Graphene anti-corrosive paint, preparation method and management method

A technology of anti-corrosion coatings and management methods, applied in anti-corrosion coatings, coatings, instruments, etc., can solve problems such as inconvenient installation and operation, poor flexibility of epoxy resin, and low thermal efficiency of dryers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

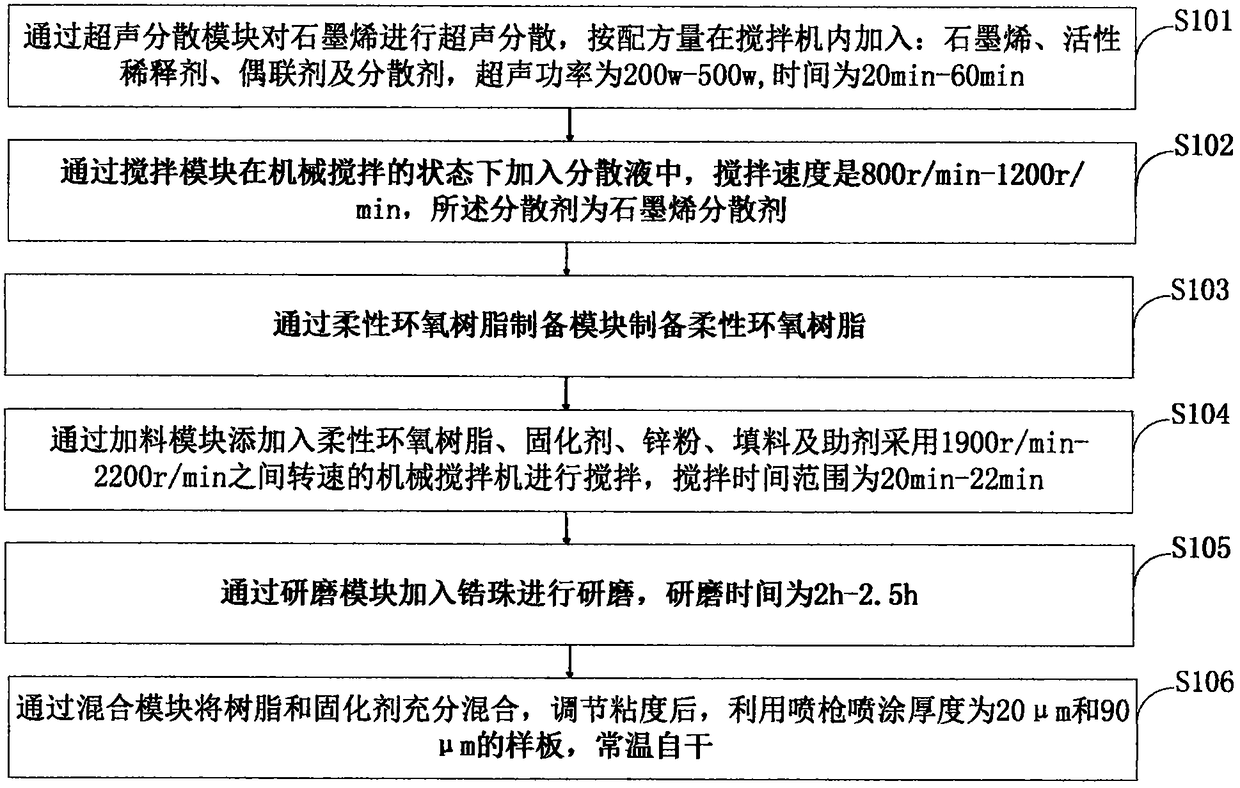

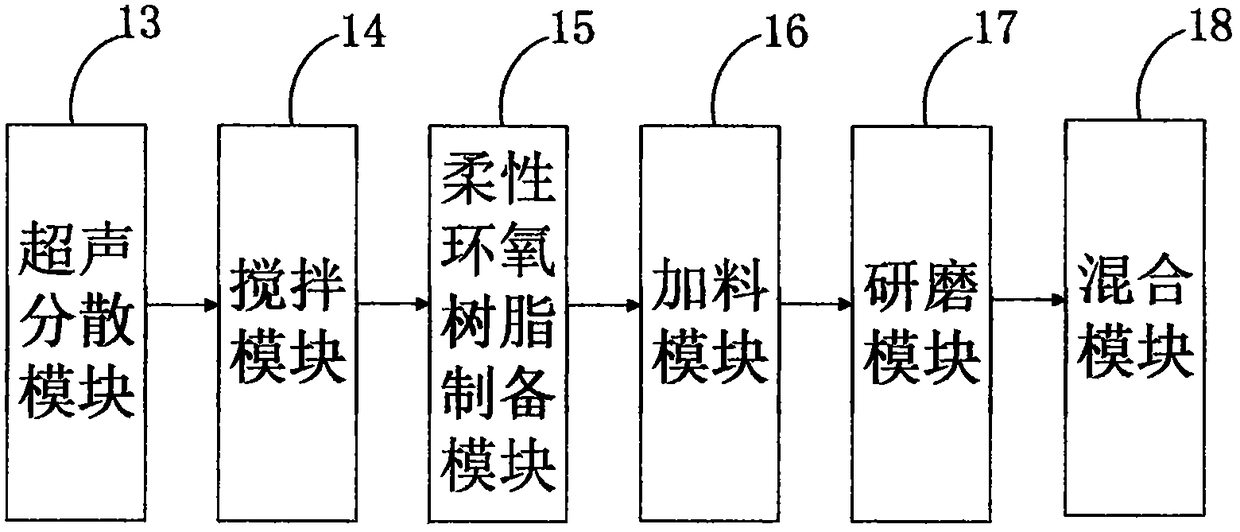

[0085] like figure 1 Shown, a kind of graphene anticorrosion paint preparation method provided by the invention comprises the following steps:

[0086] S101, ultrasonically disperse graphene through the ultrasonic dispersion module, add: graphene, active diluent, coupling agent and dispersant into the mixer according to the formula, the ultrasonic power is 200w-500w, and the time is 20min-60min;

[0087] S102, adding in the dispersion liquid under the state of mechanical stirring through the stirring module, the stirring speed is 800r / min-1200r / min, and the dispersant is a graphene dispersant;

[0088] S103, preparing a flexible epoxy resin through a flexible epoxy resin preparation module;

[0089] S104, add flexible epoxy resin, curing agent, zinc powder, fillers and additives through the feeding module, and use a mechanical mixer with a speed of 1900r / min-2200r / min to stir, and the stirring time range is 20min-22min;

Embodiment 1

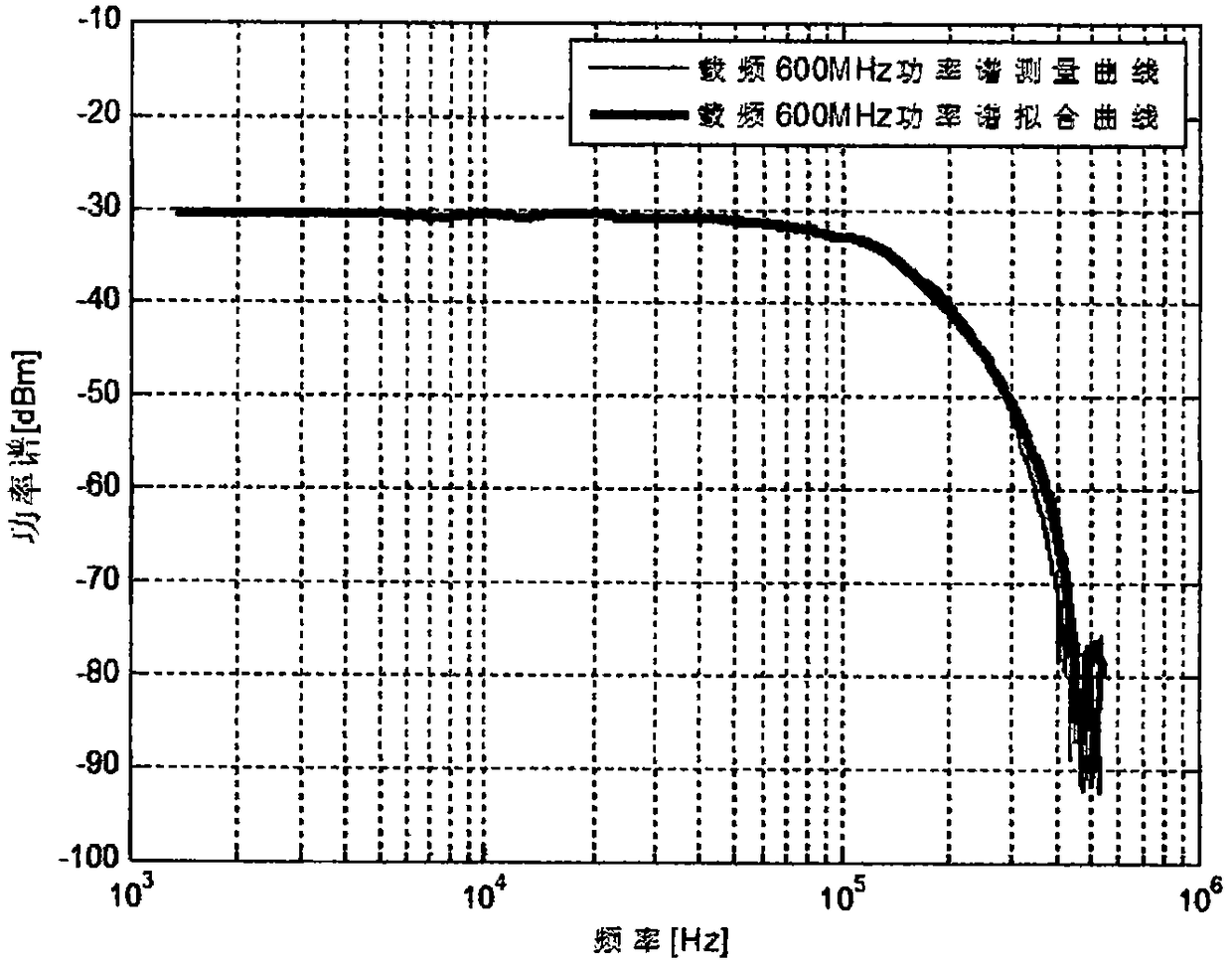

[0146] In the present embodiment, the carrier frequency of the measured signal is 600MHz, and the power spectrum of the measured signal is measured with a spectrum analyzer AV4036F, and the phase noise of the measured signal is calculated according to the method of the present invention using the power spectrum data measured, and the phase noise is given measurement results. And the phase noise measurement result of the algorithm of the present invention is compared with the direct measurement result of the phase noise measurement module of AV4036F to illustrate the implementation process and effectiveness of the method of the present invention.

[0147] image 3 The power spectrum curve of the measured signal measured by the spectrum analyzer AV4036F and the fitting result of the nonlinear least square method using the power spectrum measurement data are given. The phase noise coefficient of the measured signal obtained from the fitting result is:

[0148]

[0149]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com