Combined type pallet for brake wheel

A composite, backing disc technology, which is applied in the direction of brake discs, mechanical equipment, brake components, etc., can solve the problems that the separation of cylinder block components cannot be satisfied, and achieve the elimination of partial wear of the brake disc and the breaking of the indicator rod, and the elimination of material Effect of thermal deformation and enhanced heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

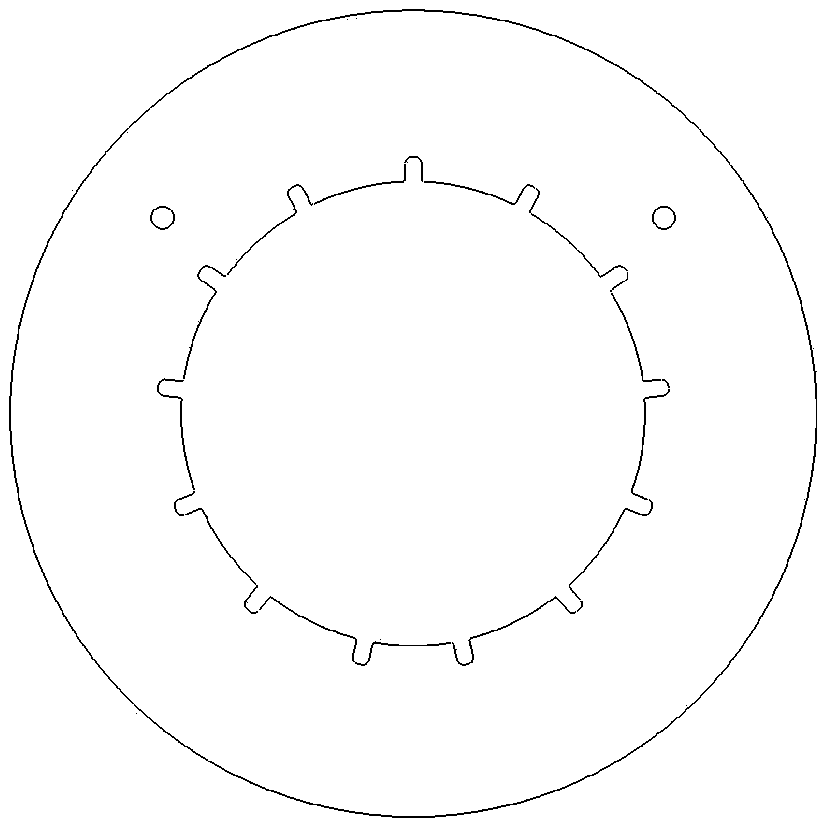

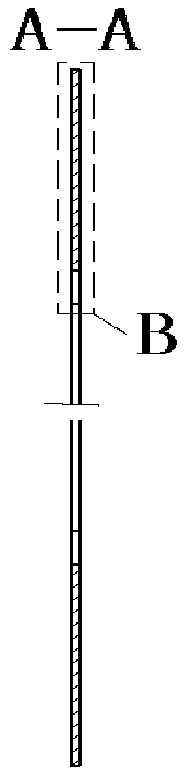

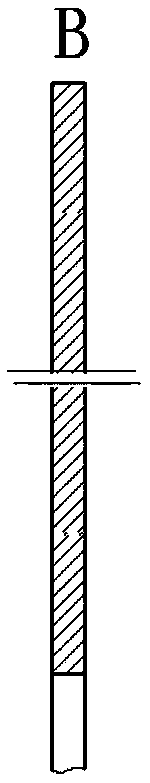

[0054] This embodiment is a composite pad for a certain type of machine brake device, including a welding assembly 5 and a plurality of gasket groups; each gasket group is composed of an inner gasket 6 and an outer gasket 7 . Each gasket group is loaded into each gasket mounting hole on the disc surface of the welding assembly 5 respectively; the inner gasket 6 in the gasket group is located on the side where the welding assembly has a heat insulator, and the inner gasket The small outer diameter end of the inner gasket is sequentially loaded into the inner gasket via hole in the center of the pad 4, the inner gasket via hole in the center of the heat insulating part 2, and the gasket installation hole in the center of the frame 1, so that the outer circumferential surface of the inner gasket is stepped The end surface of the outer gasket 7 is fitted to the end surface of one end of the skeleton 1 in the welding assembly 5; the outer gasket is located on the other side of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com