Machining method for grinding main journal of crankshaft in floating mode

A processing method and technology of main journal, which are applied in the processing field of floating grinding crankshaft main journal, can solve the problems of precision damage, over-tolerance of more than 0.03 mm, deformation, etc., and achieve the effect of eliminating top tightening force and thermal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

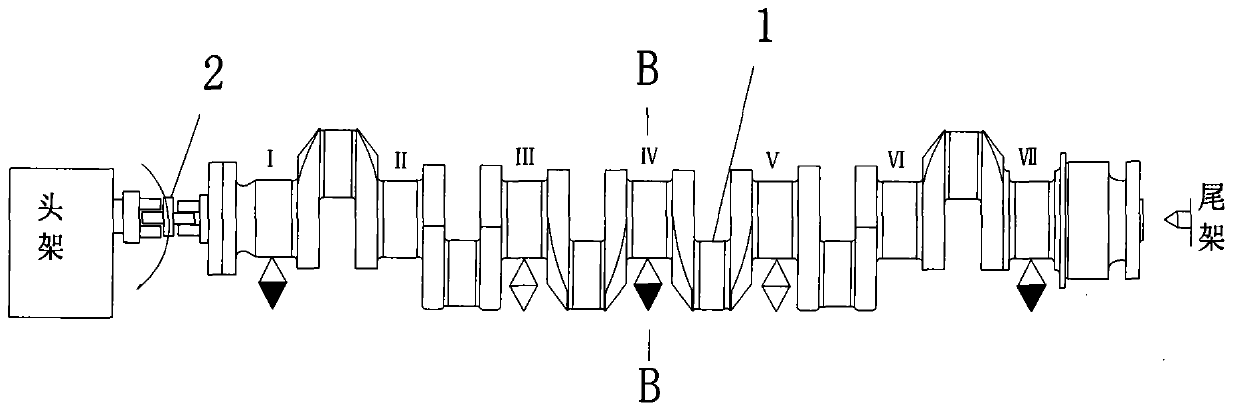

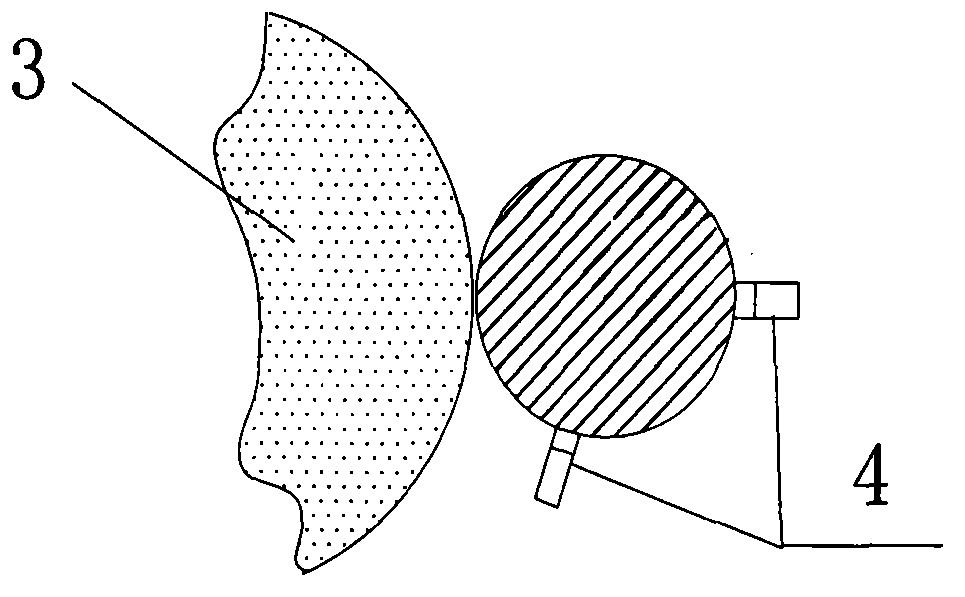

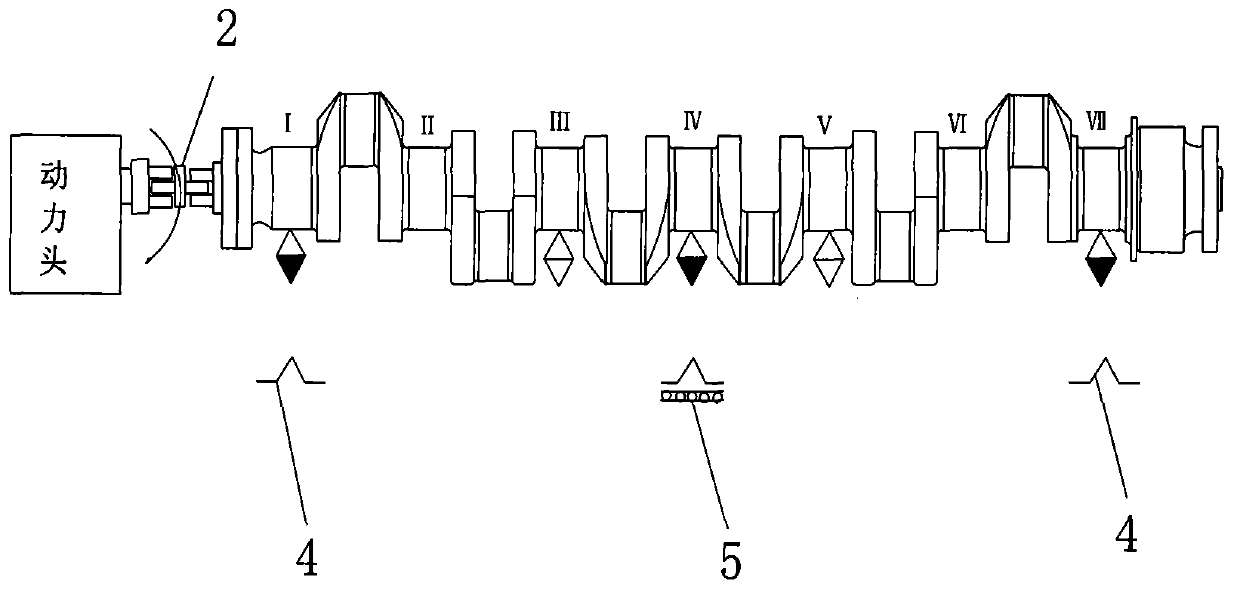

[0029] like figure 1 and figure 2 Shown, the processing method of floating grinding crankshaft main journal of the present invention, comprises the following steps:

[0030] S1: Clamping

[0031] After the two tops are ground, the main journal D=210.5mm, the universal coupling 2 is flexibly connected to the crankshaft, and the machine tool spindle drives the crankshaft to rotate through the universal coupling;

[0032] S2: Adjust the bracket support

[0033] Taking the six-throw crankshaft as an example, the I, IV, and VII gears of the main journal 1 are the reference support gears, that is, the above three gears are based on the same center, and the III and V gears are auxiliary support gears. For crankshafts with better rigidity, when machining It is not necessary, after the adjustment, the tailstock is loosened and does not push up, so that the crankshaft is in a natural state and is not affected by the axial force;

[0034] S3: coarse grinding

[0035] First, use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com