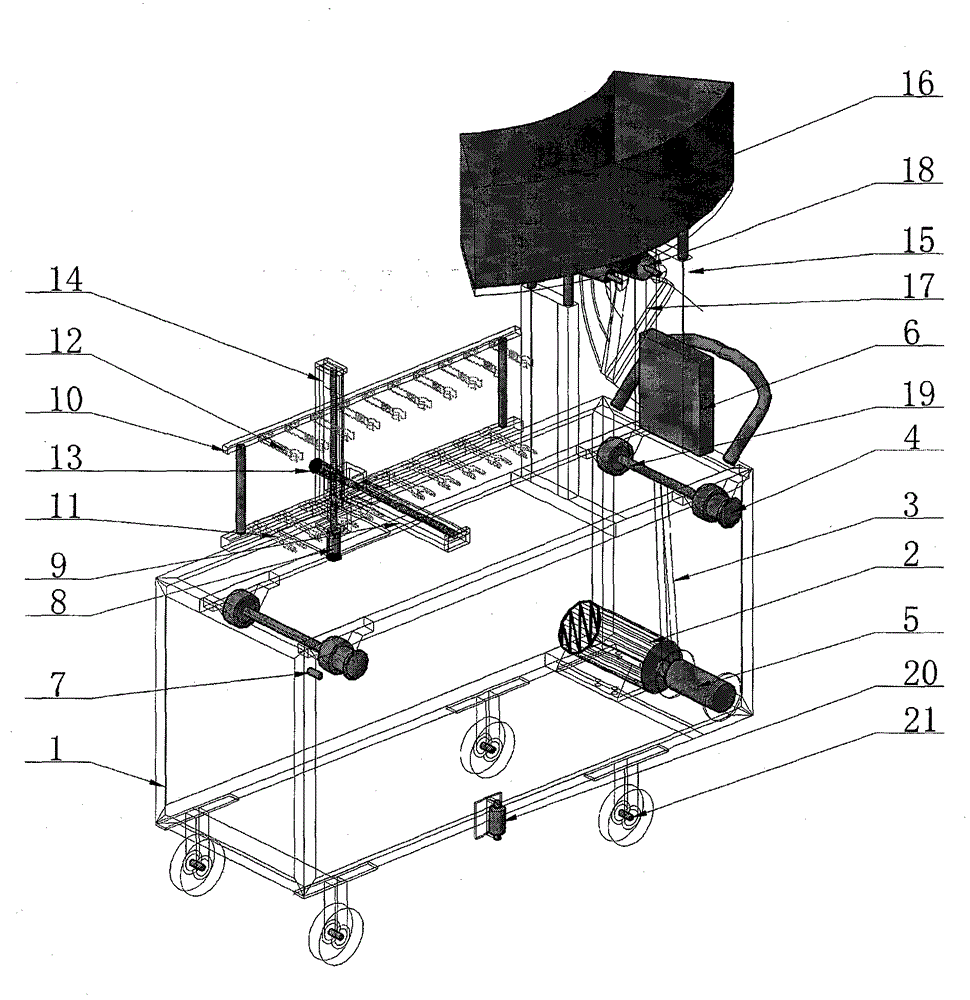

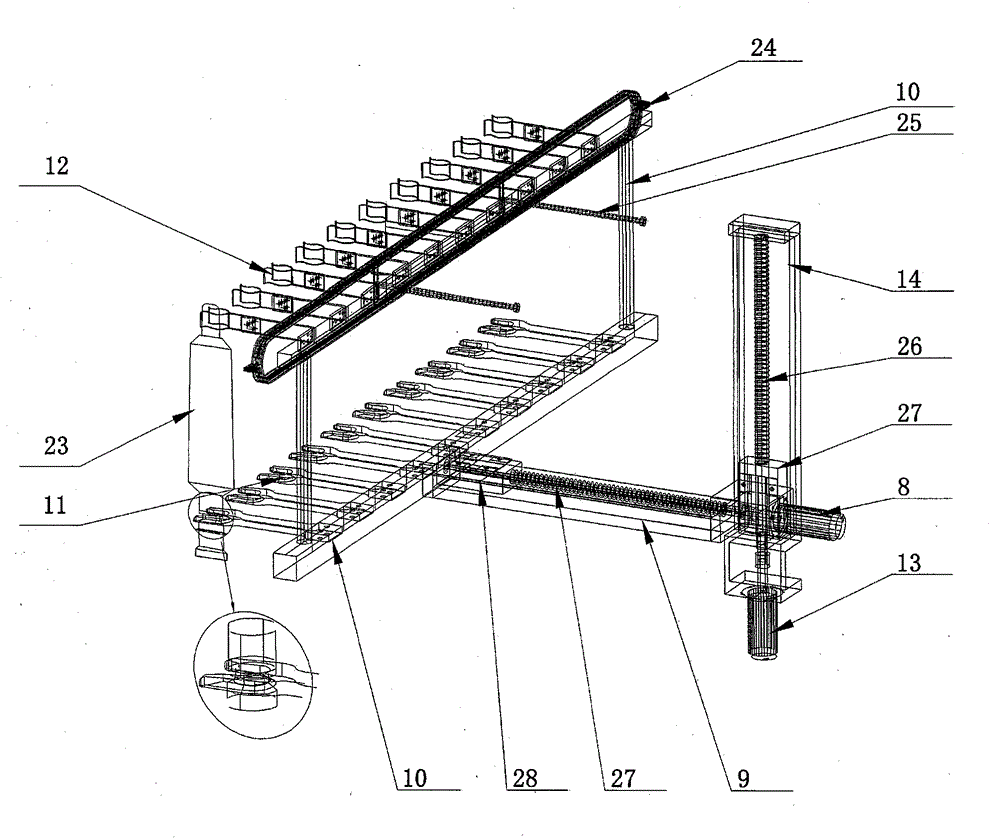

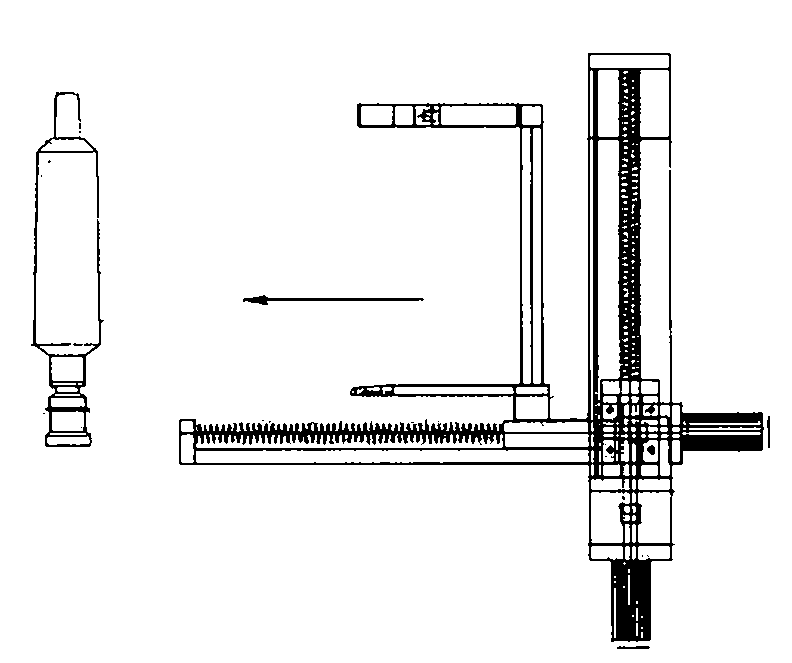

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0023] Preliminary preparation and positioning of the automatic vertical doffing machine of the present invention: as figure 1 As shown, when a spinning frame needs to doff, the doffer trolley carrier 1 is pushed to the head or tail of the spinning frame, and is docked with the spinning frame track. Insert the power cord plug 36, start the start button, the doffing machine is driven by the first motor 2 to the synchronous belt 3, the wheel shaft 19 drives the side wheel 4 of the trolley carrier 1, and the first motor moves forward along the spinning frame track. The forward movement of 2 will rotate on the gear 19 to drive the screw mandrel and slide block on the empty tube support 15 to act on the empty tube support 15 empty tube loading device 16, the tube driving device 18, and the S-shaped slideway 17 moves forward to the spun yarn Above the spinning frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com