Compression mould with trapezoidal longitudinal guide lock structure

A lock structure and longitudinal technology, applied in the field of compression molds, can solve the problems of uneven manufacturing accuracy conditions of mold bases, difficulties in processing precision guide locks, and low mold positioning accuracy, so as to save mold installation and adjustment time, reduce production costs, The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

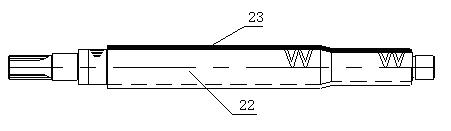

[0010] refer to figure 1 , the plastic part 23 covered by the insulating rotor shaft 22 is a typical representative of long-axis shaft thermosetting plastic parts. The material of the insulating layer is epoxy resin M-230. The main technical requirements are: the thickness of the plastic insulating layer is uniform, ensuring that the rotor shaft 22 Insulation performance requirements, the coaxiality of the journal and the insulating surface is 0.05mm.

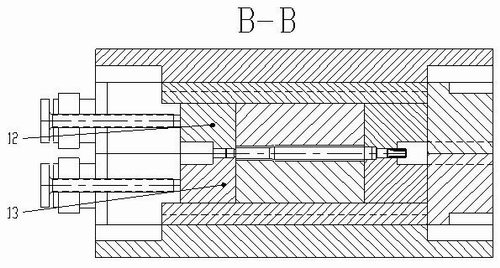

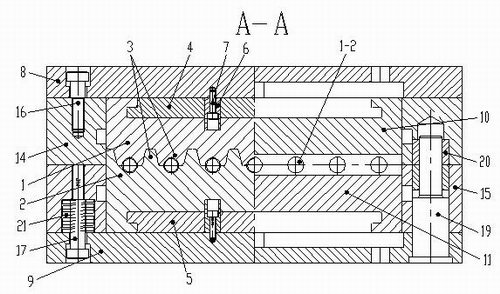

[0011] refer to Figure 2~4 , a compression mold with a trapezoidal longitudinal guide lock structure, comprising an upper mold 1 and a lower mold 2, characterized in that: the upper mold 1 and the lower mold 2 are respectively provided with a longitudinal Guided and positioned trapezoidal longitudinal guide locks 3 that lock and cooperate with each other, the upper end of the upper mold 1 is installed on the upper chute plate 4, the lower end of the lower mold 2 is installed on the lower chute plate 5, and the upper chute pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com