Face-down bonding technique capable of preventing electric resistance welding parts from deforming

A welder and process technology, applied in the field of reverse welding technology, can solve problems such as workpiece deformation, achieve the effect of eliminating thermal deformation and mechanical deformation, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Embodiment: making plate evaporator plates of an alumina plant.

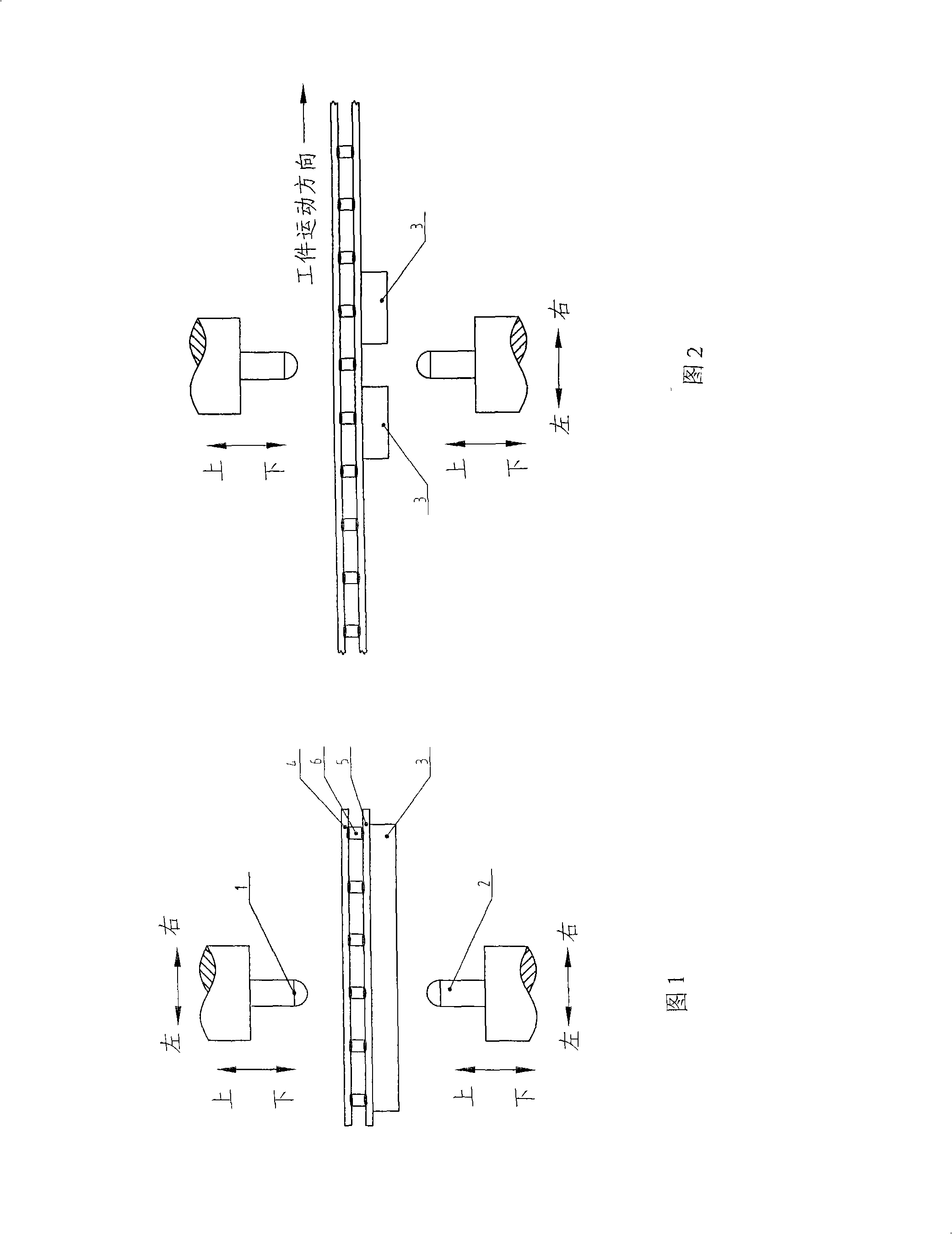

[0017] As shown in Figures 1 and 2, first, install the workpiece platform 3 under the workpiece; then place the plates 4 and 5 on the horizontal plane of the platform 3; after loading the welding stud 6 and positioning it, the upper electrode 1 is first pressed down to press the plate 4 and 5 are on the workpiece platform 3; the lower electrode 2 rises again to press the workpiece tightly; the electrodes 1 and 2 discharge and weld; the welding stud is both the workpiece and the electrode in the formed circuit during discharge. When welding, the wind direction of the axial blower installed on the upper and lower sides of the plates 4 and 5 is aligned with the welding position and the direction of the welded plates, and the welding position is mainly used to cool the solder joints by blowing air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com