Multipath hydraulic change-over valve

A technology of hydraulic reversing valve and one-way valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

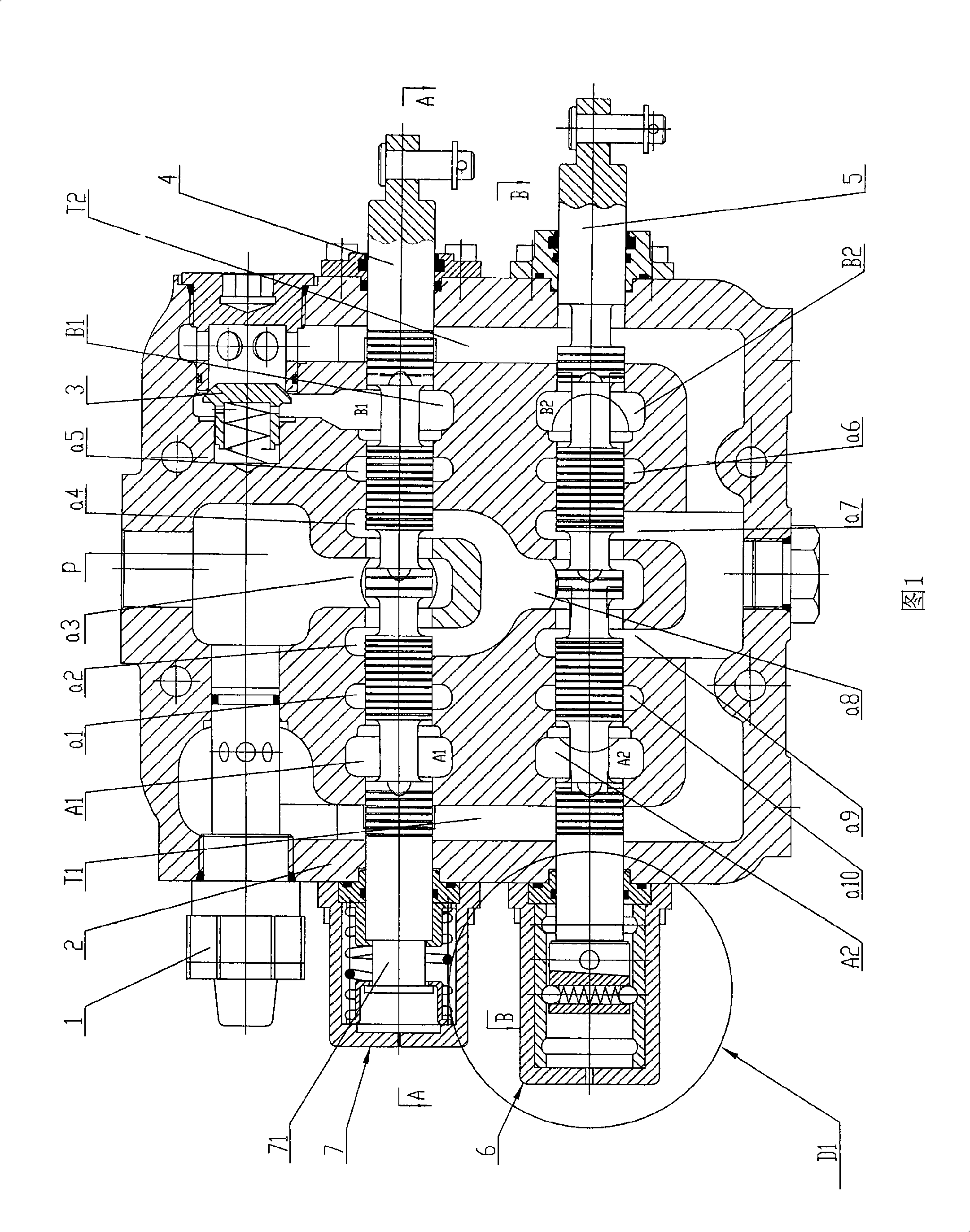

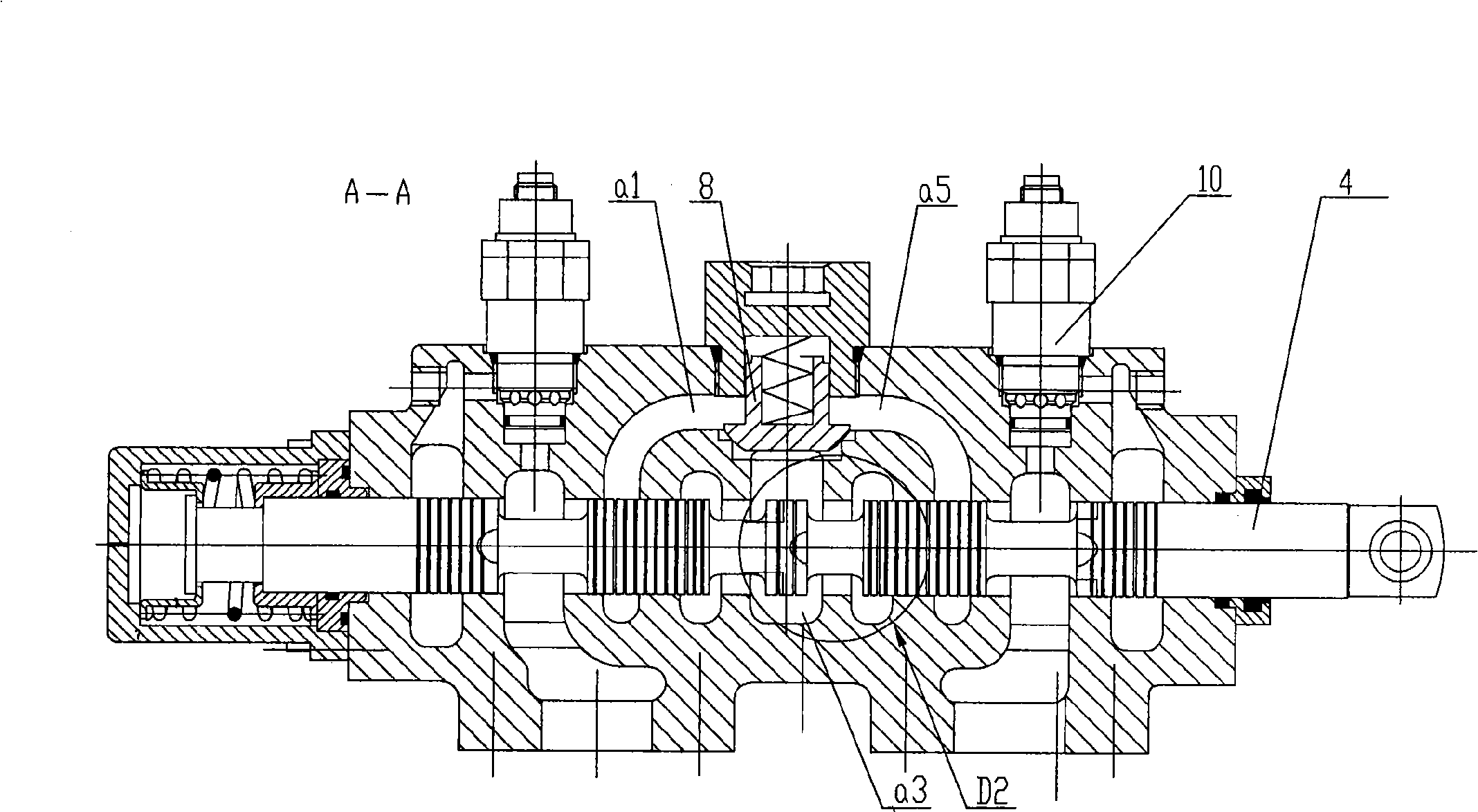

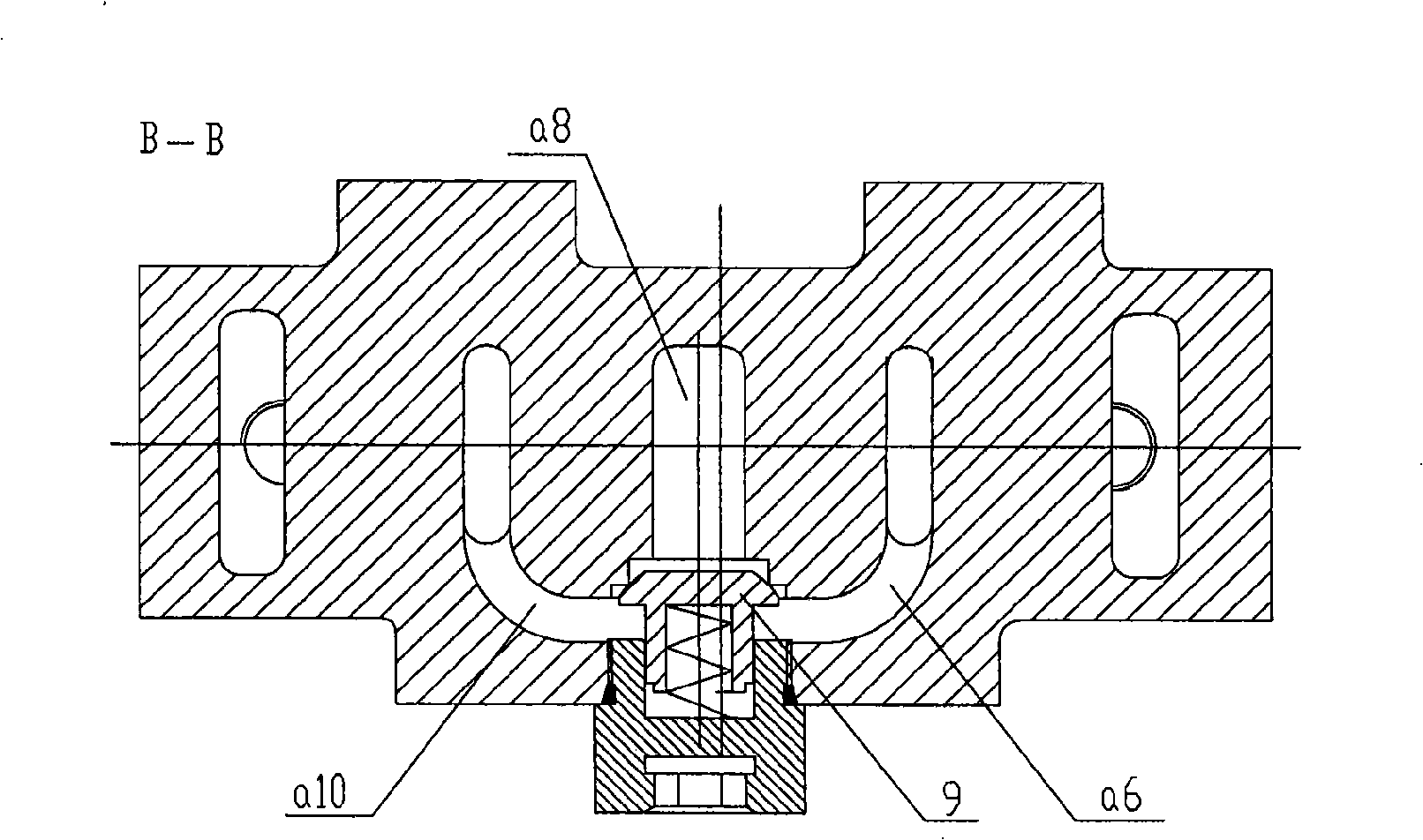

[0025] Referring to Figure 1- image 3 , multi-way hydraulic reversing valve, including valve body 2, bucket valve stem 4, boom valve stem 5, main safety valve 1, overload valve 10, bucket load holding check valve 8, boom load holding check valve 9. Oil supply valve 3, rotary bucket valve stem positioning device 7, boom valve stem positioning device 6, etc., valve body 2 is provided with 9 oil passages respectively on the rotary bucket joint valve stem hole and the boom joint valve stem hole, The oil passages on the stem hole of the bucket union are, from left to right, the left return oil passage T1, the left working port oil passage A1, the left working port oil inlet passage a1, the left unloading oil passage a2 of the bucket union, The oil inlet passage a3 of the bucket union, the right unloading oil passage a4 of the bucket union, the oil inlet passage a5 of the right working port, the oil passage B1 of the right working port, the right return oil passage T2, and the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com