Upper die fixed type fin forming machine

A molding machine, fixed technology, applied in the directions of molding tools, positioning devices, feeding devices, etc., can solve the problems of inability to adjust, low guiding accuracy, etc., and achieve the effect of eliminating the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

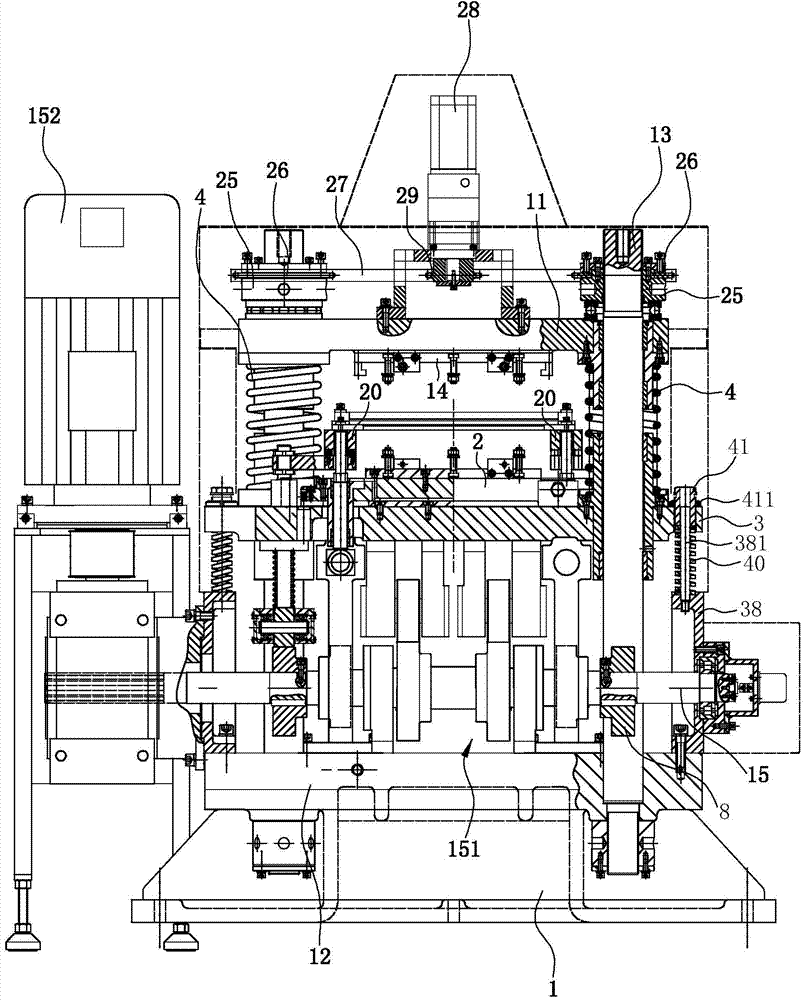

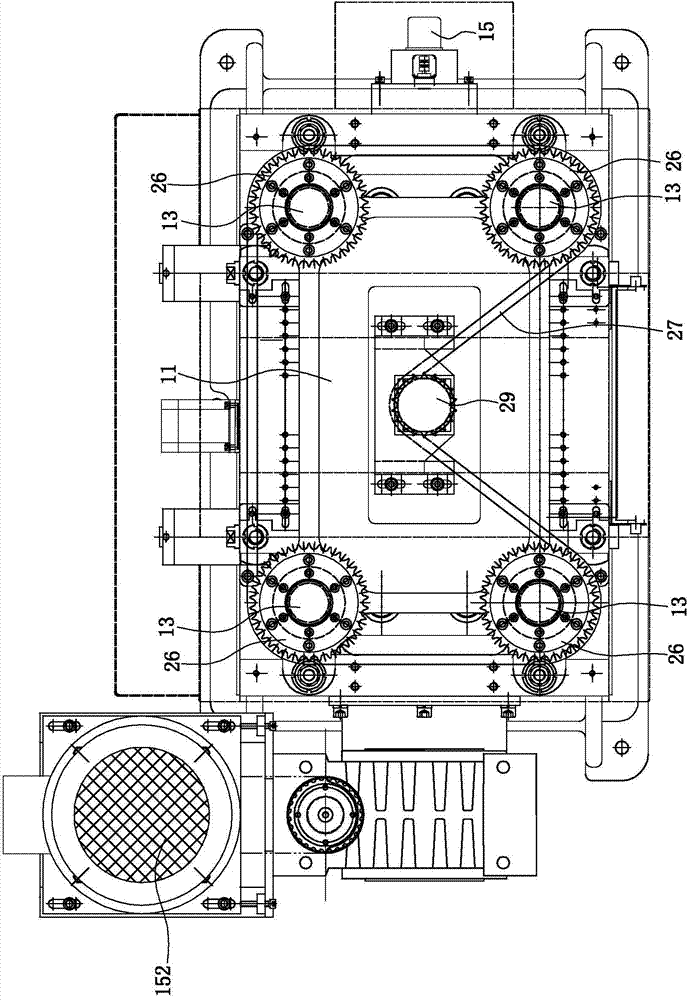

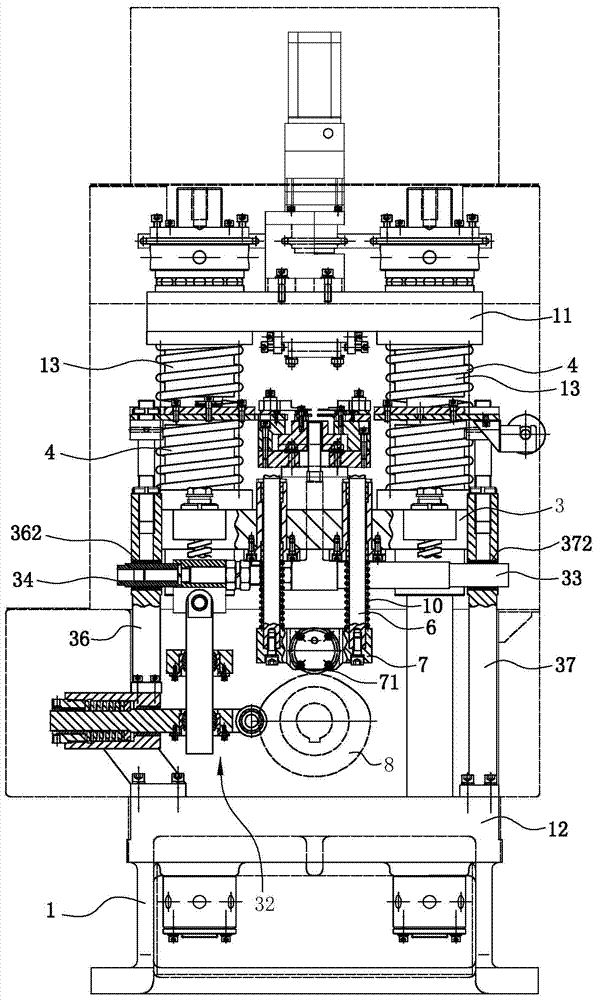

[0035] Such as Figure 1-13 Shown is a preferred embodiment of the present invention.

[0036] A fixed upper mold fin forming machine, comprising

[0037] Frame 1, it is made up of upper machine board 11, lower machine board 12 and the guide post 13 that is located between upper machine board 11 and lower machine board 12, upper machine board 11 can move up and down relative to guide post 13, upper machine board On the 11, a patrix mounting plate 14 is installed, and the patrix mounting plate 14 is used to fix the patrix, and the guide post 13 above the upper machine plate 11 is provided with a position-limiting structure that carries out upper limit to the upper machine plate 11.

[0038] Lower template 3 is located at the inner bottom of frame 1 and can slide up and down along guide pillar 13. Lower template 3 is provided with a lower mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com