Automatic guide measuring target and measuring system for shield machine

An automatic guidance and measurement system technology, applied in the field of measuring targets, can solve the problems of long time required, affecting the life of the instrument, and inability to complete the measurement, etc., and achieve the effects of low manufacturing and maintenance costs, precise angle measurement function, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

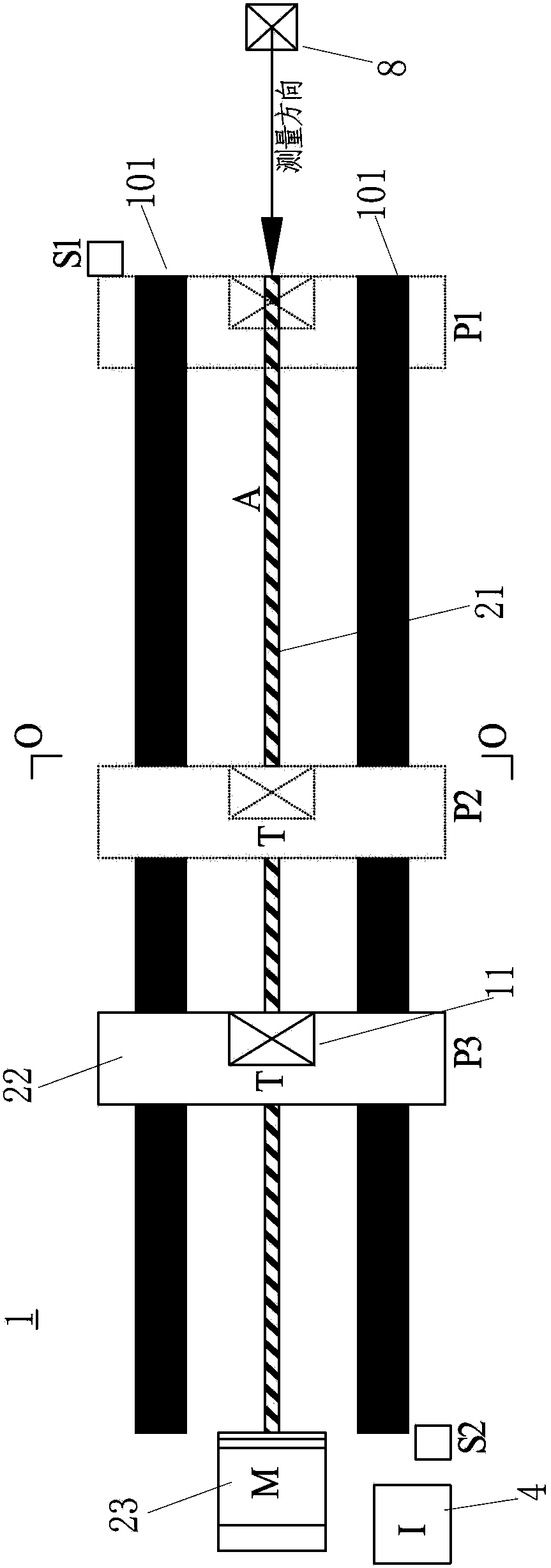

[0032] The present invention is described further below in conjunction with embodiment and accompanying drawing.

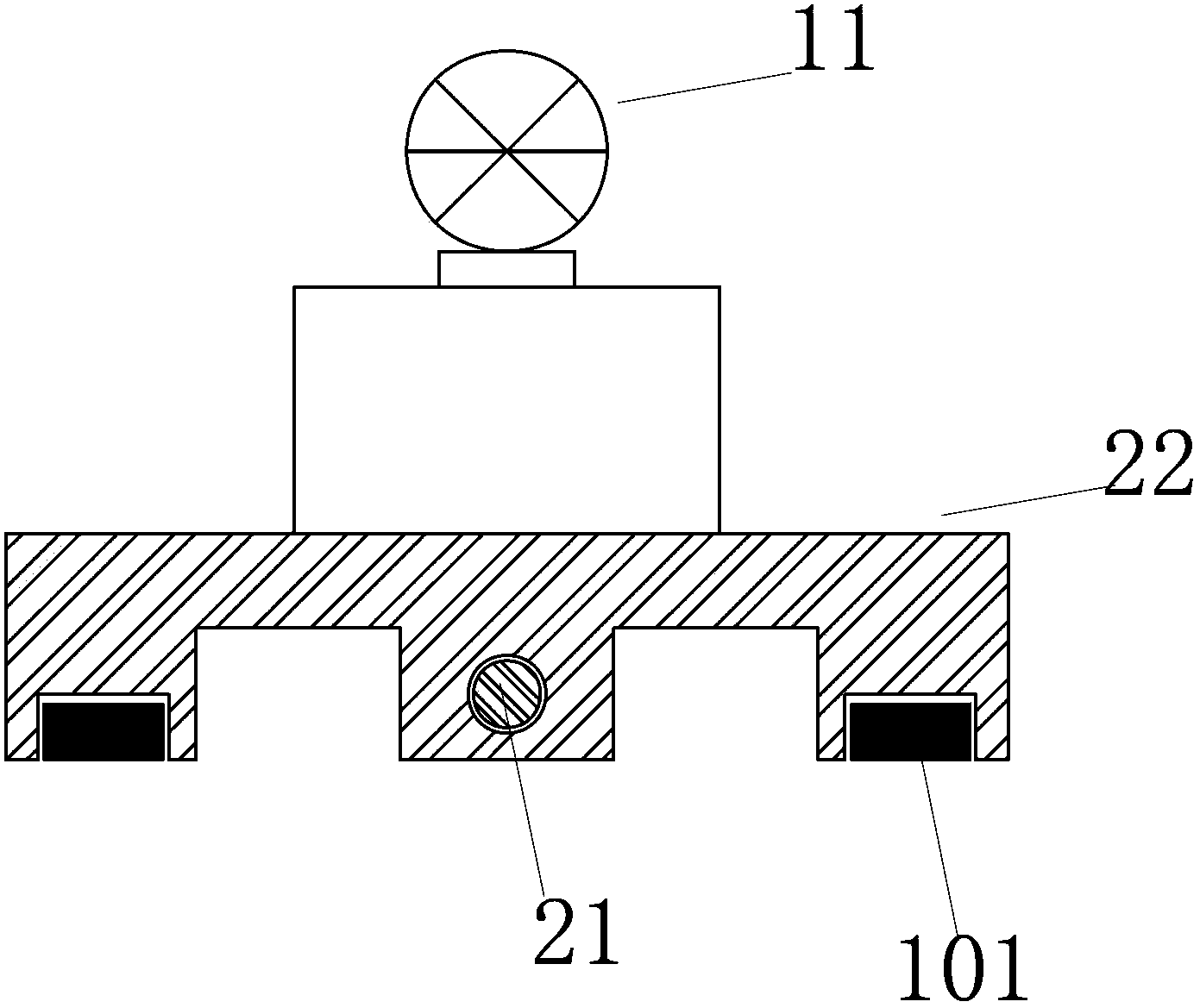

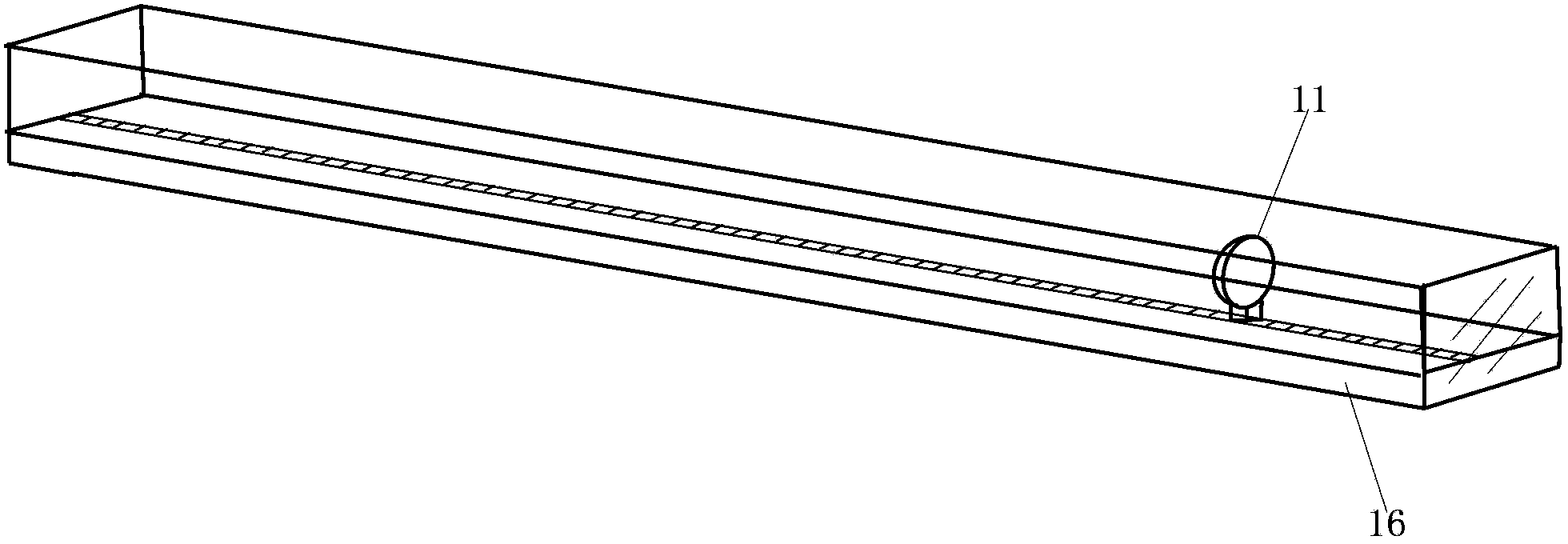

[0033] The automatic measurement target 1 of the present invention includes a target prism 11 that can move along a linear coordinate. The spatial relationship between the linear coordinate and the axis 90 of the shield machine is known. The target prism 11 can stay at any position on the linear coordinate. The driving mode of the target prism 11 includes two types, one is to be driven to reach a designated position, and the other is to be driven to a non-designated position, but the position of the target prism relative to the linear coordinates can be measured or calculated, Or combine the above two driving methods.

[0034] To drive the target prism to move along a fixed linear coordinate, and to stay at a specified position on the linear coordinate, those skilled in the art can use other existing means to realize it. However, the present invention provides a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com