Fine tail yarn eliminator

A technology of clearing machine and fine tail yarn, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., and can solve problems such as labor-intensive, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

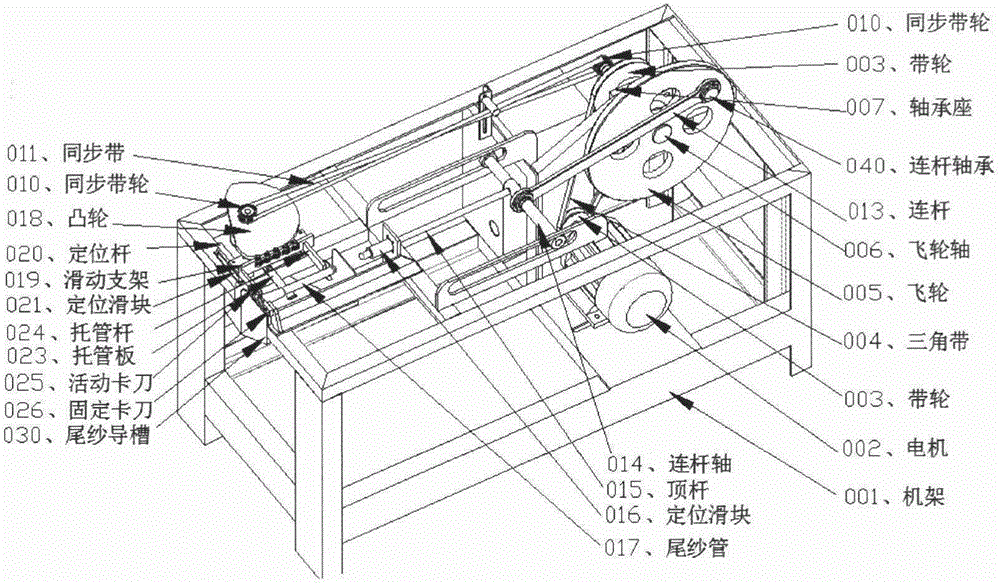

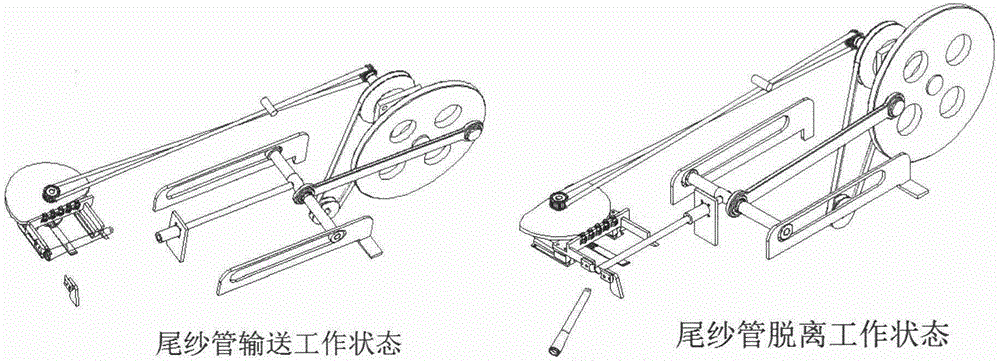

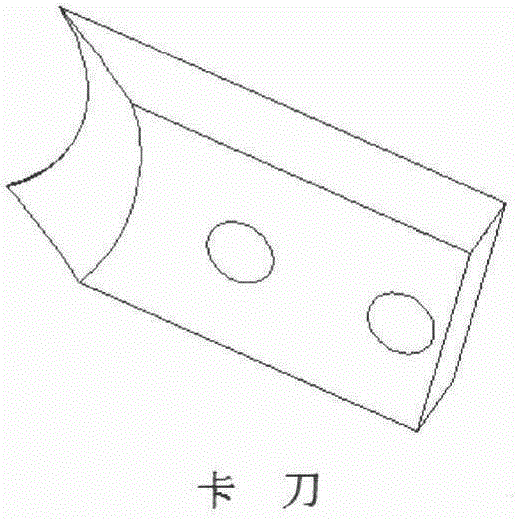

[0028] The patent of the present invention will be described in more detail below with reference to the accompanying drawings.

[0029] When the fine tail yarn needs to be removed, such as figure 1 As shown, press the power button 031, turn on the power, and then start the work button 032, the motor 002, and work.

[0030] Put the tail yarn bobbin 017 to be removed into the tail yarn tube guide groove 030 and the upper opening in different sizes.

[0031] The motor 002, through the pulley 003, the V-belt 004, is driven to the flywheel shaft 006 and the flywheel 005 installed in the frame 001, the middle, and rotates.

[0032] One end of the connecting rod 013 is installed on the other side of the flywheel 005 through the connecting rod bearing 040, and also rotates accordingly.

[0033] The connecting rod 013, the other end is installed on the connecting rod shaft 014, which slides back and forth through the connecting rod bearing 040, and the connecting rod shaft 014, both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com