Assembled high protection photovoltaic combiner box

A photovoltaic combiner box, high-protection technology, applied in the direction of electrical components, substation/switch layout details, etc., can solve the problems that the welding seam cannot adapt to the harsh environment, unfavorable product quality stability, and cannot be well remedied, so as to reduce the protection Area range, excellent physical and mechanical properties, and the effect of solving the problem of wall-mounted installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

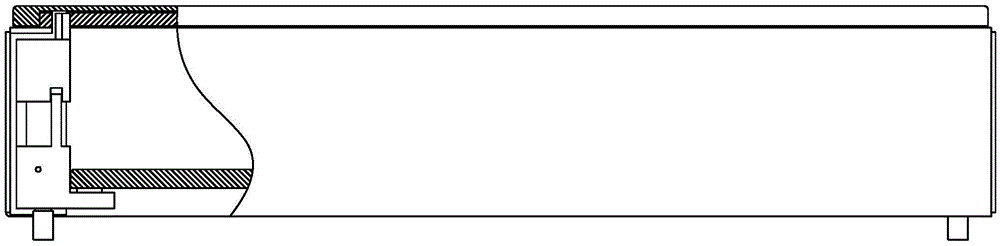

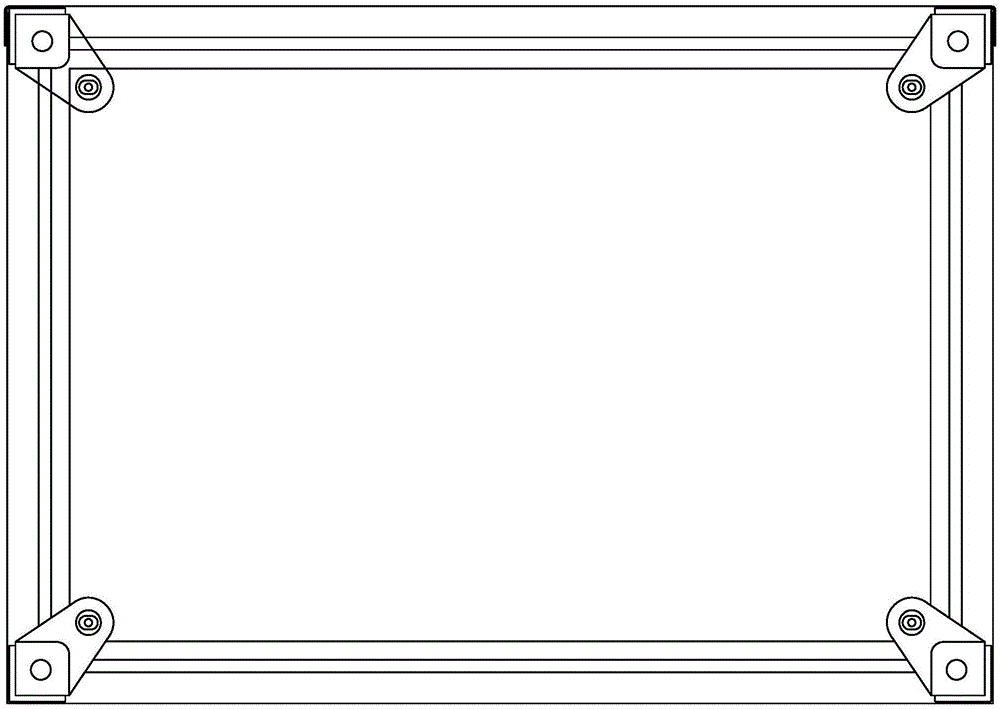

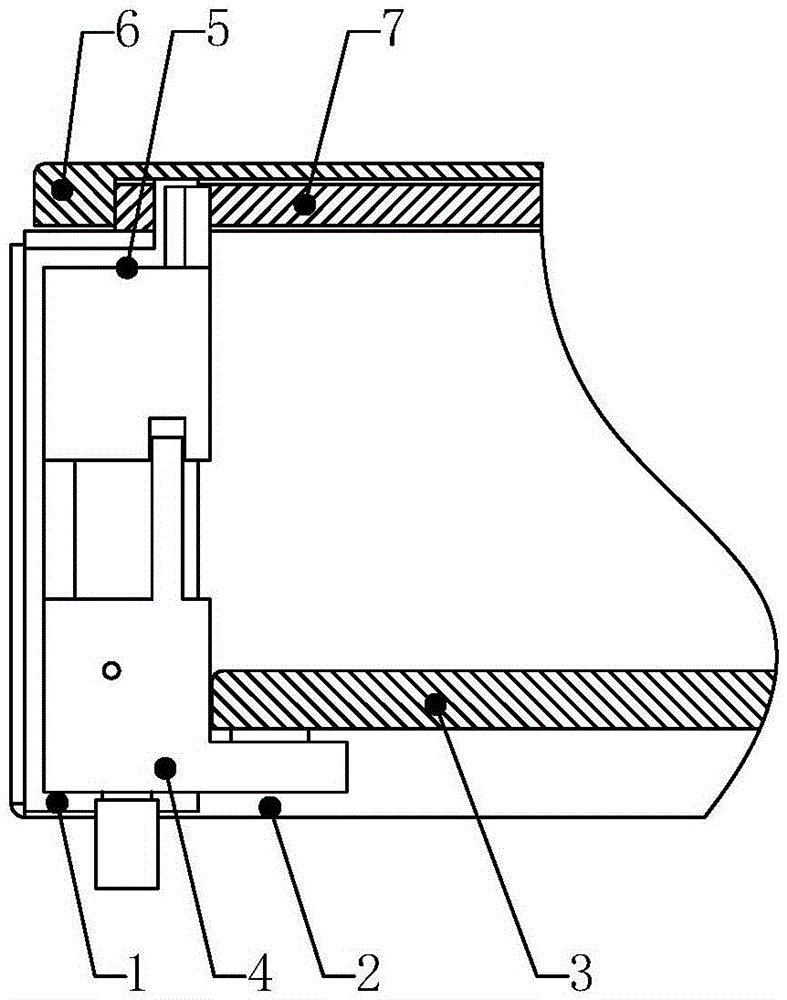

[0039] This embodiment provides an assembled high-protection photovoltaic combiner box, the structure of which is as follows figure 1 , figure 2 and image 3 As shown, it includes a box body 2, a mounting plate 3 and a door panel 6. The box body 2 is a rectangular frame structure with openings on both sides. Bracing 4 and front gusset 5, the four corners of the box body 2 are respectively provided with sealing corner pads 1, and the rear gusset 4 and front gusset 5 are installed in the sealing corner pad 1;

[0040] The sealing corner pad 1 is a square column structure arranged vertically, two adjacent side openings of the square column structure, and a protruding short column is arranged on the upper end surface of the square column structure at the junction of the two adjacent opening sides, and the sealing corner pad 1 Connect the box body 2 by bonding;

[0041]The front gusset 5 is a cube set vertically, and a corner of the upper surface of the cube is vertically provi...

Embodiment 2

[0045] This embodiment provides a method for installing an assembled high-protection photovoltaic combiner box, including the following specific steps:

[0046] Step 1: Utilize the mechanical processing characteristics of sheet metal to stamp a flat plate into a specific shape through CNC stamping, and then process it into one body through sequential bending to obtain the box body 2;

[0047] Step 2: Put the formed box body 2 into a specific assembly mold, and paste four sealing corner pads 1 on the four corners of the casing;

[0048] Step 3: Fix the four rear gussets 4 to the rear four corners of the box body 2 with bolts and nuts; similarly, fix the four front gussets 5 to the front four corners of the box body 2 with bolts;

[0049] Step 4: Finally assemble the door lock, hinge, mounting plate 3, door panel 6, door panel sealing strip 7 and components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com