Winding length counter wheel of winding machine

A technology of counting wheel and winding machine, applied in measuring devices, instruments, electrical components, etc., can solve problems such as affecting the appearance quality of copper core wires and extrusion deformation of plastic sheaths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

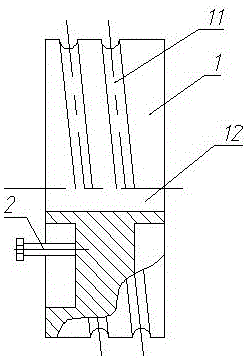

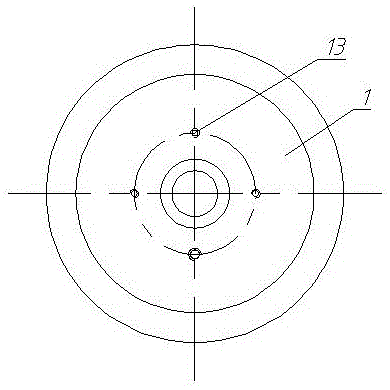

[0009] Below in conjunction with accompanying drawing, the winding length counting wheel of a kind of winding machine of the present invention is further described:

[0010] Depend on figure 1 and figure 2 Visible, the present invention it comprises counting wheel 1 and screw 2, and the outer cylindrical surface of described counting wheel 1 is provided with spiral groove 11, and described spiral groove 11 is semicircular, and the radius of spiral groove 11 is 3~8mm 1. The axial spacing of the spiral grooves 11 is 15-20mm, and the rise angle of the spiral grooves 11 is 6-8°; the counting wheel 11 is provided with a bearing hole 12, and the side of one end of the counting wheel 11 is provided with four equiangular angles. There are two screw holes 13, and a screw 2 is arranged in one of the screw holes 13.

[0011] The installation method of the present invention is that the counting wheel 1 is first installed on the fixed shaft through the bearing, and then the copper core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com