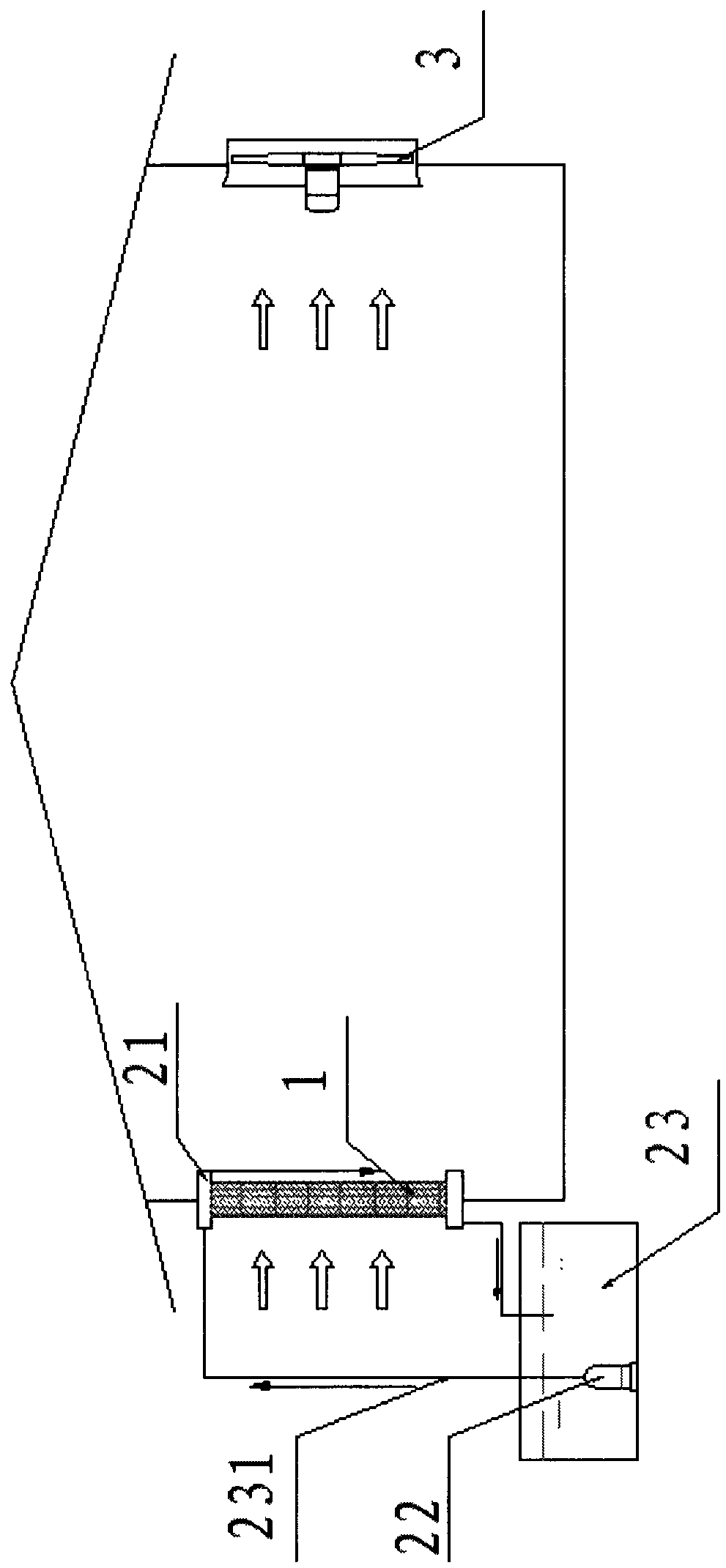

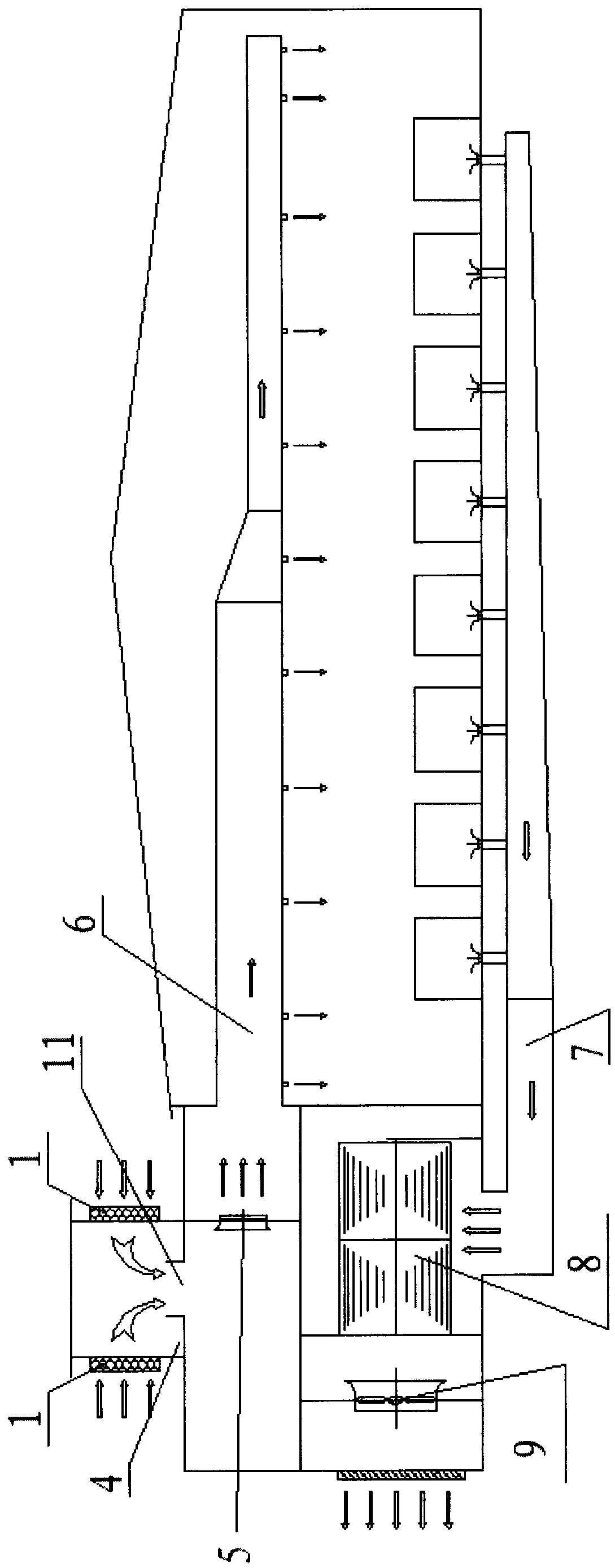

Novel wet curtain energy-saving textile mill air-conditioning system

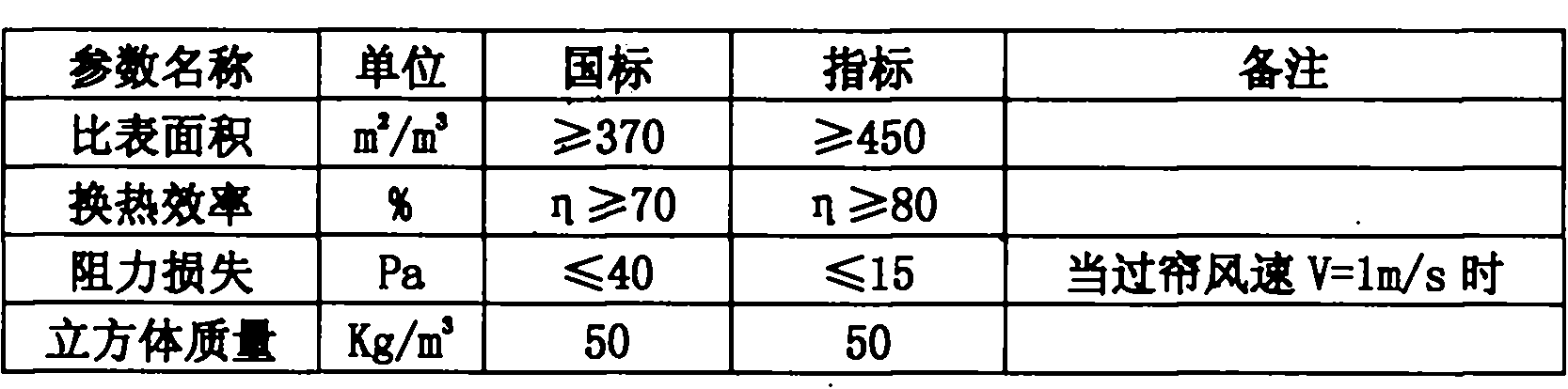

An air-conditioning system and a wet pad technology are applied in the field of new wet pad energy-saving textile air-conditioning systems, which can solve the problems of humidity drop, high wet pad humidity, and difficulty in keeping warm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] An enterprise in Xijiang has 192 air-jet weaving machines, with an installed power of 4kw per machine. The workshop is a steel structure factory building, surrounded by attached buildings. The workshop is 62m wide and 72.8m long. Workshop area 4613.6m 2 , roof slope 0.065. Outdoor design dry bulb temperature t n is 32°C. The relative humidity is 75%, and there are 18 people per shift in the workshop. Since there are attached rooms around the workshop,

[0083] Therefore, the heat input from the wall can be ignored, and only the heat input from the roof is considered. The roof is made of color steel tiles with a 10cm insulation layer, and the heat transfer coefficient is 0.43W / (m 2 ·°C).

[0084] Among them, cooling load calculation:

[0085] The heat Q transmitted from the enclosure structure into the room w =kF(t w -t n )=0.43×4513.6×4=7763.4W;

[0086] The incoming heat Q of solar radiation F =0.0404kF'ρJα=0.0404×0.43×4513.6×1058×0.5=41479W;

[0087] He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com