Diamond grinding wheel induction brazing device and brazing method

A diamond grinding wheel and induction brazing technology, which is applied in auxiliary devices, metal processing, welding equipment, etc., can solve problems such as low brazing efficiency, large heat-affected area, and thermal deformation of the substrate, achieving fast heating speed and ensuring uniformity , the effect of heating concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

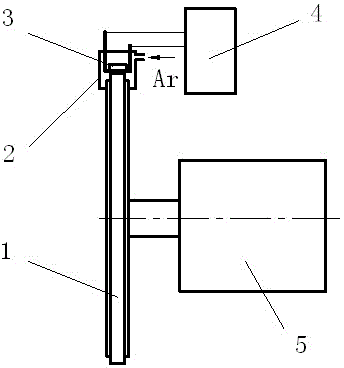

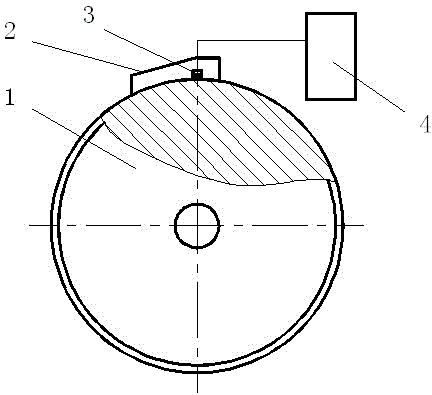

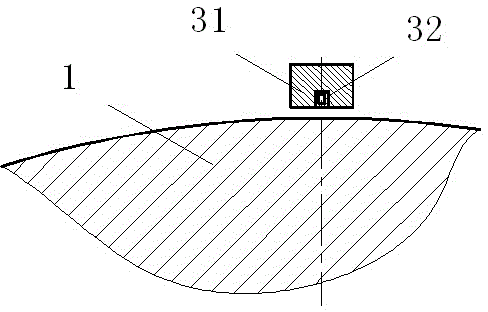

[0022] The method for ultra-high-frequency induction brazing of diamond grinding wheel of the present invention adopts an ultra-high-frequency induction heating power supply with fast heating speed, local heating, and a frequency of 1 MHz as its heat source, and the shape of the induction coil is a single-circuit line, which can affect the work of the grinding wheel substrate. The surface is heated linearly. During the heating process, the grinding wheel base rotates slowly at a constant speed, so that the grinding wheel base is continuously brazed by linear heating combined with relative scanning movement. When the grinding wheel base rotates once, the brazing of the entire diamond grinding wheel is completed.

[0023] The device of diamond grinding wheel ultra-high frequency induction brazing of the present invention, as Figure 1-Figure 3 As shown, it includes a grinding wheel base 1, a grinding wheel turning device 5, an ultra-high frequency power supply 4, an induction coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com