A paper sheet thickness detection device and a note processing device

A technology for thickness detection and paper sheets, which is applied in the field of paper sheet thickness detection devices, can solve the problems of not considering the change of detection sensitivity, not considering the thermal deformation of the shell, etc., and achieve the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

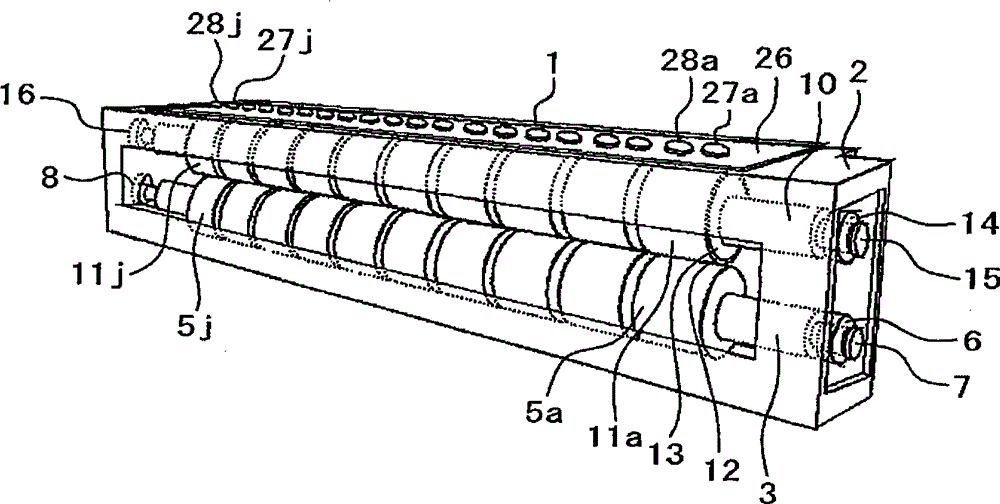

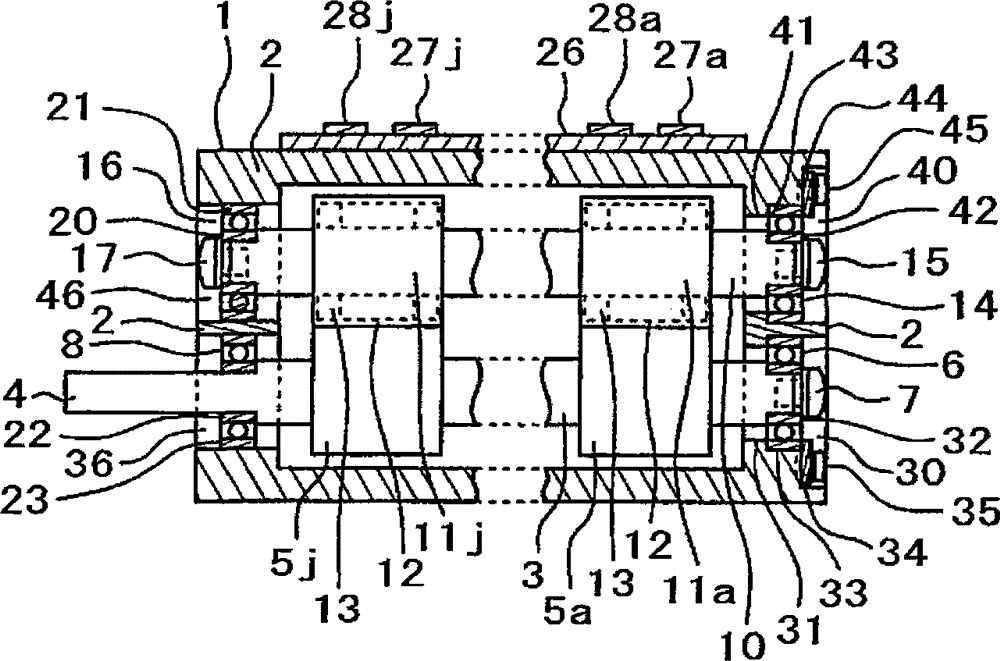

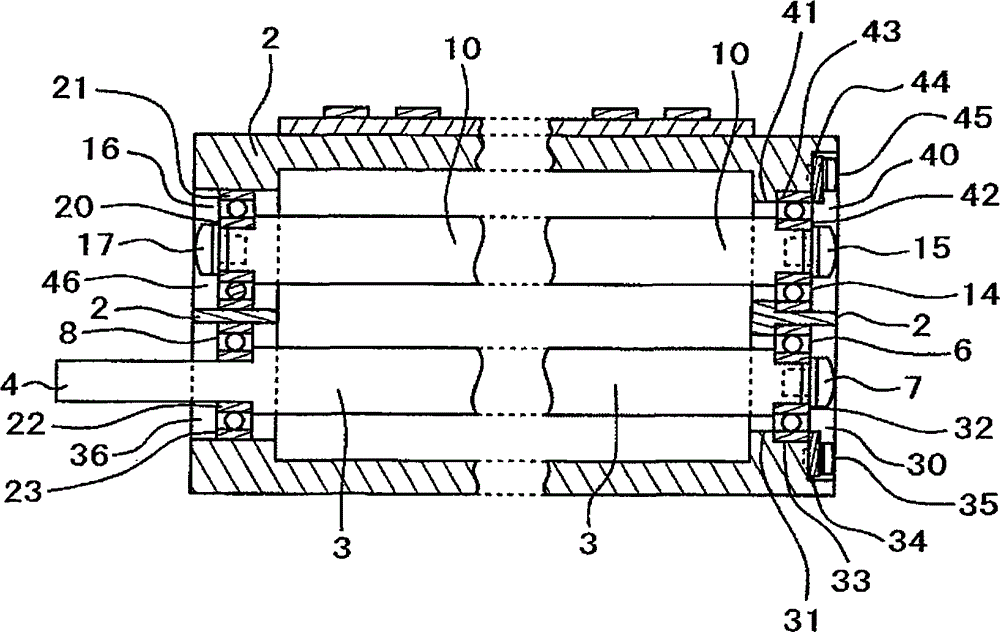

[0040] use figure 1 , figure 2 , image 3 The sheet thickness detecting device according to the embodiment of the present invention will be described.

[0041] figure 1 It is an overview diagram showing a general configuration of a sheet thickness detection device.

[0042] figure 2 yes figure 1 Cross-sectional view of the thickness detection device.

[0043] image 3 will be figure 2 Enlarged image.

[0044] exist figure 1 , figure 2 Among them, the sheet thickness detection device 1 is provided with reference rollers 5 a to 5 j that rotate by transmitting a rotational force through a rotational drive mechanism (not shown). The reference rollers 5 a to 5 j are provided on the rotating shaft 3 . The detection rollers 11a to 11j are provided on the rotating shaft 10 and rotate in a driven manner with the rotation of the reference rollers 5a to 5j. The thickness of the sheet is detected by the detection rollers 11a to 11j moving upward according to the thickness o...

Embodiment 2

[0059] use Figure 4 Embodiment 2 of the present invention will be described. Furthermore, due to the figure 2 The same reference numerals denote the same components, so descriptions thereof will be omitted.

[0060] exist Figure 4 In this embodiment, the frame 2 made of aluminum is changed to one made of resin in consideration of cost reduction, and the metal parts 50 and 51 are insert-molded on the resin frame 2 . Thereby, the resin frame 2 and the metal members 50 and 51 are combined and integrated.

[0061] That is to say, on the metal parts 50, 51 there are figure 2 The mounting holes 30 , 40 , 36 , 46 of the ball bearings penetrating the metal members 50 , 51 are identical, and the mounting holes 30 , 40 are provided with screw holes for steps 31 , 41 and stop screws 35 , 45 . The metal members 50, 51 are preferably made of the same material as the ball bearings 6, 8, 14, 16, or materials with the same or close coefficient of thermal expansion. Specifically, alu...

Embodiment 3

[0067] use Figure 5 Other embodiments of the present invention will be described. Furthermore, due to the figure 2 The same reference numerals denote the same components, so descriptions thereof will be omitted.

[0068] Figure 5 is to make Figure 4 The metal parts 50 and 51 shown are the other metal parts 52 and 53 and are fixed to the resin frame 2 by set screws 54 , 55 , 56 and 67 . In addition, metal parts 52, 53 are provided with figure 2 The mounting holes 30, 40, 36, 46 of the same ball bearings that pass through the metal parts 52, 54 are provided with the threaded holes of the level difference 31, 41 and the stop screw 35, 45, and the supply and stop in the mounting holes 30, 40. The through hole that movable screw 54,55,56,57 inserts. In addition, the metal members 52, 53 are preferably made of the same material as the ball bearings 6, 8, 14, 16, or materials with the same or close coefficient of thermal expansion. Specifically, aluminum, stainless steel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com