Device for unifying length of ejector sleeve

A technology of spool and push tube seat is applied in the field of devices for unifying the length of the spool and push tube, which can solve the problems of large maintenance, high comprehensive product cost, low production efficiency, etc., so as to prolong the service life, reduce the comprehensive cost, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

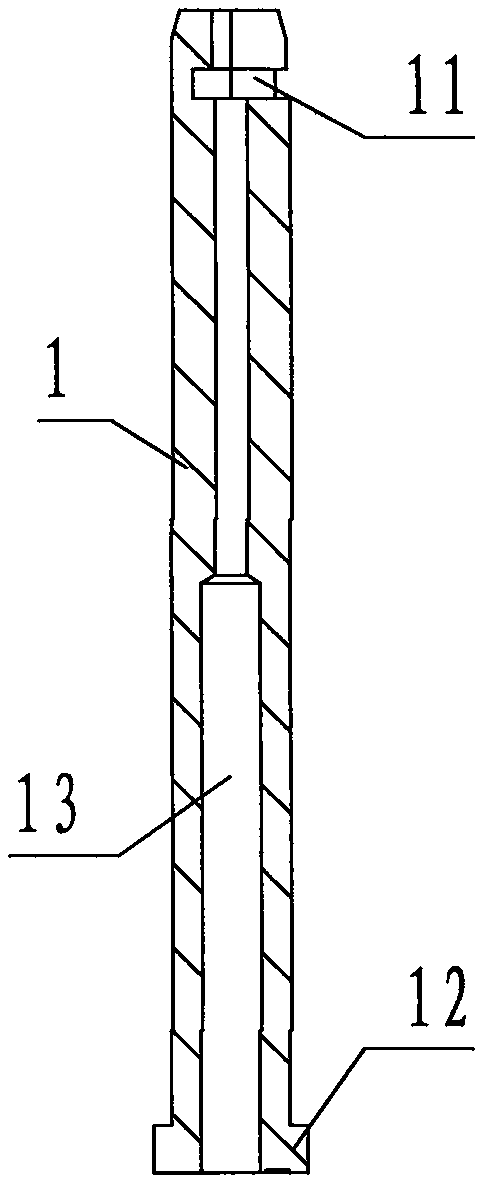

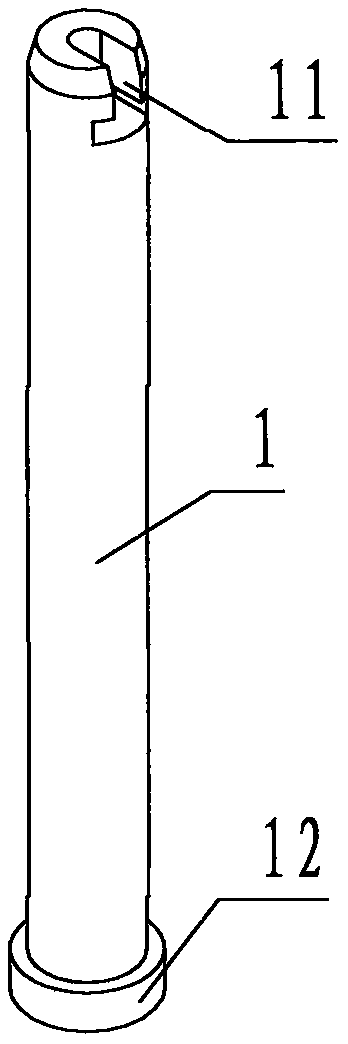

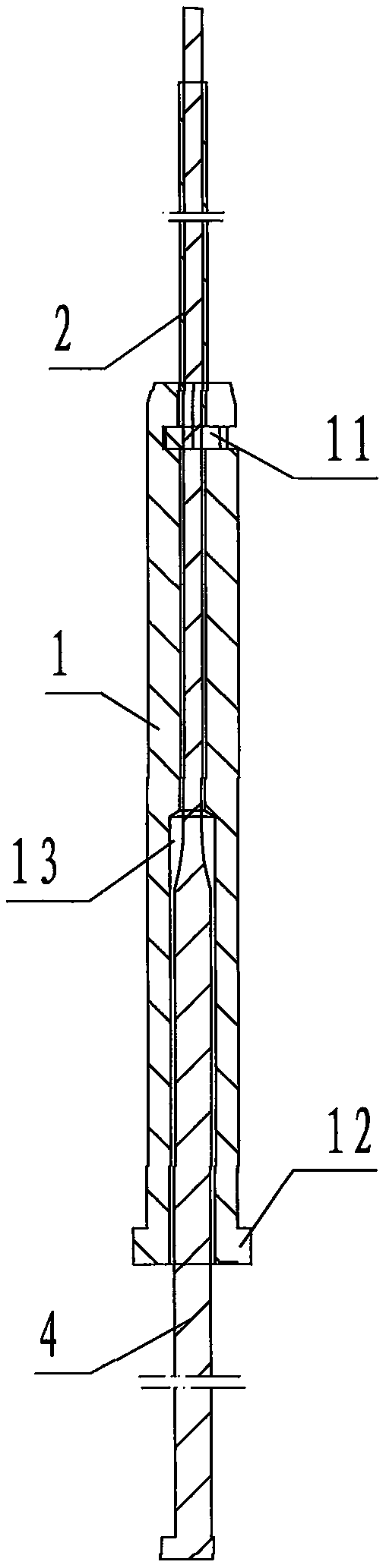

[0025] refer to Figure 1 ~ Figure 4 , a device for unifying the length of the barrel push tube of the present invention, comprising a push tube seat 1, a fixed-length push tube 2 and a tube seat sliding sleeve 3, wherein: the push tube seat 1 is a cylindrical tubular steel Components, the upper end of the push tube base 1 is provided with a connection port 11 for buckle connection to the fixed-length push tube 2, the lower end of the push tube base 1 is provided with a flange step called a seat 12, and the inner cavity of the push tube base 1 is the upper The passage of small lower big cylindrical step shape is called core slideway 13;

[0026] The fixed-length push tube 2 is a short specification push tube with a short length among many length specifications of the tube push tube in the prior art;

[0027] The tube seat sliding sleeve 3 is a cylindrical tubular steel member;

[0028] In application, there are cylindrical step holes in the upper and lower directions, small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com