Intelligent plaiting machine

A cloth coder and intelligent technology, which is applied in the field of intelligent control cloth coder, can solve the problems of high labor intensity, failure to meet customers, and low technical level, so as to save labor and avoid long and short code defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

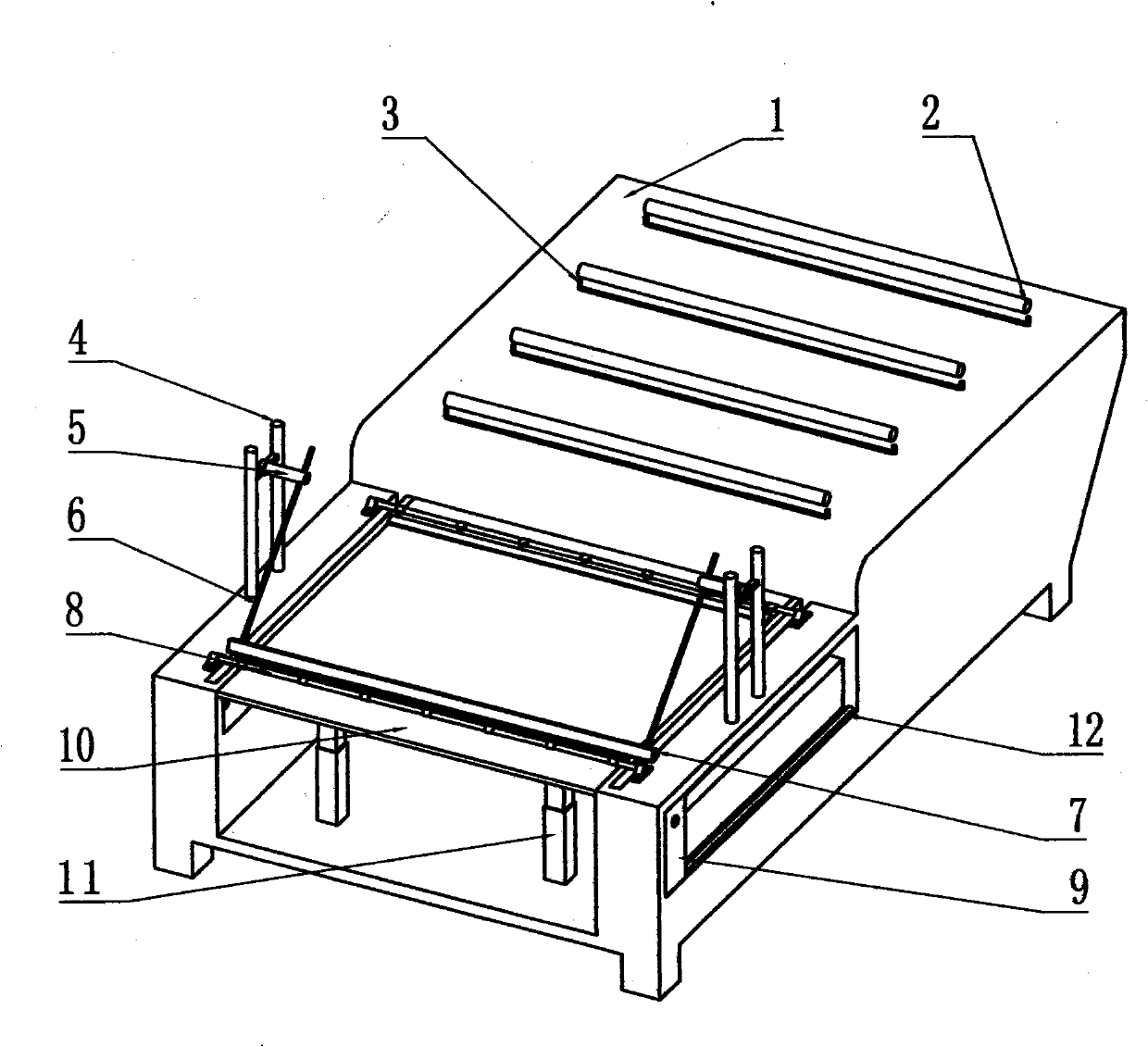

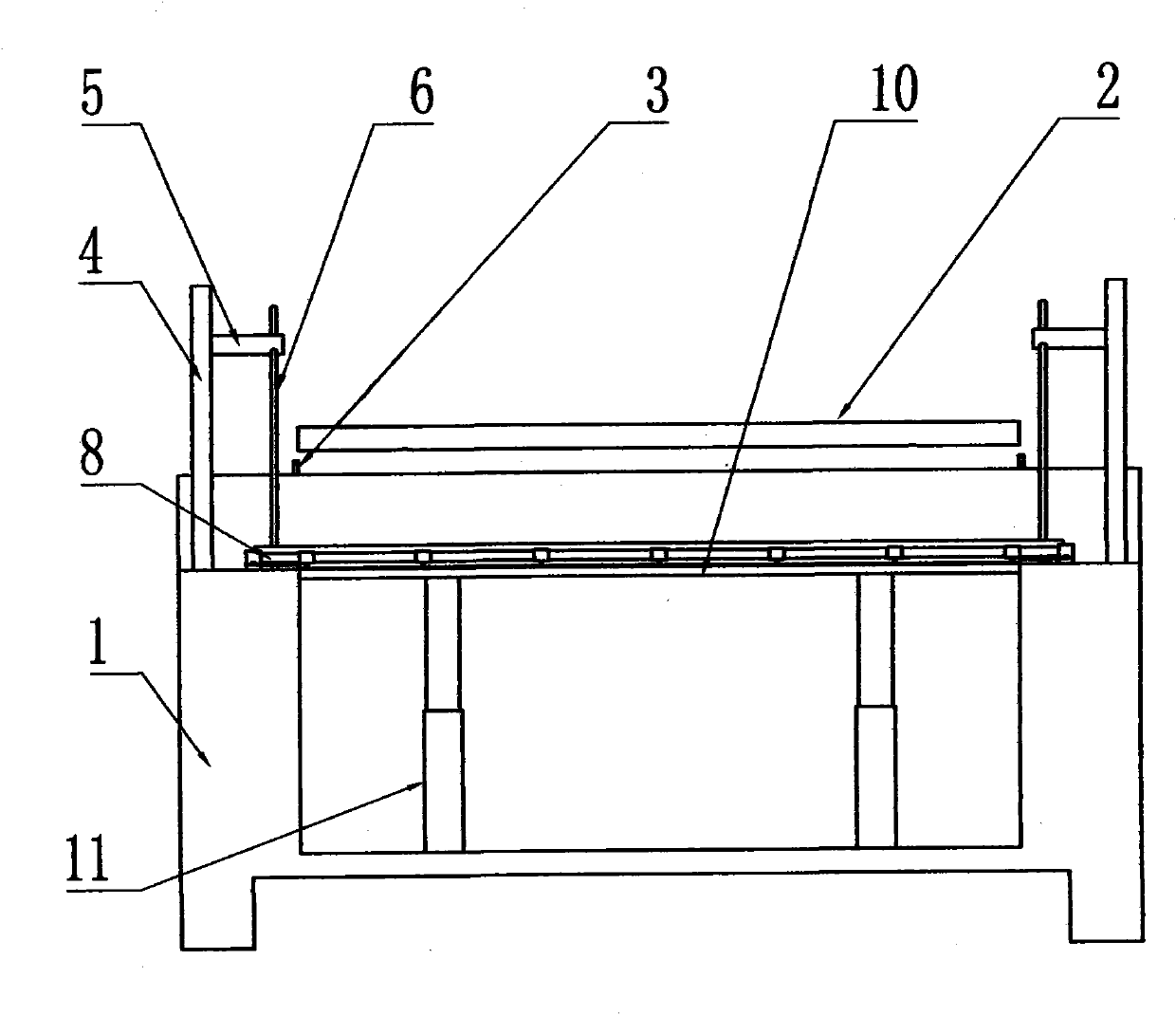

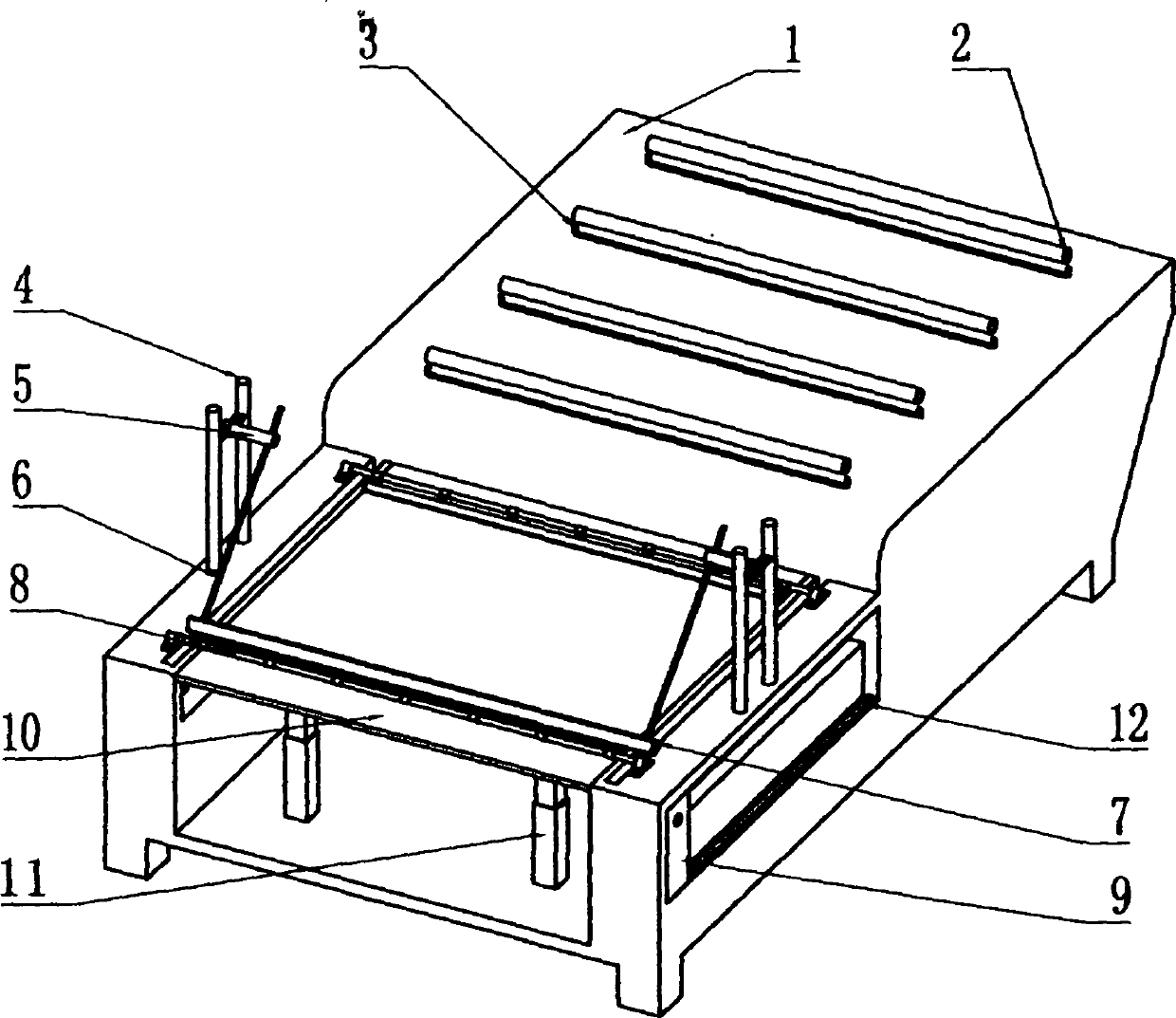

[0018] The specific implementation of the intelligent code cloth machine of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] Such as figure 1 , 2 As shown, it is a structural diagram of the intelligent code cloth machine of the present invention, that is, an intelligent code code machine, which includes a machine tool 1, cloth pulling equipment and code cloth equipment, and the cloth pulling equipment and code cloth equipment include a machine tool mounted on the machine tool 1 four sets of air pipes with small holes 2, limit controllers installed at both ends of the air pipe 2 3, servo motor 9, table 10, two rotating rod frames on both sides of the table 10 4, fixed on the rotating rod frame 4 The rotating rod 5, the two connecting rods 6 connected to the servo motor 9 at the other end of the rotating rod 5 on both sides of the table top 10, the slide rod 7 connected to the two connecting rods 6, and the two clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com